Gas spring environmental simulated fatigue-testing machine

A fatigue testing machine and environmental simulation technology, applied in the field of gas spring environmental simulation fatigue testing machine, can solve the problems of long heating and cooling time, affecting service life, high energy consumption, and achieving small box volume, good sealing effect, and cooling energy. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

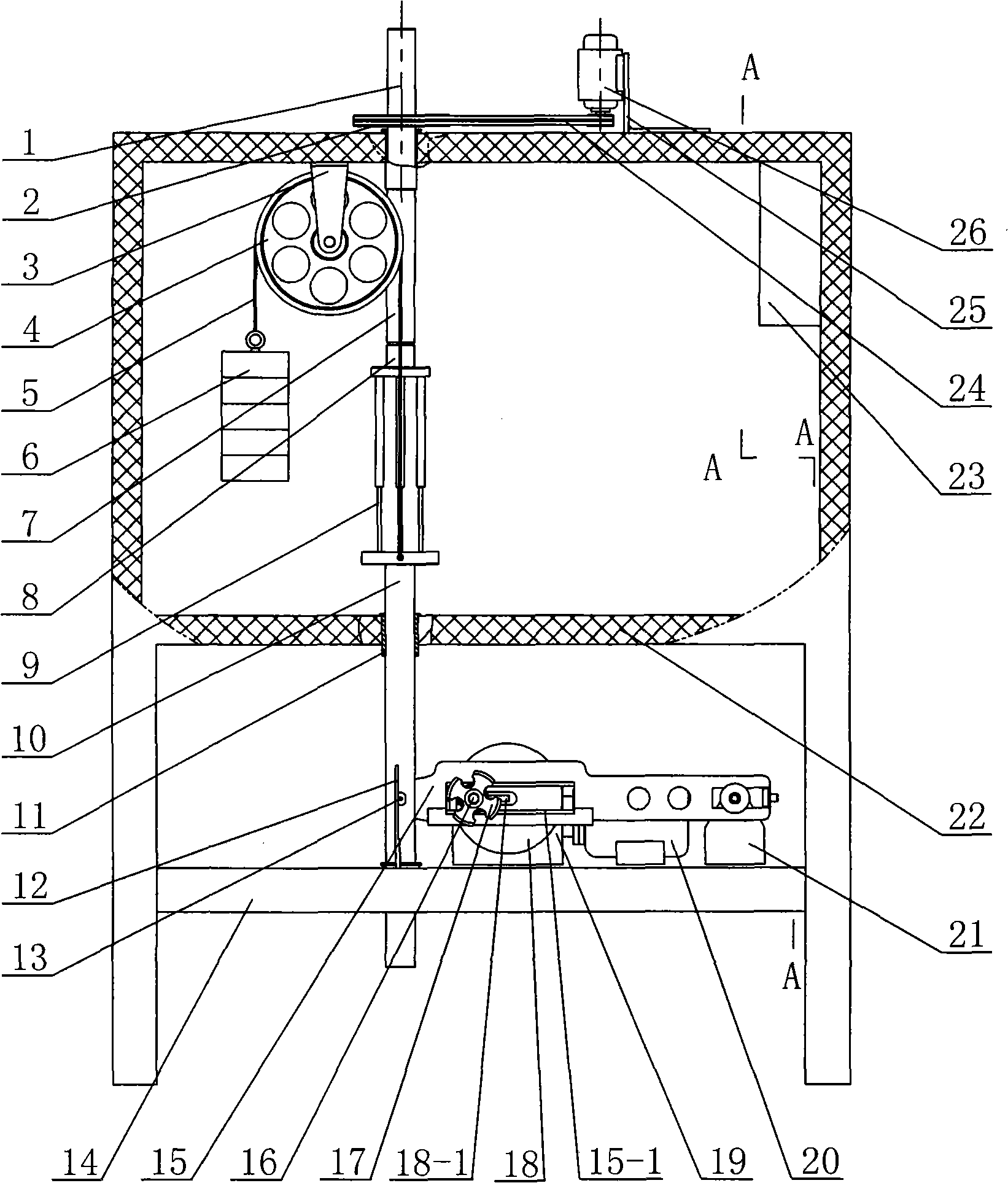

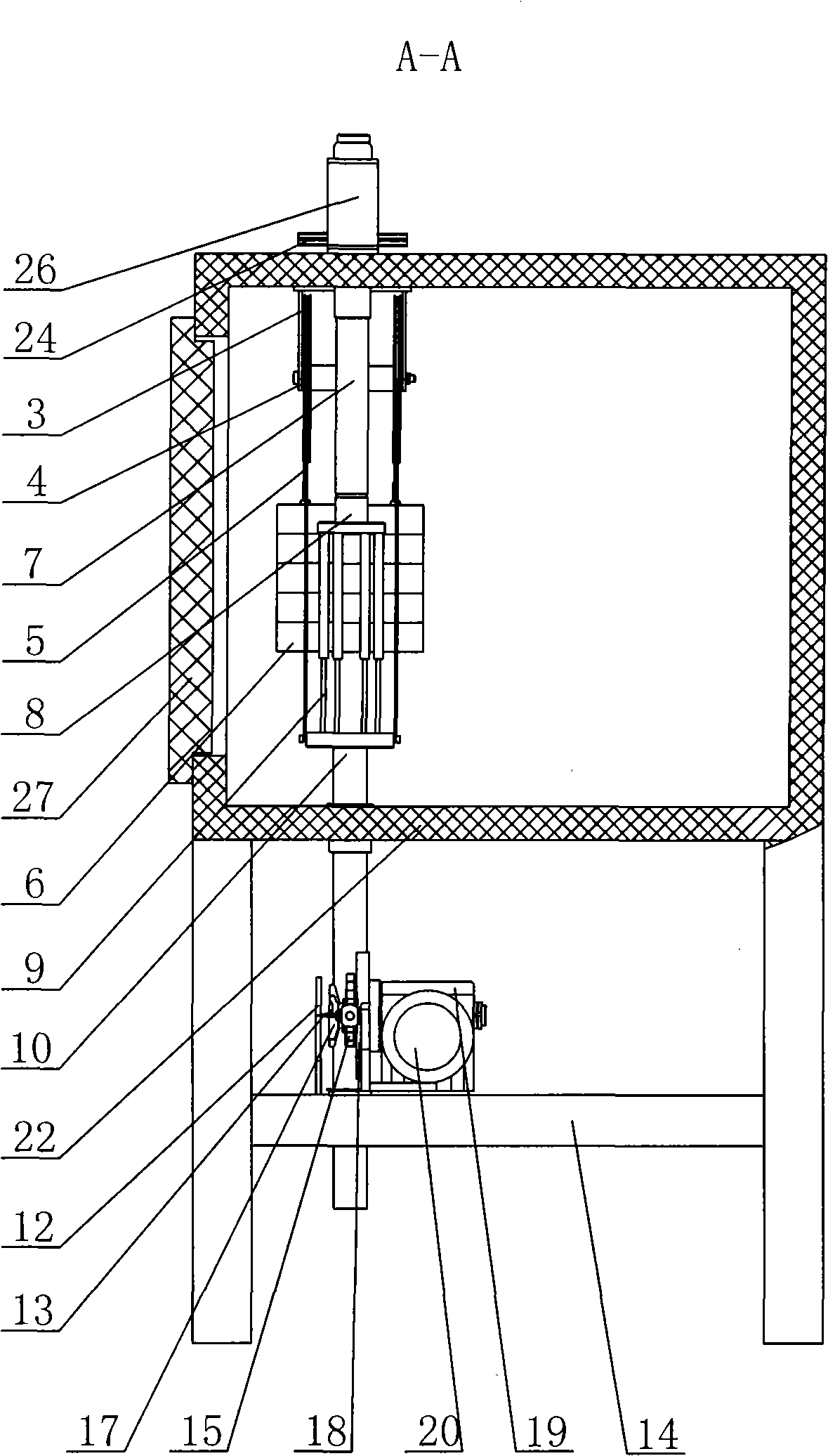

