Array type microresonant cavity tunable integrated optical filter

An optical filter and micro-resonator technology, applied in the field of optical filters, can solve the problems of high cost, inefficiency, difficulty, etc., and achieve the effects of narrow passband width, high transmittance, and reduced process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

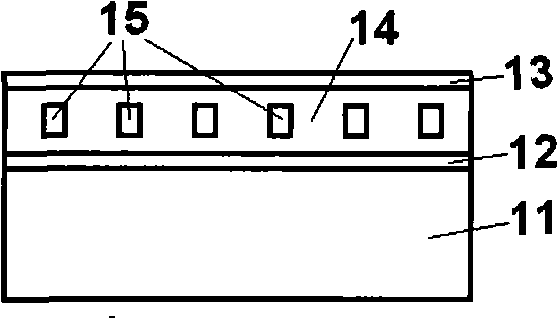

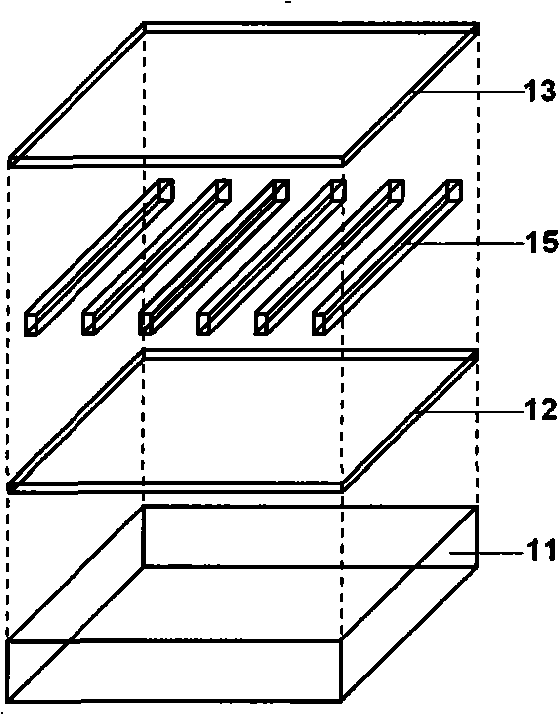

[0024] Figure 1~2 A schematic diagram of Embodiment 1 of the unit structure of an array microresonator tunable integrated optical filter is given. The structure is provided with a substrate 11, and a lower metal film 12 is arranged on the substrate 11. On the lower metal film 12, there is a dielectric layer 14 in which a one-dimensional metal grating 15 is embedded. On the dielectric layer 14, there is an upper metal film. 13. Substrate 11 can be selected as transparent dielectric substrate or semiconductor substrate (semiconductor substrate wherein can be the semiconductor chip that has made optoelectronic device); Lower layer metal film 12, upper layer metal film 13 and metal grating layer 15 can be selected as gold , silver, copper and aluminum and other good conductor metal materials; the dielectric layer 14 can be selected from high transmitta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com