Potato fibres, methods of preparing them and their use

A potato fiber, potato technology, applied in the direction of food preparation, application, food science, etc., to achieve the effect of low ash content, improved quality, and reduced possibility of allergenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

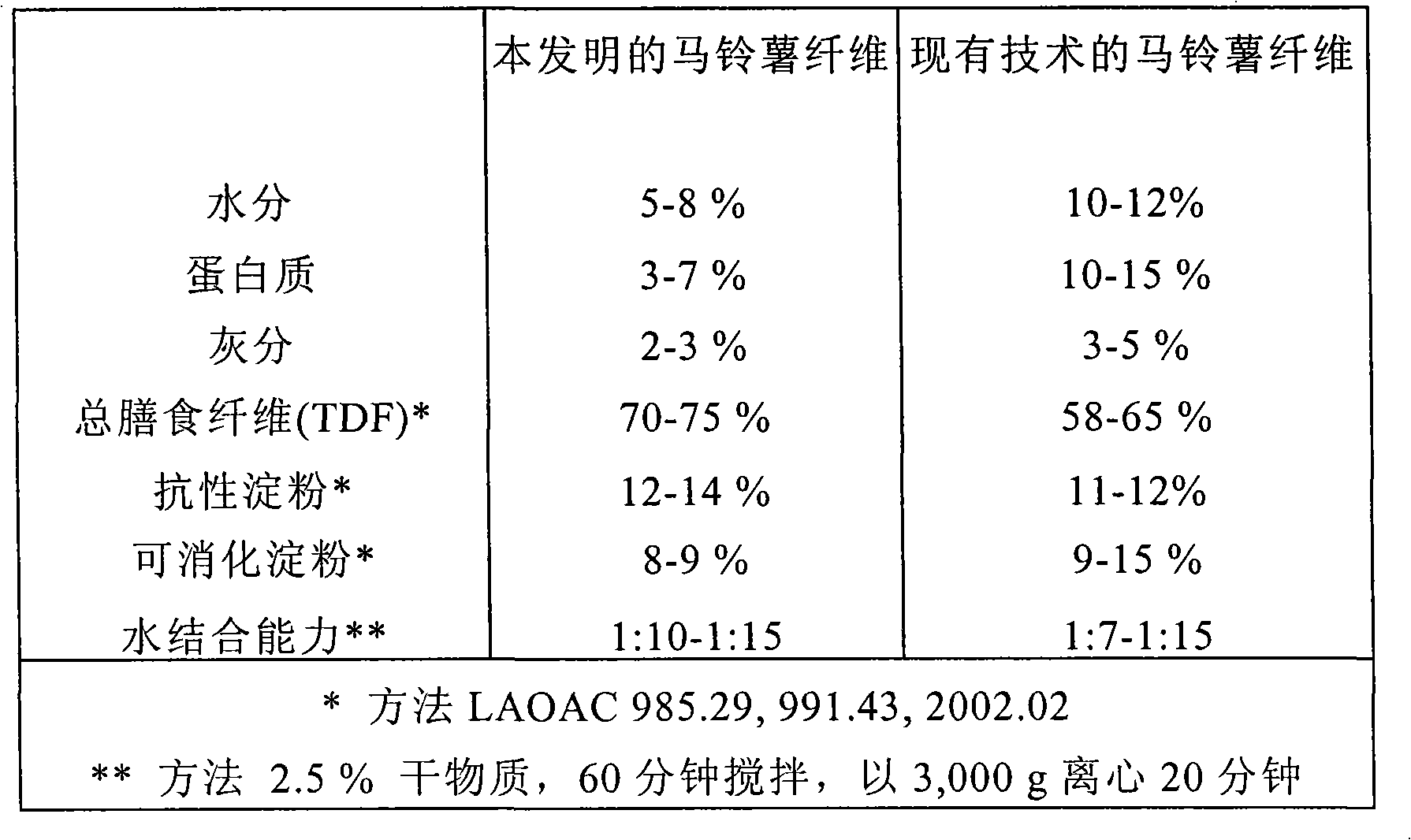

AI Technical Summary

Problems solved by technology

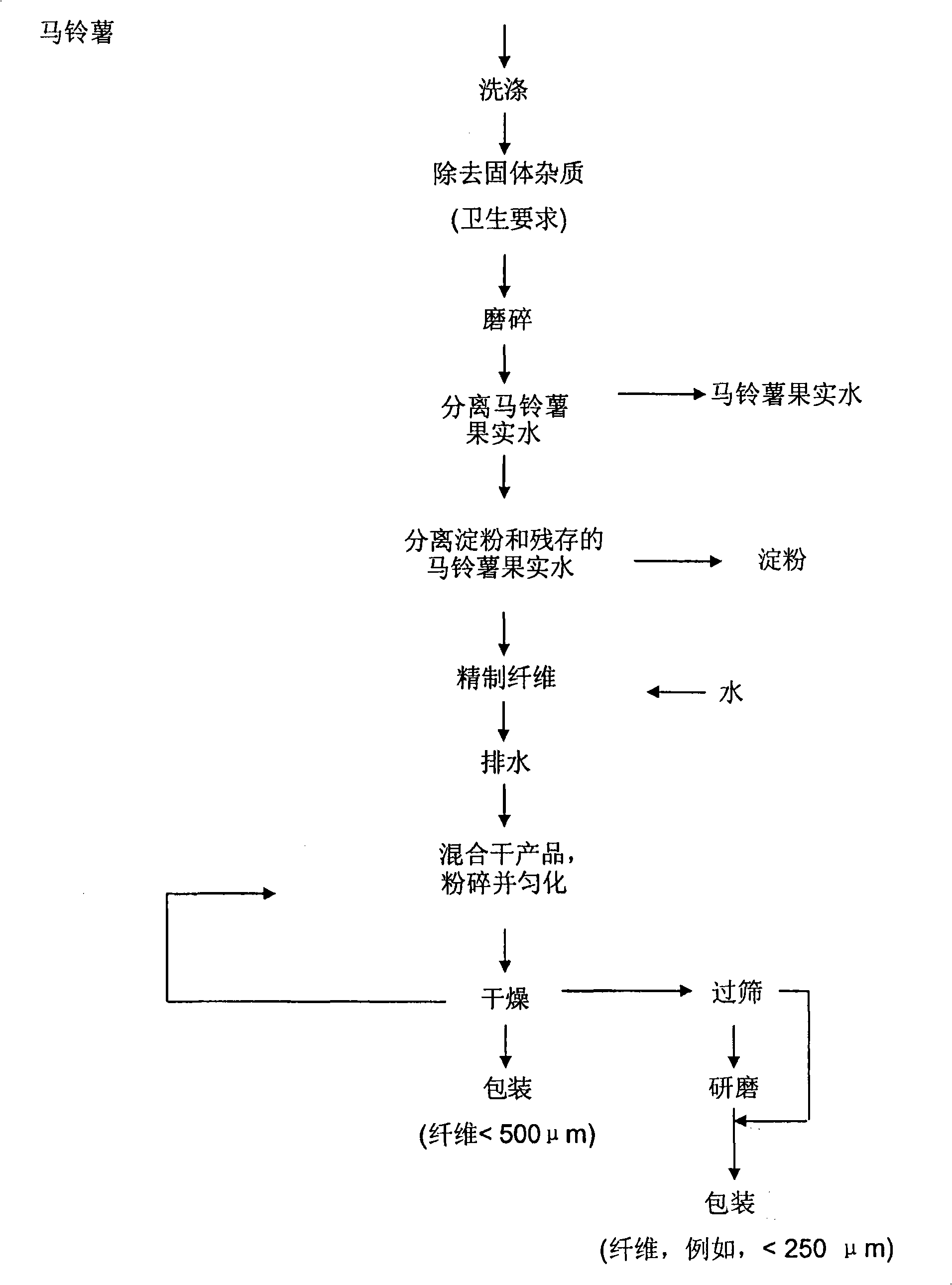

Method used

Image

Examples

Embodiment 1

[0033] Example 1 (wide noodles ("ribbon noodles"))

[0034] 420g durum wheat flour

[0035] 280g water

[0036] 22g potato fiber

[0037] 8g salt

[0038] 730g

[0039] produce:

[0040] First, put all the ingredients in a bowl and mix together for 2 minutes. The mixture is then kneaded at a higher speed into a compact dough that is no longer moist and no longer sticky. The dough is shaped into a ball, covered with a food film, and allowed to stand for 1 hour. Then, the dough is rolled into thin slices on a slightly floured surface and fed into the macaroni machine. Now cut into lasagna and hang until slightly dry or whitish, neat and then freeze.

[0041] For the produced lasagna, the advantages of the potato fiber of the present invention are obvious. Lasagna maintains a high content of coarse fiber food, which produces health benefits. In addition, the higher water binding capacity of the pasta means that less material must be used.

Embodiment 2

[0042] Example 2 (bread roll)

[0043] 1,010g wheat flour 550 type

[0044] 655g water

[0045] 50g yeast

[0046] 44g potato fiber

[0047] 20g table salt

