Method for preparing three-component coprecipitation molybdate antimicrobial by using microwave heating

A technology of microwave heating and antibacterial agent, applied in the direction of botany equipment and method, chemical instrument and method, application, etc., can solve the problems of ceramic surface color distortion, poor durability, and reduced antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

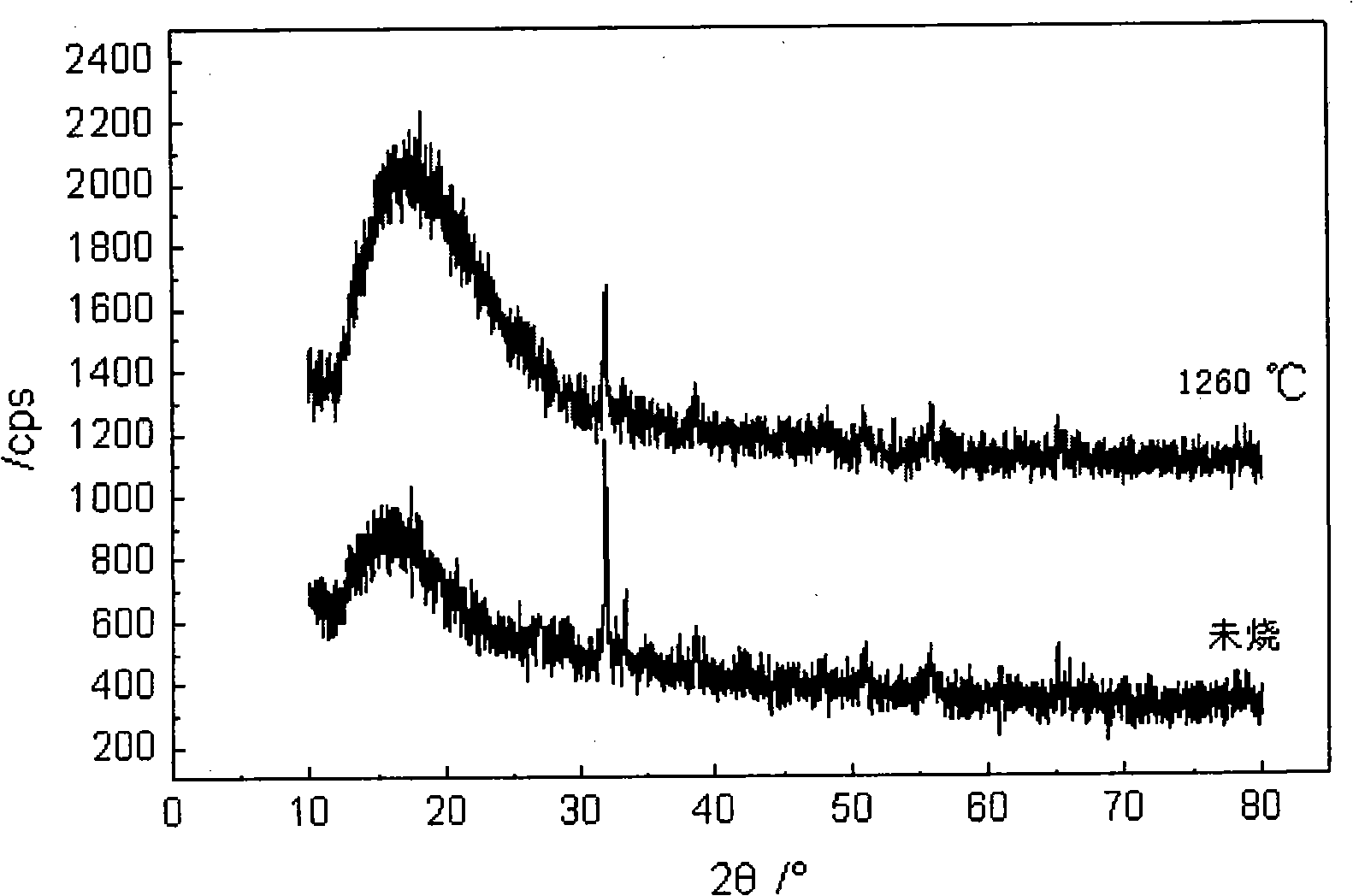

Method used

Image

Examples

Embodiment 1

[0035] Add 10ml of copper nitrate solution with a concentration of 0.1mol / L, 10ml of zinc nitrate solution with a concentration of 0.1mol / L and 40ml of silver nitrate solution with a concentration of 0.1mol / L to 50ml of sodium molybdate with a concentration of 0.1mol / L at the same time solution, a mixed solution was obtained. Stir the mixed solution for about 1 hour to make it evenly mixed. Then put it in a microwave oven with a power of 500-900W, heat it for 30-120s to complete the chemical reaction under microwave conditions, then take it out, and then stir the solution for about 1 hour, let it cool down during the stirring and wait for the precipitate to precipitate. Wash, filter, and dry the precipitated precipitate to obtain Ag 2 MoO 4 -ZnMoO4 -CuMoO 4 Three-component antimicrobial powder.

