Draught fan

A technology for induced draft fans and fans, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of putting into use, unattainable noise pollution, increasing noise pollution, etc., reducing noise and friction. , The effect of avoiding industrial noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention is described below:

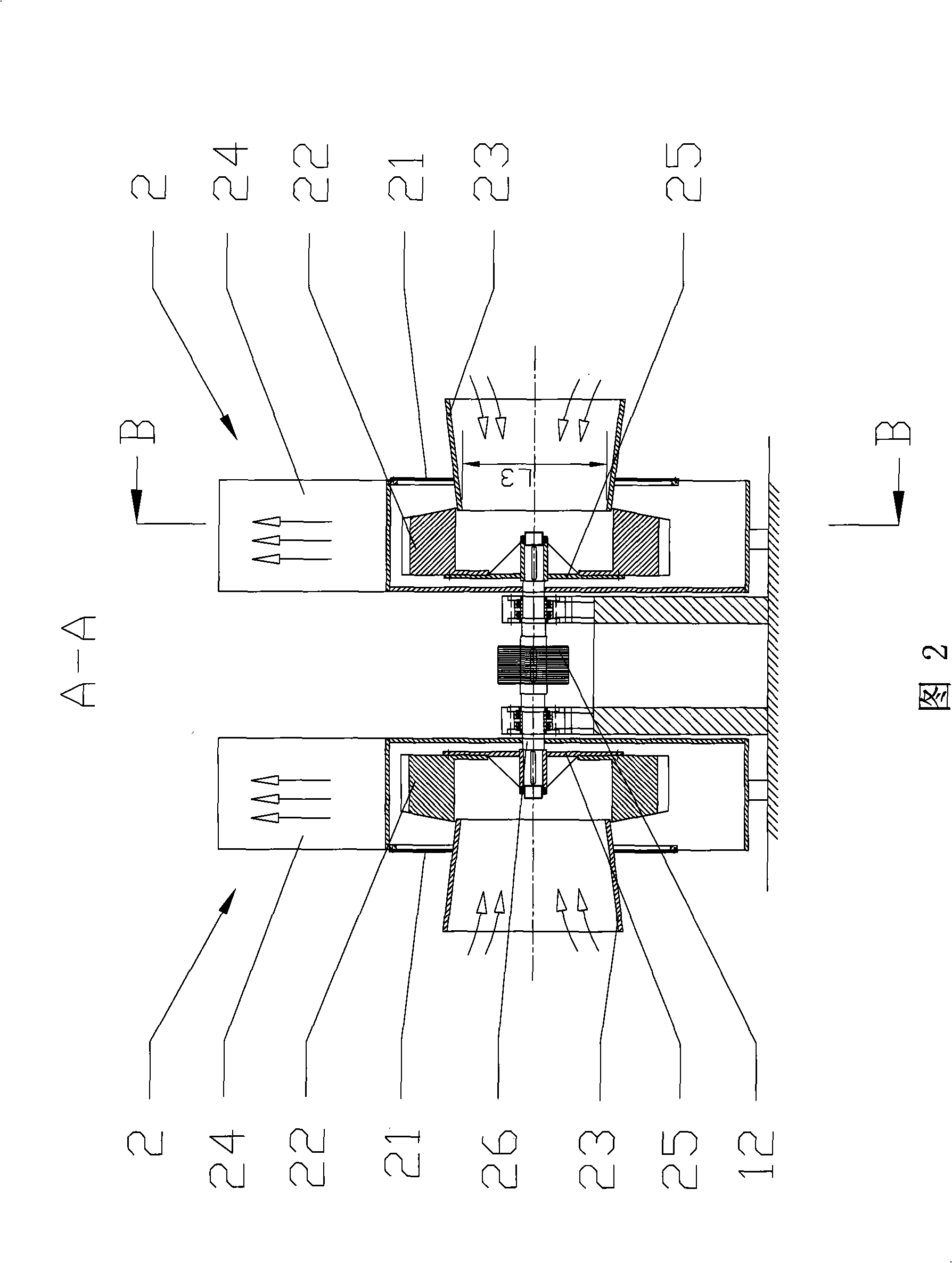

[0017] As shown in FIG. 2 , an induced draft fan according to the present invention includes a pair of fan main bodies 2 arranged symmetrically on both sides of a motor 11 . Each fan main body 2 includes a fan casing 21 and a group of impellers 22 arranged in the fan casing 21 . The two sets of impellers 22 in the pair of blower main bodies 2 are respectively mounted on the two ends of the horizontal double-headed main shaft 26 , so that they can be driven by the motor 1 to rotate around the shaft in interlocking manner.

