Method for reducing petrol engine low-temperature starting-up time

A low-temperature starting technology for gasoline engines, applied in engine control, machines/engines, mechanical equipment, etc., can solve the problems of long engine starting time, wasting gasoline polluting the environment, and easily causing cylinder flooding, etc., to increase the amount of gasification, Increase the number of fires and reduce the effect of wall dampness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

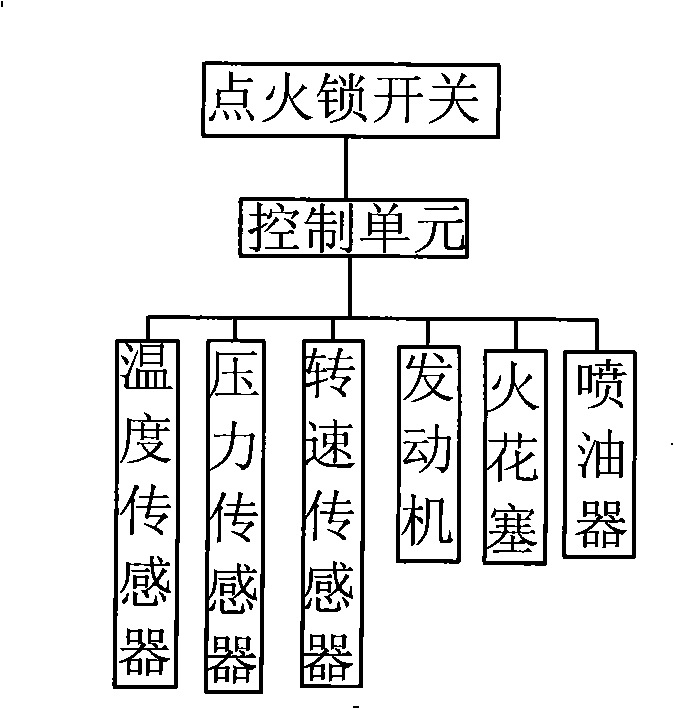

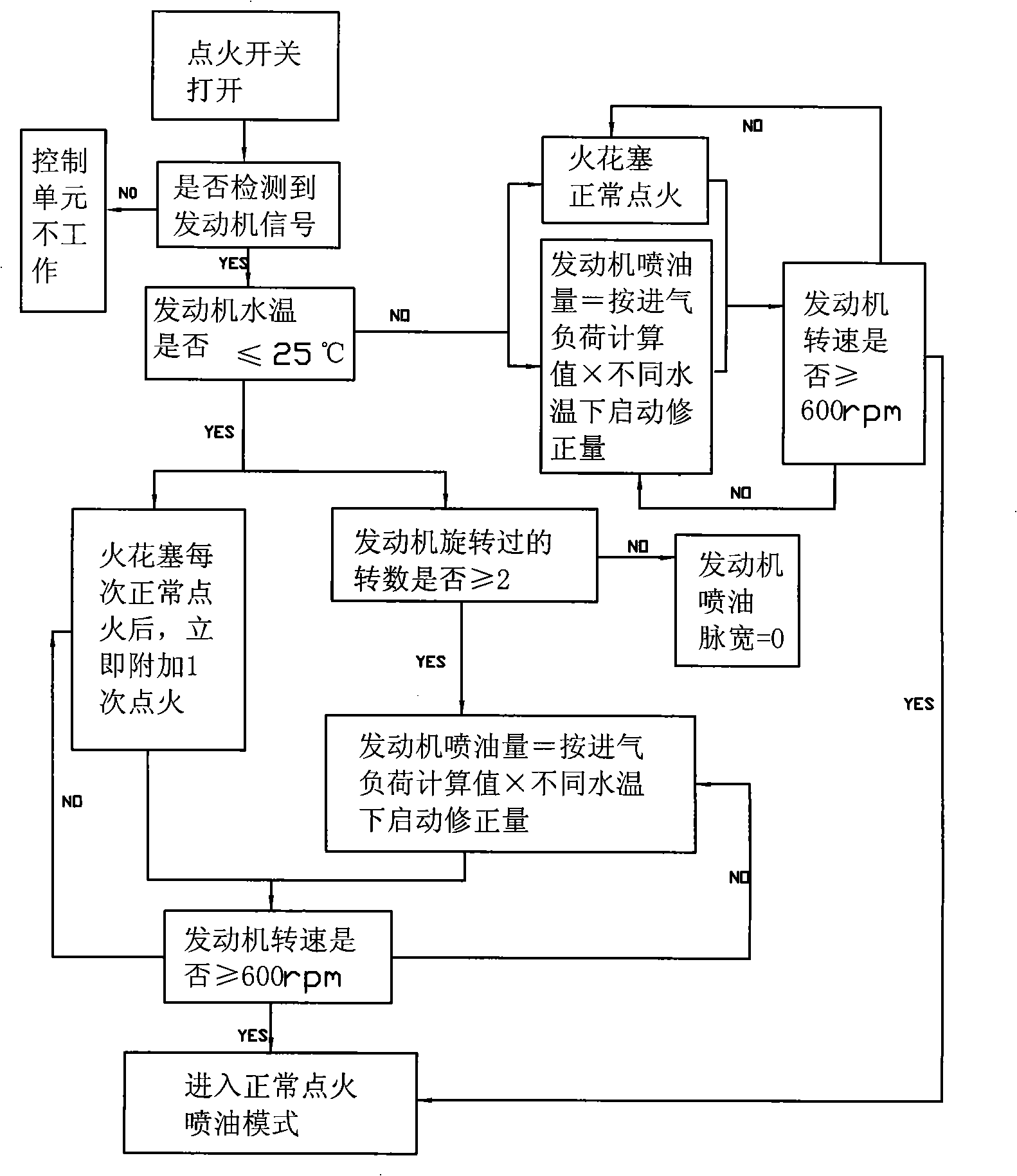

[0009] As shown in the figure, when the gasoline engine is started, the ignition lock switch is first turned on, and the control unit is powered on to start. After the control unit receives the engine speed signal, it judges whether the engine water temperature is below -25°C through the temperature sensor. The engine is set to different values. If the water temperature is lower than -25°C, the engine will start from the time when the engine speed sensor detects the engine speed signal to 2 revolutions of the engine, but the control unit controls the injector to not inject fuel, but after idling for 2 revolutions ( This value can be calibrated, and different values are used for different engines), and the injection is controlled according to the product of the fuel injection quantity calculated by the intake load (the intake load is measured by the speed sensor and pressure sensor) and the starting correction value under different water temperatures. Oil nozzle injection, thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com