High-temperature thermodilatometer for measuring refractory materials large test sample and method of use thereof

A technology of refractory materials and thermal dilatometer, which is applied in the fields of thermal expansion coefficient of materials, instruments, and special data processing applications. The effect of convenient sample making and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A jack-type high-temperature thermal dilatometer for measuring large samples of refractory materials and a method for using the same. The adopted technical scheme has two aspects, one is the structure of the high-temperature thermal dilatometer for measuring large samples of refractory materials; the other is the use method of the high-temperature thermal dilatometer for measuring large samples of refractory materials.

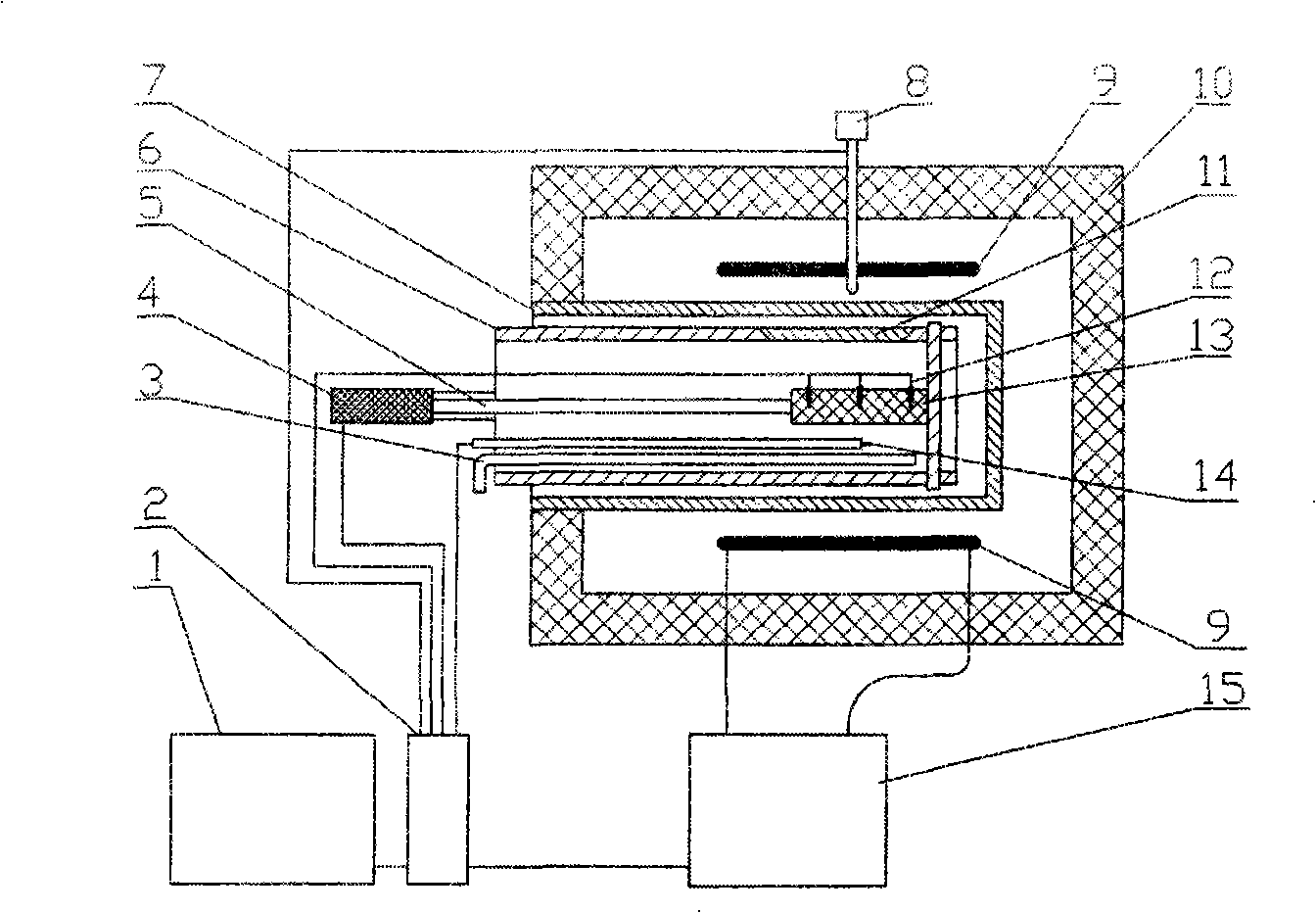

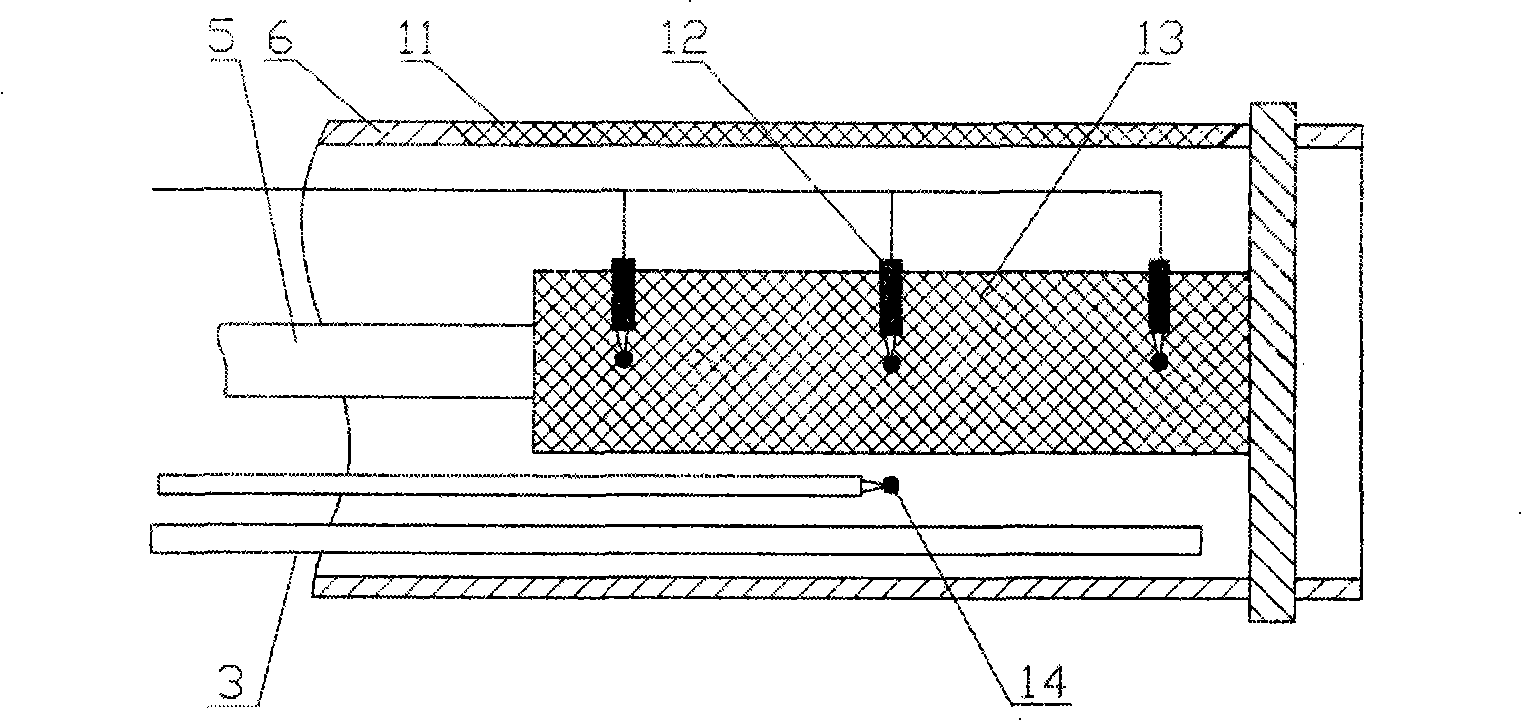

[0049] 1. The structure of the high-temperature thermal dilatometer for measuring large samples of refractory materials is as follows: figure 1 , figure 2As shown, the dilatometer is a horizontal structure. Its specific structure is: a silicon-molybdenum rod heating element 9 is arranged in the heating furnace body 10, the soaking zone length in the heating furnace body 10 is 200 mm to 500 mm, and a soaking corundum tube 7 is arranged on the inside of the heating element 9. The nozzle of the hot corundum tube 7 is set outside the furnace body 10, a t...

Embodiment 2

[0084] A jack-type high-temperature thermal dilatometer for measuring large samples of refractory materials and a method for using the same. The adopted technical scheme has two aspects, one is the structure of the high-temperature thermal dilatometer for measuring large samples of refractory materials; the other is the use method of the high-temperature thermal dilatometer for measuring large samples of refractory materials.

[0085] 1. The structure of the high-temperature dilatometer for measuring large samples of refractory materials is: figure 1 , figure 2 As shown: the heating element 9 is a silicon carbide rod, the protective gas input pipe 3 communicates with the gas source of the protective atmosphere, and 0.5 liters / min of nitrogen gas can be introduced into the soaking corundum tube 7 through the protective gas input pipe 3 . Others are with embodiment 1.

