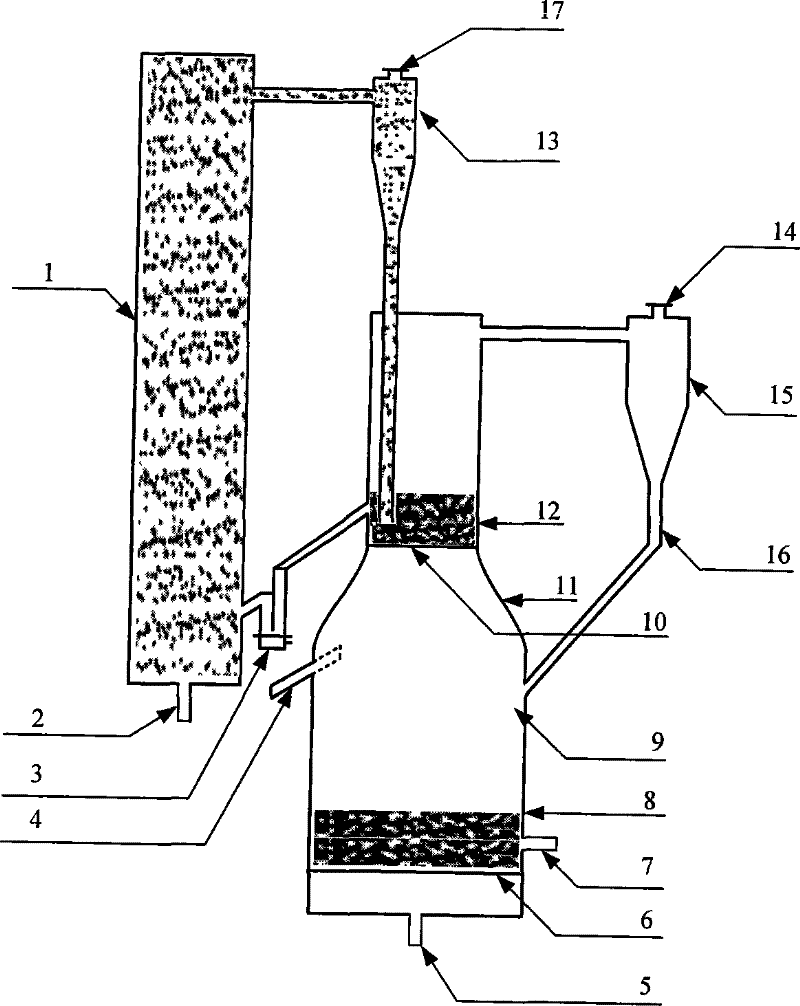

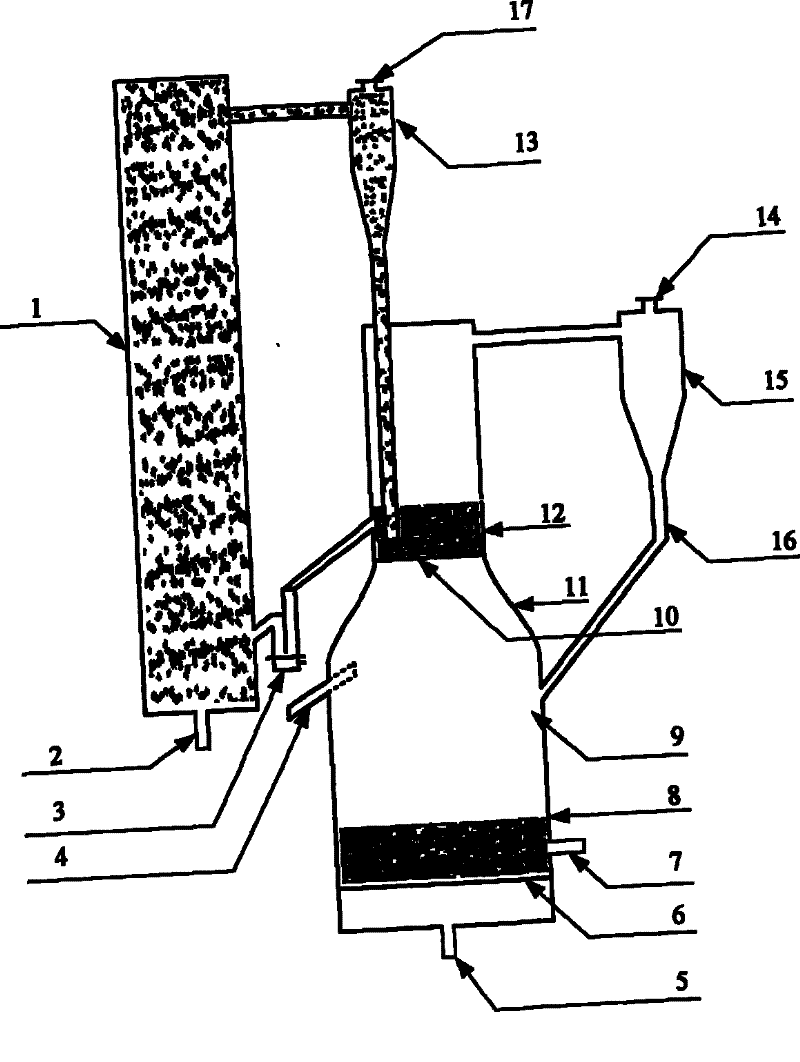

Double distribution plate coal-base serial fluidized-bed chemical chain combustion apparatus

A technology of chemical looping combustion and fluidized bed, which is applied in the field of double distribution plate coal-based serial fluidized bed chemical looping combustion device, can solve the problems of increased investment costs and difficult operation, and achieve rapid response, flexible operation, and wide The effect of industrial application value and social application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The main structure of this embodiment includes a circulating fluidized bed 1, an air inlet 2, a first cyclone separator 13, a material return device 3, a bubbling fluidized bed 9, an air inlet 5, a feed inlet 7, a distribution plate 6, Distribution plate 10, low gas velocity gasification zone 8, transition zone 11, high gas velocity reduction zone 12, inclined jet pipe 4, second cyclone separator 15, cyclone separator exhaust port 14 and dip leg 16; The chemical bed 1, the first cyclone separator 13, the material return device 3, the low gas velocity gasification zone 8, the transition part 11, the high gas velocity reduction zone 12 and the second cyclone separator 15 are connected to form a circulation loop; The upper part of the fluidized bed 1 is communicated with the upper part of the first cyclone separator 13, the lower part of the first cyclone separator 13 is communicated with the high gas velocity reduction area 12, and the high gas velocity reduction area 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com