Ring heating stove possessing partition air curtain device

A ring-shaped heating furnace and heating furnace technology, applied in lighting and heating equipment, furnace, furnace type and other directions, can solve the problems of difficult furnace pressure control, waste of fuel, furnace door spewing fire, etc., to achieve convenient adjustment and control and save energy consumption , the effect of energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

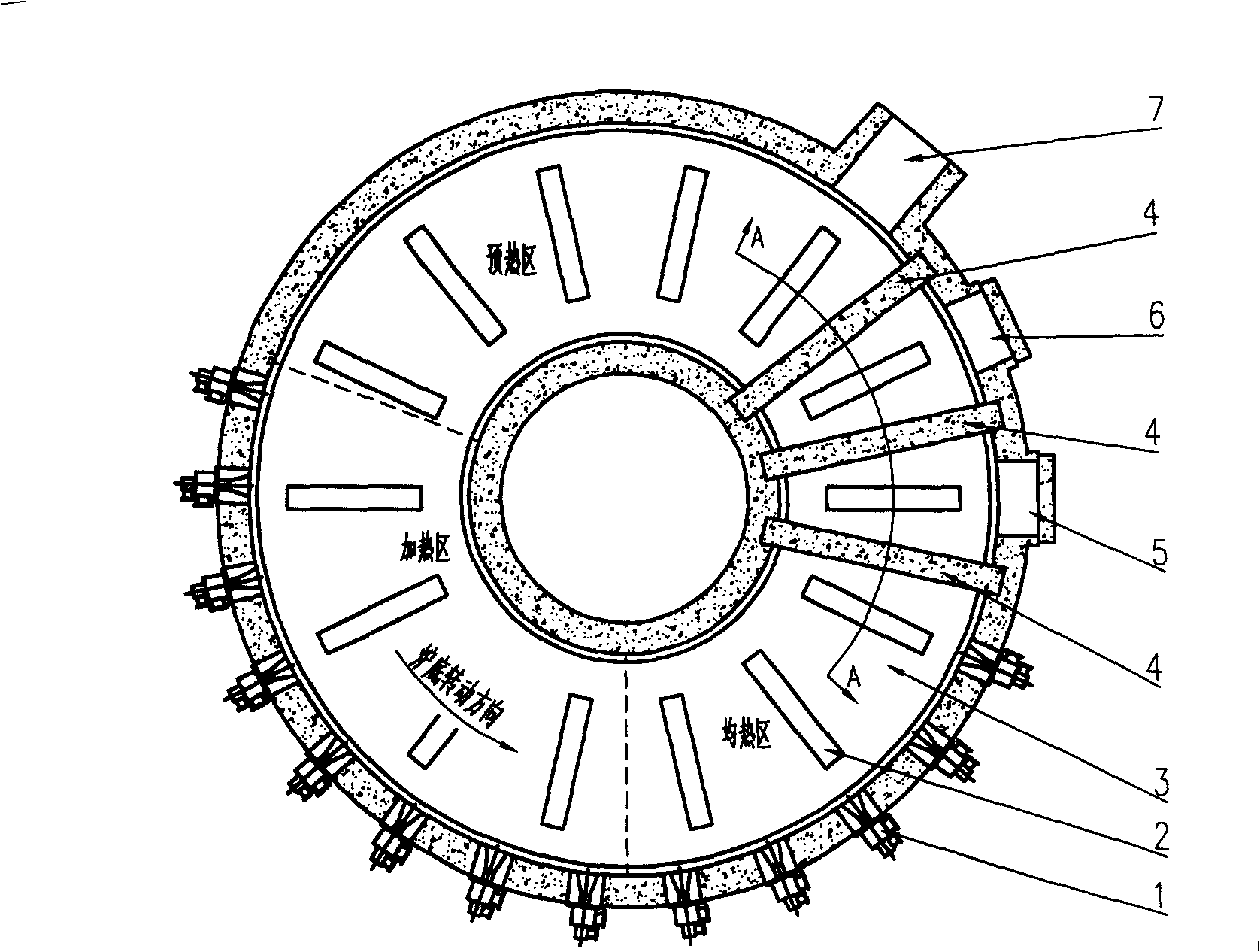