[0086] 2. The method of using the high-temperature thermal dilatometer for measuring large samples of refra...

Embodiment 3

[0094] A jack-type high-temperature thermal dilatometer for measuring large samples of refractory materials and a method for using the same. The adopted technical scheme has two aspects, one is the structure of the high-temperature thermal dilatometer for measuring large samples of refractory materials; the other is the use method of the high-temperature thermal dilatometer for measuring large samples of refractory materials.

[0095] 1. The structure of the high-temperature dilatometer for measuring large samples of refractory materials is the same as in Example 2.

[0096] 2. The steps to use the high-temperature thermal dilatometer for measuring large samples of refractory materials are:

[0097] The first step: the steps of loading the sample (13) into the heating furnace body (10) are the same as in Example 1.

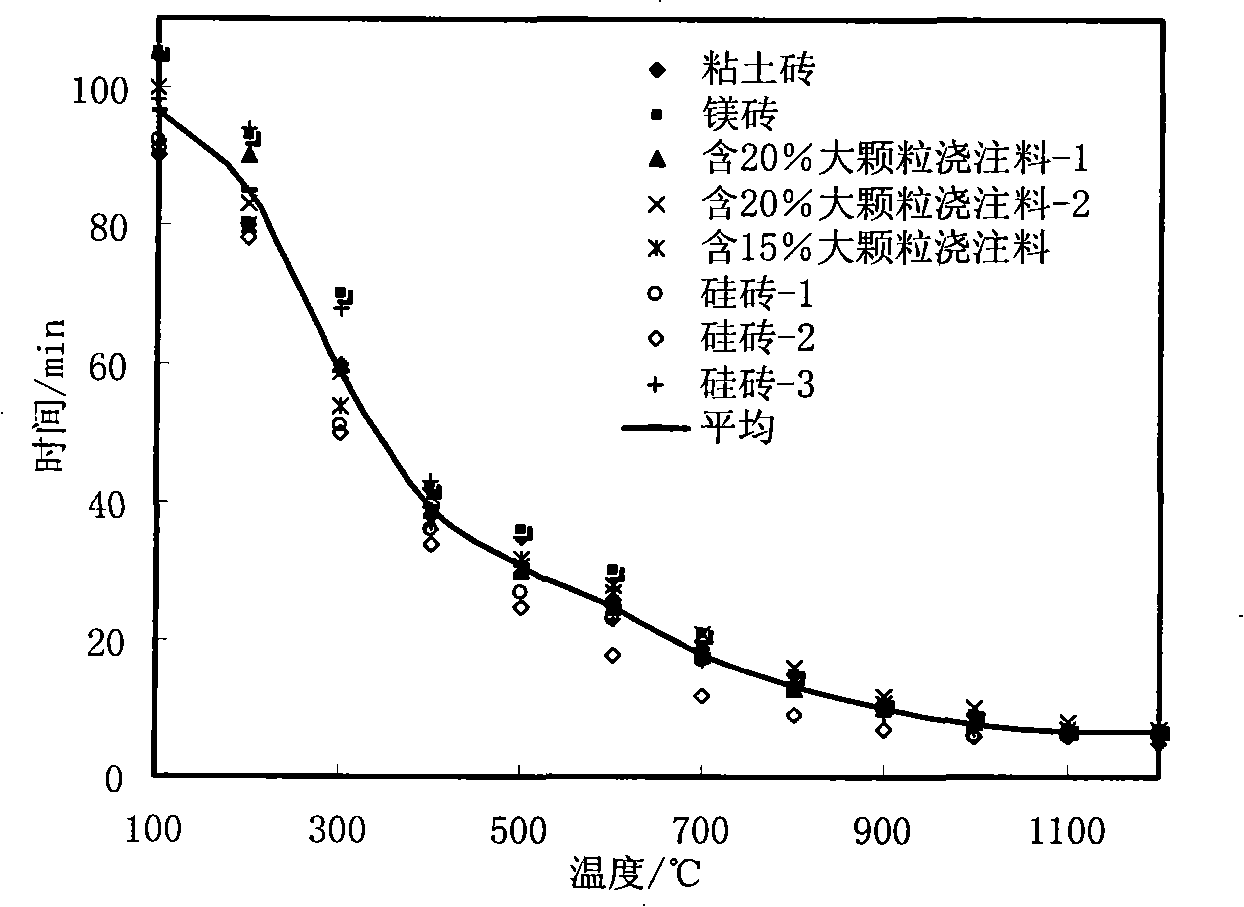

[0098]Step 2: According to the high-temperature thermal dilatometer measurement program, measure and record the time for the sample 13 of the specified material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com