Mechanical pressure apparatus of sintering furnace

A mechanical pressure, sintering furnace technology, applied in the field of pressure devices, can solve the problems of difficult maintenance, difficult unbalanced pressure, complex structure, etc., and achieve the effects of easy assembly and disassembly, convenient pressure adjustment, and large adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

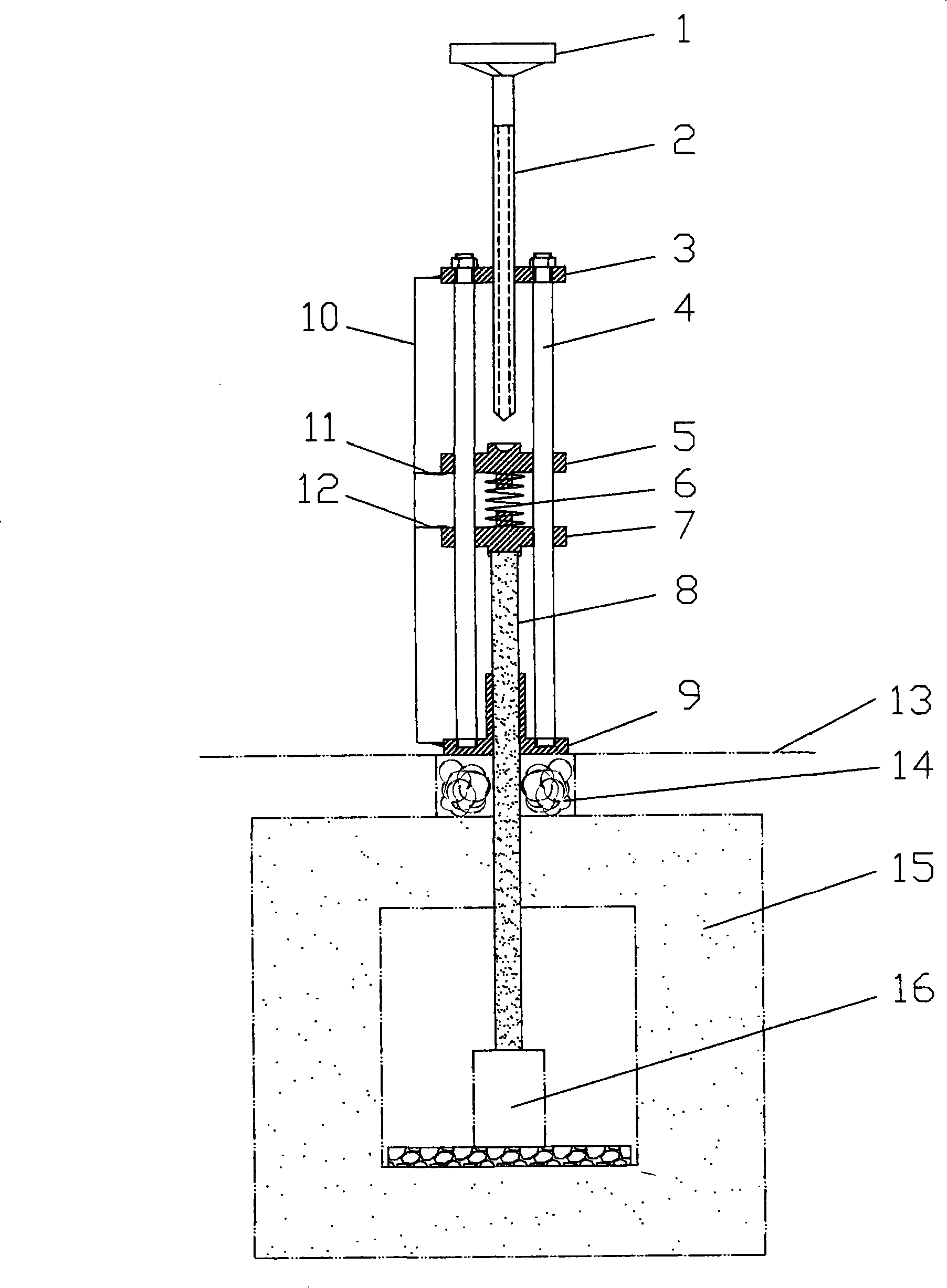

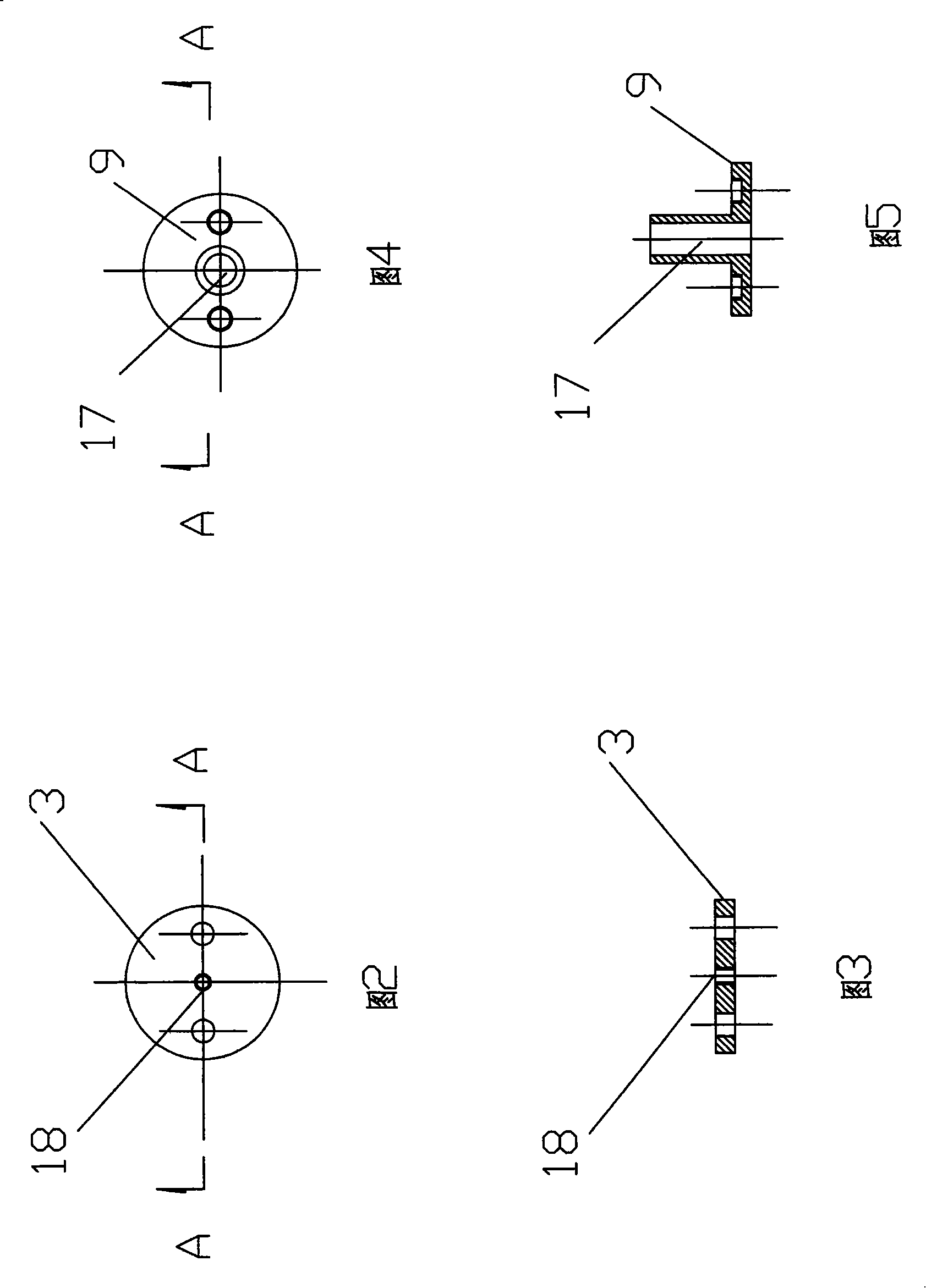

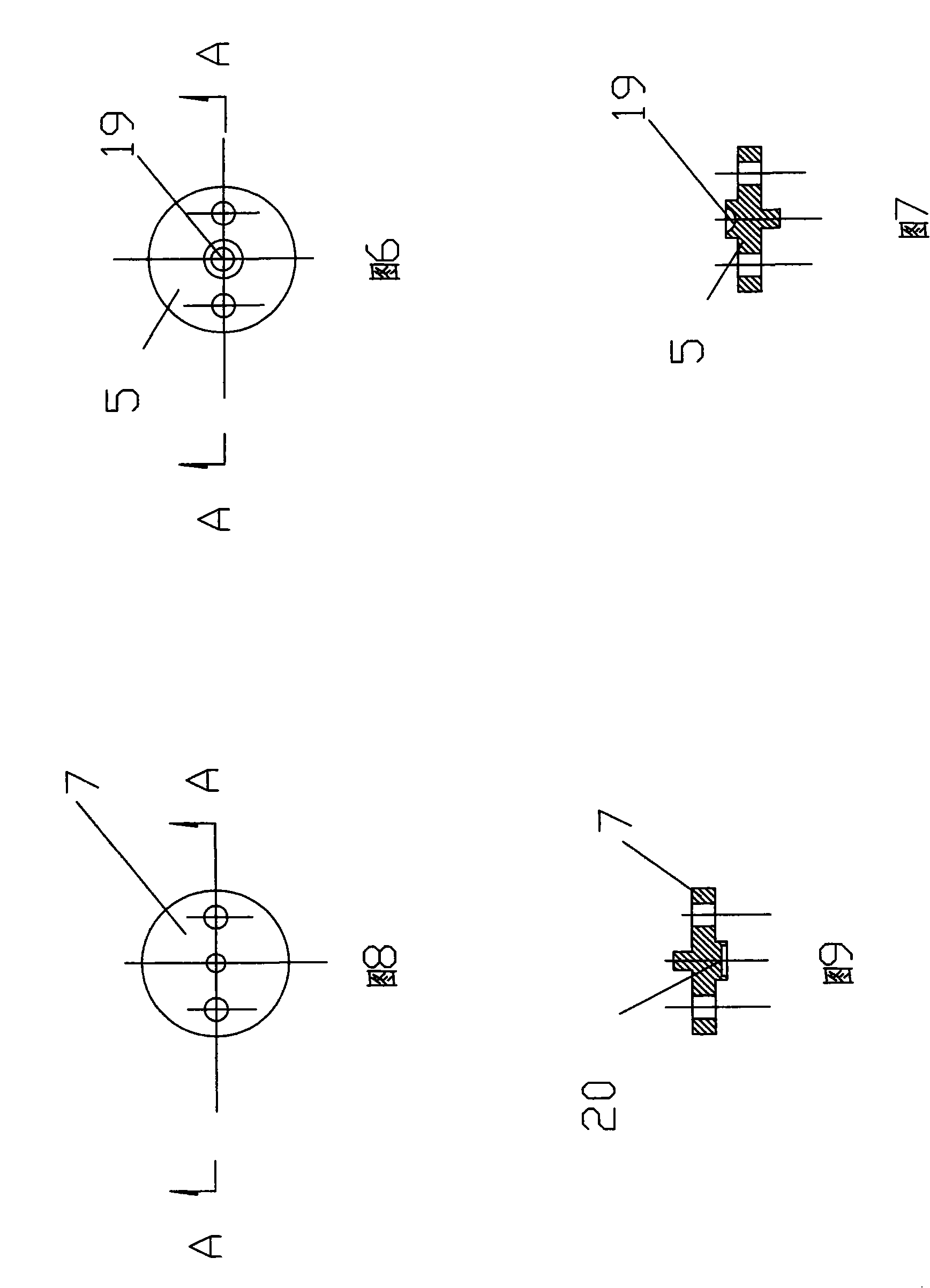

[0036] In this embodiment, the structure of the mechanical pressure device of the sintering furnace is as follows: figure 1 shown. The indenter 8 is a cylindrical indenter made of ceramic material. The support and guide mechanism includes a base 9, a guide column 4 and a cover plate 3; the shape and structure of the base 9 