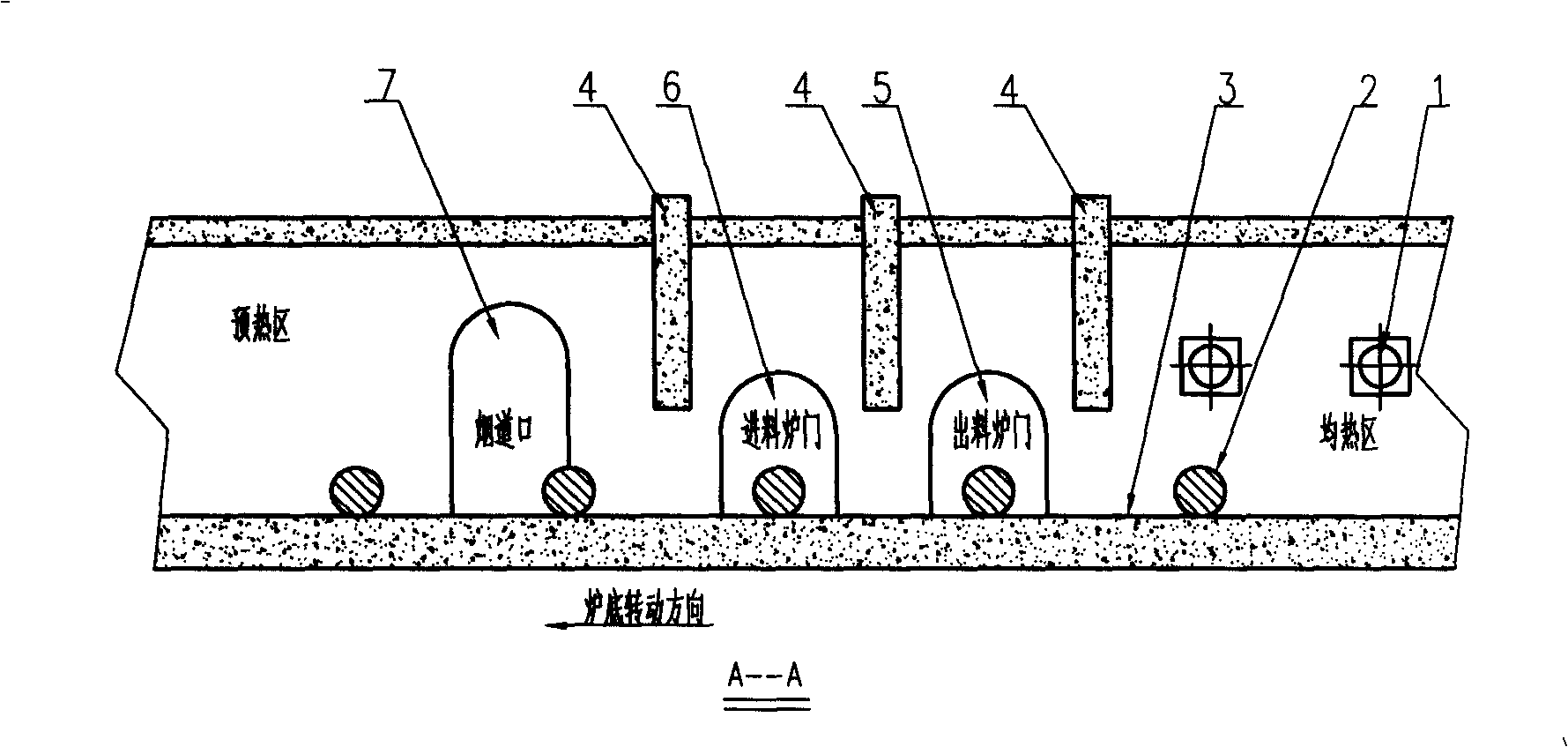

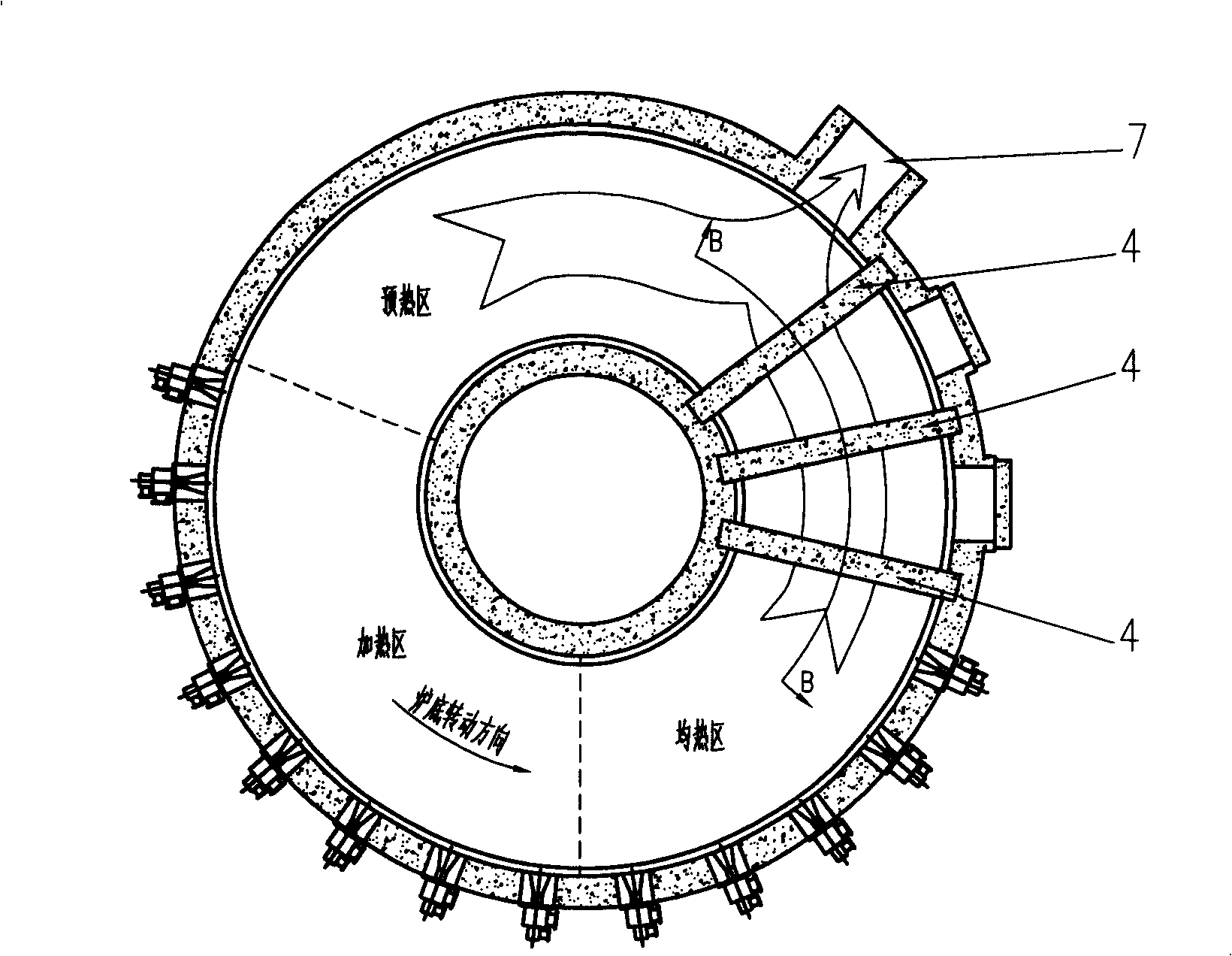

[0026] Such as Figure 5 ~ Figure 6 Shown: including burner combustion system 1, billet 2, furnace bottom 3, choke partition wall 4-1, choke partition wall 4-2, choke partition wall 4-3, discharge furnace door 5, feed furnace Door 6, smoke outlet 7, curtain pipe 8, air curtain device 9, regulating valve 10 and ring furnace body 11.

[0027] The invention mainly consists of a ring furnace body and a rotary furnace bottom. The annular furnace body is divided into a preheating zone, a heating zone and a soaking zone. The burner combustion system 1, the heating furnace smoke outlet 7, the discharge furnace door 5, and the feed furnace door 6 are arranged on the ring furnace body 11, and the front, rear and middle of the feed furnace door 6 and the discharge furnace door 5 are arranged. Three choke partition walls 4-1, 4-2, 4-3 are set. The lower edge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com