Two-stroke large diesel engine

A two-stroke, diesel engine technology, applied in mechanical equipment, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

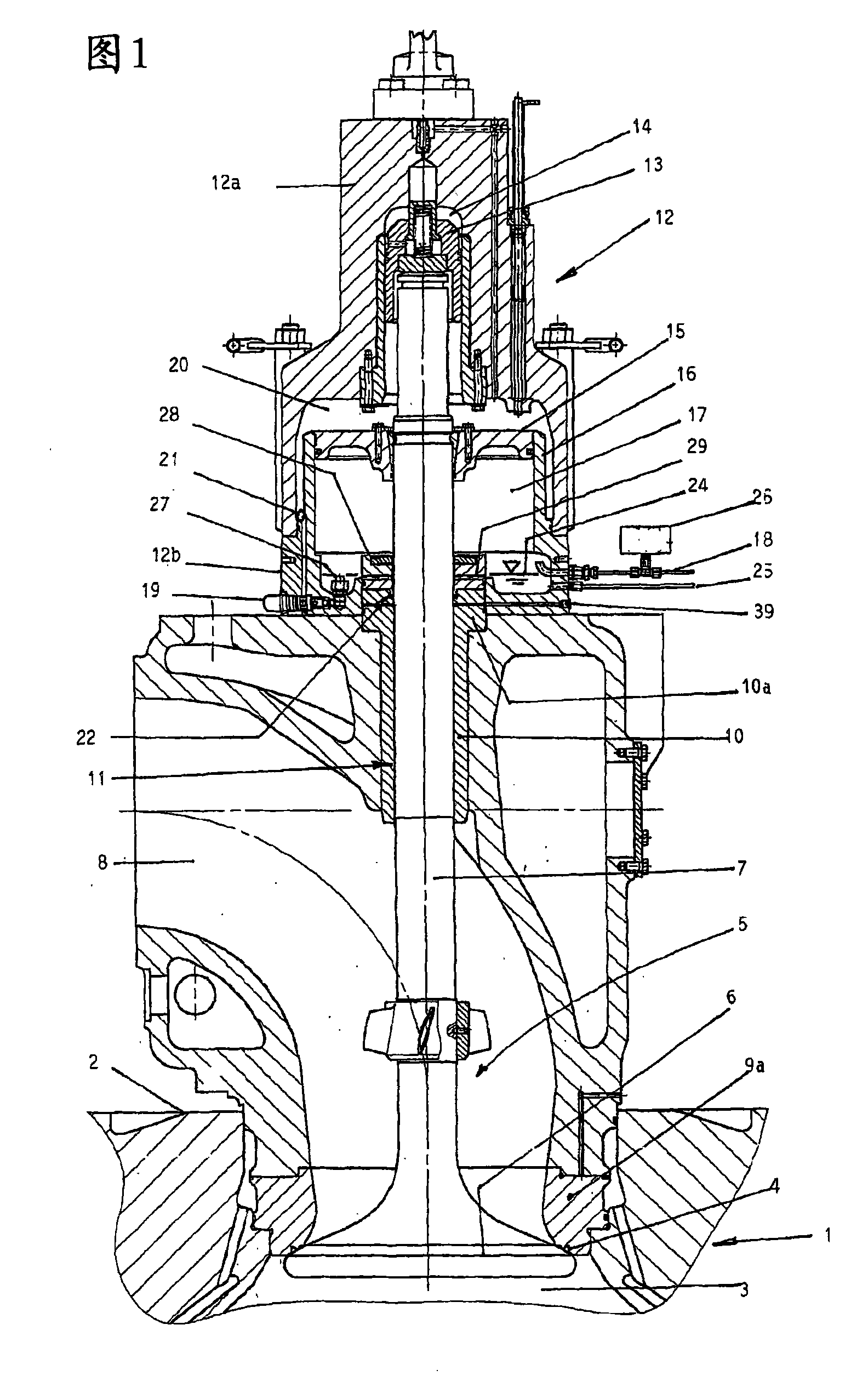

[0028] The exhaust valve 5 has a valve disk 6 that works together with the valve seat set in the 4 area of the exhaust port. It is installed on the lower end of a main shaft valve lever 7.Connecting the exhaust channel 8 with the exhaust port, the exhaust channel is open to the combustion room 3 when the seat is provided from the seat with the exhaust valve.Configure a set of exhaust valve shell 9 installed on the cylinder head 2 for the exhaust valve 5. The exhaust valve shell includes the exhaust channel 8.Install a circular circle 9A that is embedded in the cylinder head 2, including a valve seat with a limited exhaust port 4.In addition, the valve cover 9 also includes a guide cover 10 of the rod 7 of the exhaust valve 5.The guide cover and exhaust port 4 are set up and extended from the wall area of the upper part of the exhaust channel 8 from the upper wall of the valve case to the upper area of the valve case.Guide sleeve 10 pass through the wall area of the exhaust channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com