are as follows: Figure 4 , Figure 5 As shown, it consists of a circular chassis and a cylindrical boss located in the center of the chassis. The two are integrated structures. The center of the base is provided with a guide hole 17 that matches the indenter; the cover plate 3 is disc-shaped, such as figure 2 , image 3 As shown, the central part is provided with a screw hole 18; the guide column 4 is two, and its shape is cylindrical; the assembly method is: the center line of the cover plate 3 and the base 9 coincides, and the guide column 4 is symmetrical to the cover plate and the base. The center line is installed, and one end thereof is threadedl...

Embodiment 2

[0038] In this embodiment, six sets of mechanical pressure devices with structures as described in Embodiment 1 are installed on the atmosphere sintering furnace, and the installation method is as follows: Figure 11 , Figure 12 As shown, the base 9 is installed on the furnace body shell 13 of the atmosphere sintering furnace, surrounding the indenter 8, and an insulating sealing sleeve 14 is arranged between the furnace body shell 13 and the furnace body 15; six samples are placed in the hearth of the atmosphere sintering furnace .

[0039] Before use, first use the pressure sensor (electronic scale, the unit is kg, 1 decimal place) to check the selected six sets of force transmission springs respectively, and draw the "scale-quality" diagram of each force transmission spring.

[0040]When drawing the "scale-mass" diagram of each force transmission spring, the following points should generally be selected (the "scale-mass" diagram should be a straight line according to Hook...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com