Embodiment 2

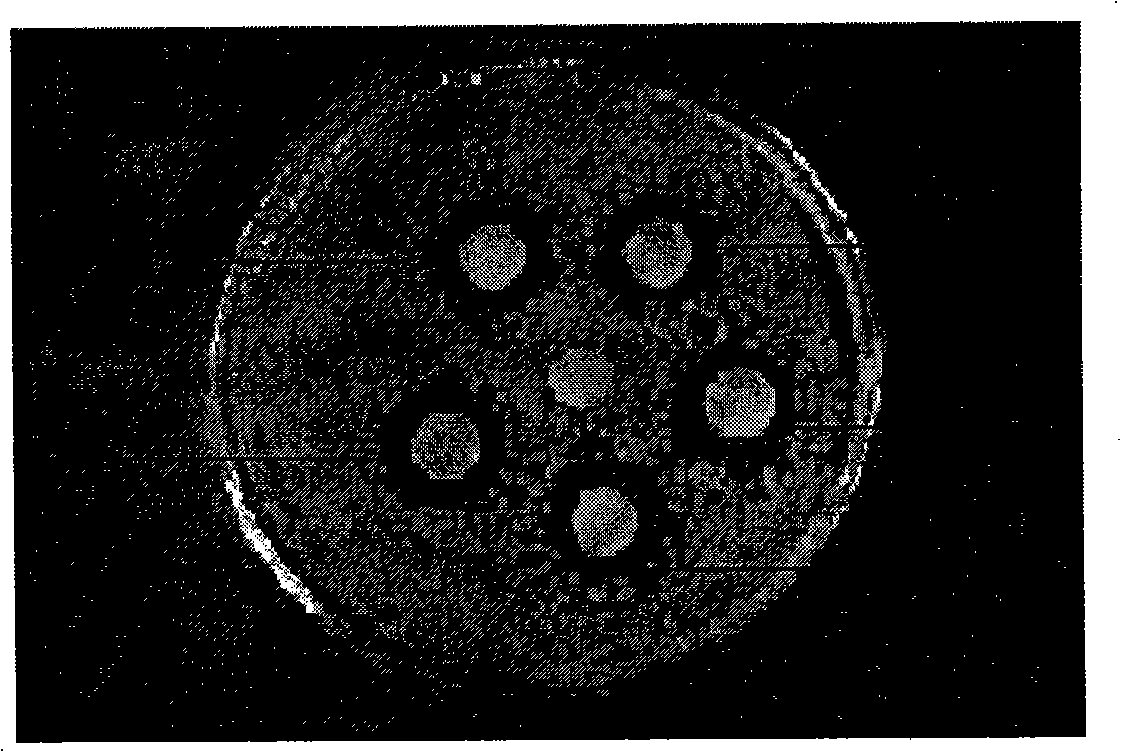

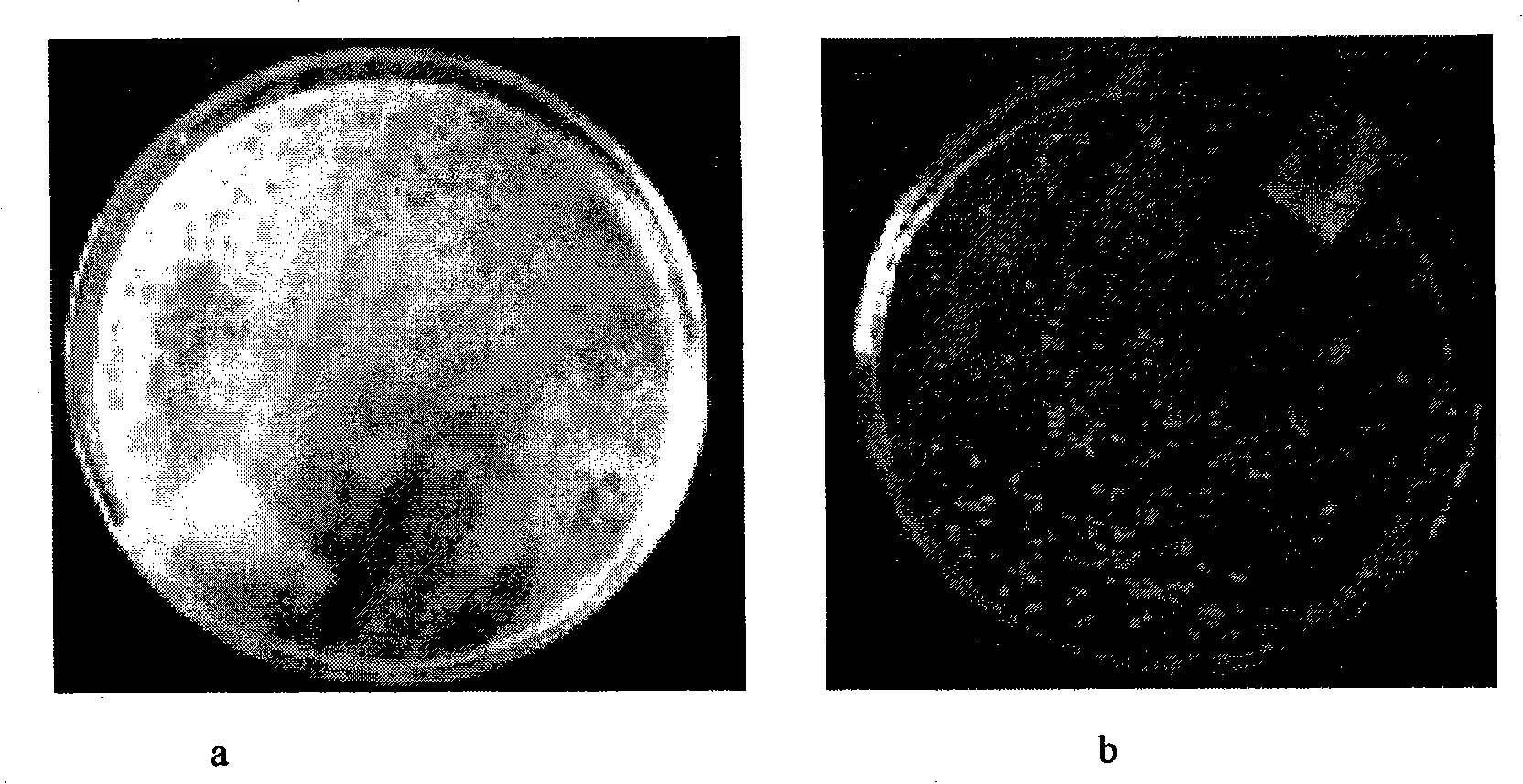

[0037] The prepared Ag 2 MoO 4 -ZnMoO 4 -CuMoO 4 The amount of antibacterial agent is added to the sanitary enamel in a proportion of 1-2wt% of the total weight of the dry glaze, and stirred for about 1 hour to make the antibacterial agent in the glaze

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com