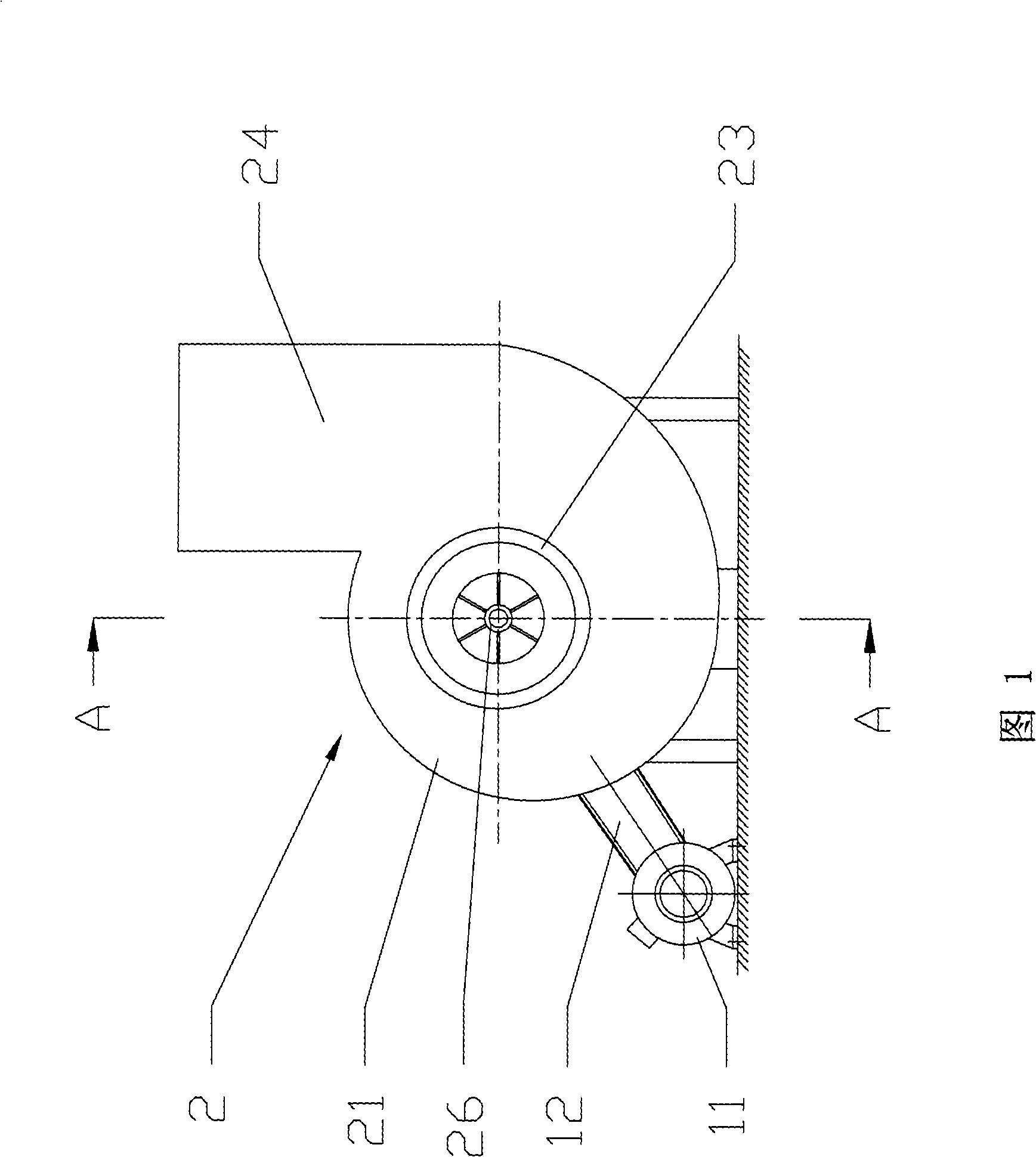

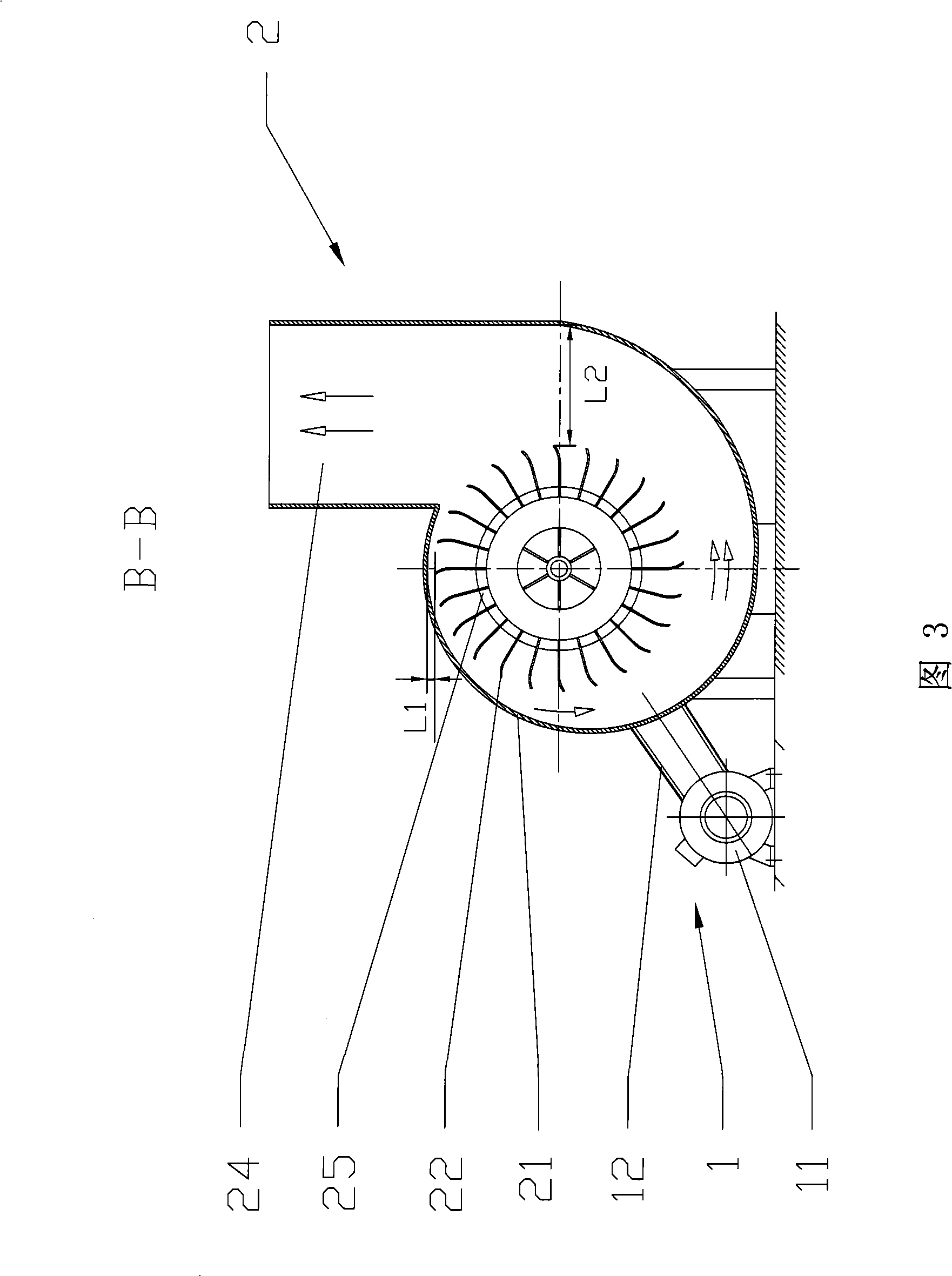

[0018] As shown in FIG. 1 , the cross-sectional shape of the fan housing 21 perpendicular to the axial direction is a logarithmic spiral.

[0019] As shown in accompanying drawings 1 and 2 , on one side of the fan housing 21 , a trumpet-shaped air inlet pipe 23 is provided coaxially with the impeller 22 . On the cylindrical side wall of the fan casing 21 , an air outlet pipe 24 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com