Lift cabin door sill and its processing method

A technology for elevator doors and sills, which is applied to elevators, transportation and packaging in buildings, can solve the problems of inconvenient handling and installation, unfavorable large-scale production, long production cycle, etc., and achieves low production cost, less equipment, and less occupation. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

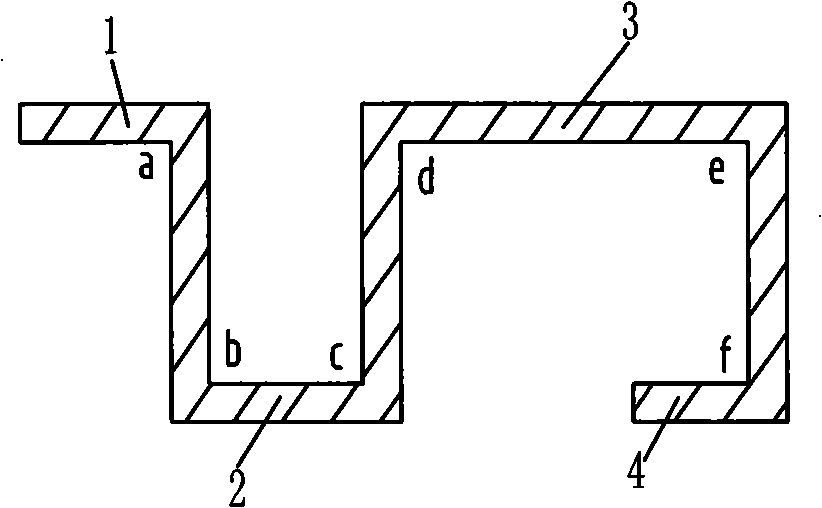

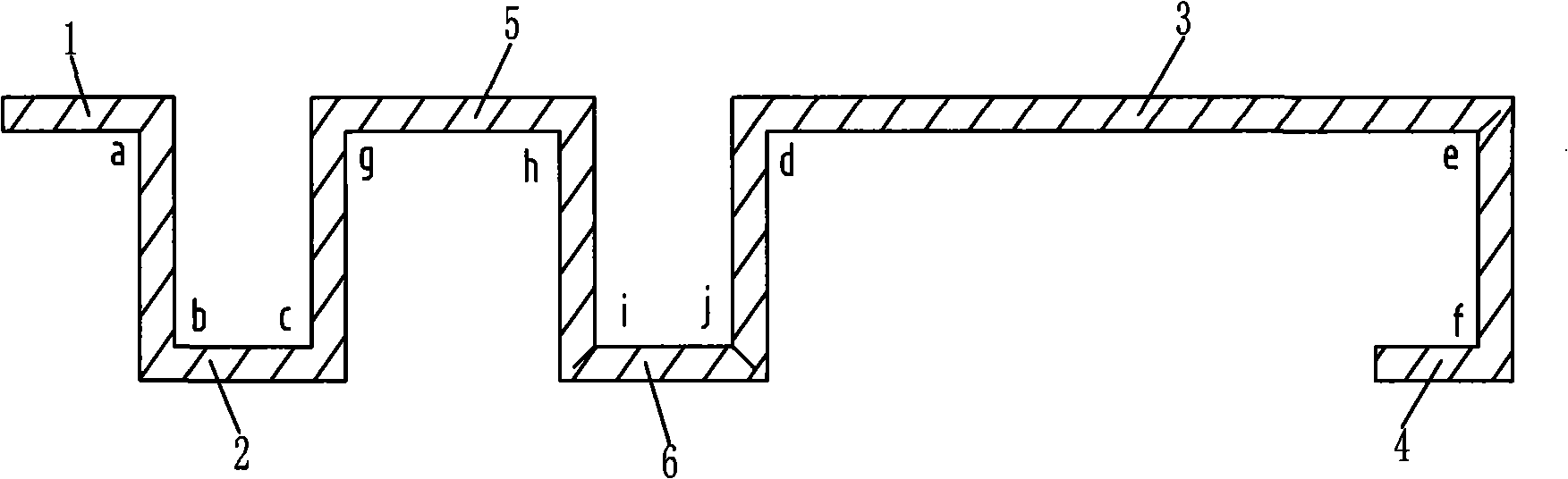

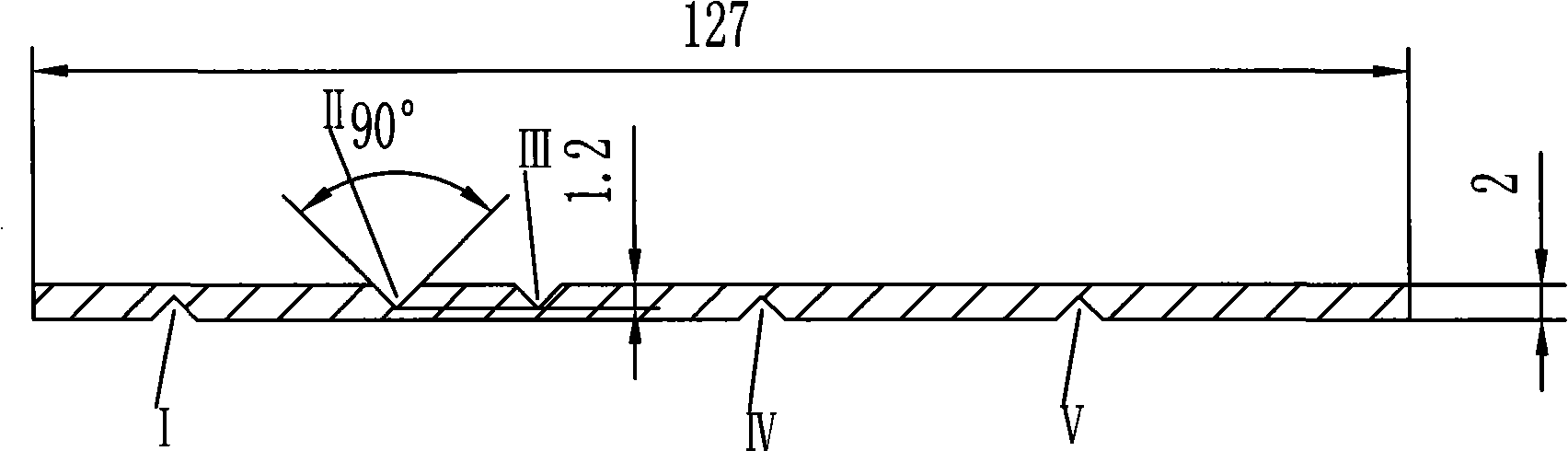

[0017] Such as figure 1 As shown, the elevator door sill is a chute structure, which is composed of a base plate 3, a chute plate 2, a bracket block 1, a hook block 4 and the bending angles connecting them. The bending angles a, b , c, d, e, f are right angles. Such as figure 2 As shown, the elevator door sill has two chute structures, which are composed of a base plate 3, a left chute plate 2, a right chute plate 6, a connecting plate 5, a bracket block 1, a hook block 4 and a bending joint between them. Angle composition, the bending angles a, b, c, d, e, f, g, h, i, j are all right angles. The sill of the elevator door has clear edges and corners, each bending angle is a right angle, the elevator door is not easy to slip out of the chute of the sill, and the safety factor is high. In order to make the elevator door sill more practical and beautiful, surface decoration treatment can be carried out by galvanizing, plastic spraying, electrophoretic paint, spraying colored ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com