Device and method for conserving anaerobic particle sludge in beer industrial waste water treatment

A technology for anaerobic granular sludge and industrial wastewater, which is applied in the treatment of food industry wastewater and anaerobic digestion treatment. , the problem of high mortality of anaerobic granular activated sludge, to achieve the effect of flexible use, small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

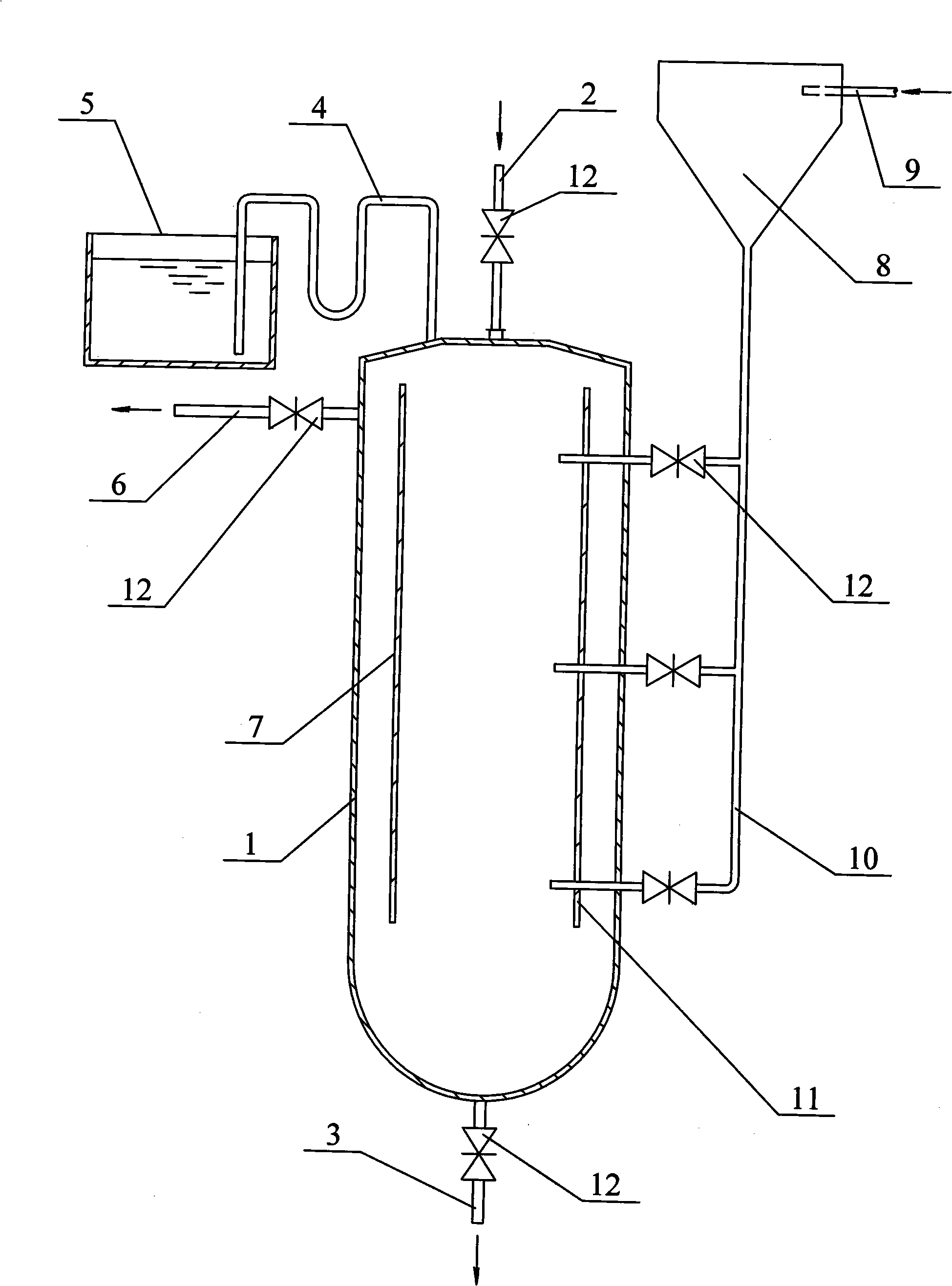

[0012] Specific implementation mode one: (see figure 1 ) The storage device for anaerobic granular sludge in the beer industry wastewater treatment in this embodiment is made of corrosion-resistant FRP and PVC, and is composed of a tank 1, a mud inlet pipe 2, a mud outlet pipe 3, an air outlet pipe 4, and a water sealing device 5 , liquid outlet pipe 6, liquid inlet funnel 8, the first liquid inlet pipe 9 and the second liquid inlet pipe 10; The air port communicates with the air inlet of the air outlet pipe 4, the air outlet of the air outlet pipe 4 extends into the bottom of the water seal device 5, the liquid outlet on the top of the tank 1 communicates with the liquid inlet of the liquid outlet pipe 6, and the mud outlet at the bottom of the tank 1 The mouth is communicated with the mud inlet of the mud outlet pipe 3, the liquid outlet of the first liquid inlet pipe 9 is communicated with the liquid inlet on the upper part of the liquid inlet funnel 8, and the liquid outle...

specific Embodiment approach 2

[0014] Specific implementation mode two: (see figure 1 ) The difference between this embodiment and the specific embodiment one is: the first partition 7 and the second partition 11 are also arranged in the tank 1 of the storage device for anaerobic granular sludge in the treatment of beer industry wastewater, and the first partition 7 and the two sides of the second partition 11 are fixedly connected with the inner wall of the tank 1 respectively, and the second liquid inlet pipe 10 extends into the inside of the tank 1 through the second partition 11 from the upper, middle and lower parts of the tank 1 respectively. Others are the same as in the first embodiment.

[0015] A baffle is added in the tank 1 to increase the turbulence of the water flow without creating a dead zone, and to form a good sedimentation zone to help the water get rid of too much granular sludge.

specific Embodiment approach 3

[0016] Specific embodiment three: the preservation method of anaerobic granular sludge in the beer industry wastewater treatment in this embodiment is realized by the following steps: one, anaerobic granular sludge is stored in the anaerobic granular sludge in the brewery wastewater treatment process In the storage device, adjust the pH value of the nutrient solution to 6.8-7.5 and then pass it into the anaerobic granular sludge storage device. The total amount of culture solution is 2.5-4.5% of the sludge volume.

[0017] In this embodiment, the gas and supernatant in the container are exported at any time during the preservation process. Anaerobic granular sludge refers to the remaining sludge that grows and reproduces in the process of brewery wastewater treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com