[0048] 10g monoglycerides and diglycerides of food fatty acids

[0049] 9g sugar

[0050] 730g

[0051] produce:

[0052] Dissolve the yeast in some water. Then, put the dry ingredients in a bowl and mix them with a dough hook for 2 minutes, and then process them into a viscous dough at a medium speed. Let the dough rise for 10 minutes. Form the dough into a blank, let them sit for 20 minutes, and then squeeze out air bubbles. First fermented in a combined steamer at 35°C and 75% air humidity for 30 minutes, and then baked at 180°C and 60% humidity for 13 minutes. Finally, with the lid open, bake at 190°C for 5 minutes.

[0053] The use of the potato fiber of the present invention in the production of dough rolls resulted in a 2.6% reduction in baking loss. In addition, more water is incorporated in the baked product, ...

Embodiment 3

[0054] Example 3 (Hamburg)

[0055] Ingredients for about 11 burgers each weighing 70g:

[0056] 533.5g lean beef (loin)

[0057] 160g pork belly (lard)

[0058] 10g salt

[0059] 0.5g ground black pepper

[0060] 24g potato fiber

[0061] 72g water

[0062] 800g

[0063] preparation:

[0064] Cut the beef and pork belly through the 5mm plate of the pulverizer. Add the mixed spices and salt and mix well. The meat mixture was formed into round hamburger patties and toasted at 150°C in a convectomat.

[0065] When the potato fiber of the present invention is used to make burgers, the fat and water-binding capacity is advantageously improved; when, for example, more than 3% by weight of potato fiber is used, escape of water is no longer observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com