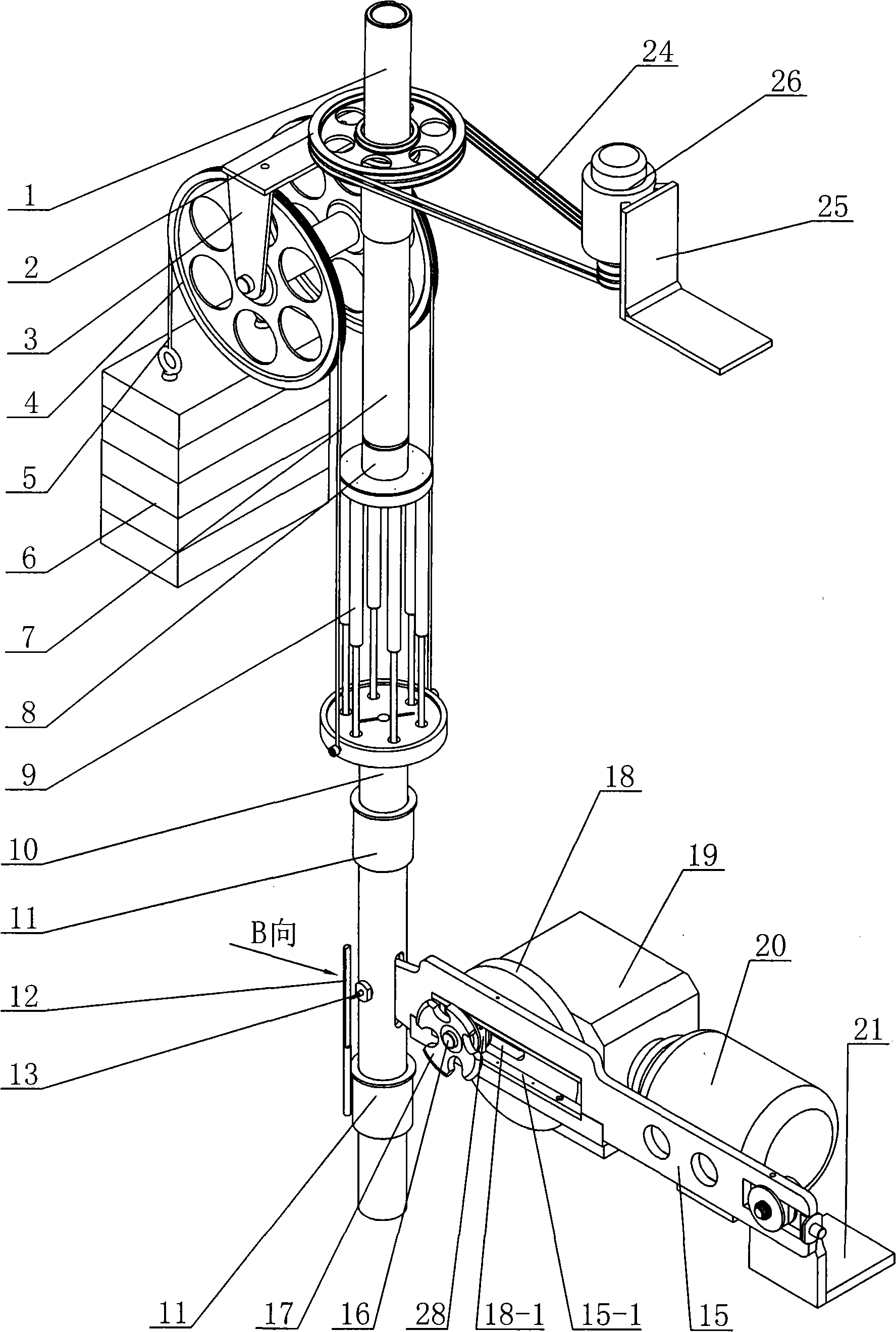

[0015] See Figure 1~3 As shown, the gas spring environmental simulation fatigue testing machine of the present invention includes a frame 14 , a box assembly, a mechanical transmission device, a counterweight device, a hanging plate 8 and a transmission shaft 10 . See figure 1 Shown, the box body assembly of the present invention is made of the box body 22 of heat preservation and the box door 27 that is installed on the box body 22, and box body assembly is fixed on the frame 14, and heating and cooling device 23 is installed in the box body 22, or The heating and cooling device 23 is installed outside the box body 22, and the box body 22 has a vent, and the simulated ambient temperature of the gas spring under test in the box body 22 is controlled by controlling the heating and cooling device 23.

[0016] See Figure 1~3 As shown, the mechanical transmission device of the present invention is installed on the frame 14 and is positioned at the outside of the casing 22, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com