Wharf crane and construction method

A technology of cranes and wharves, which is applied in the field of segmental transfer of modern long-span highways and railway super-large bridges. It can solve the problems of unsatisfactory transshipment of prefabricated beams crossing the road, no way to meet the transfer requirements, and limited trestle height. Solve the effect of landing laterally in place, maintaining the waterway, and occupying less waterway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in conjunction with the drawings, which are only for understanding the specific implementation examples of the content of the invention, and are not intended to limit the scope of protection.

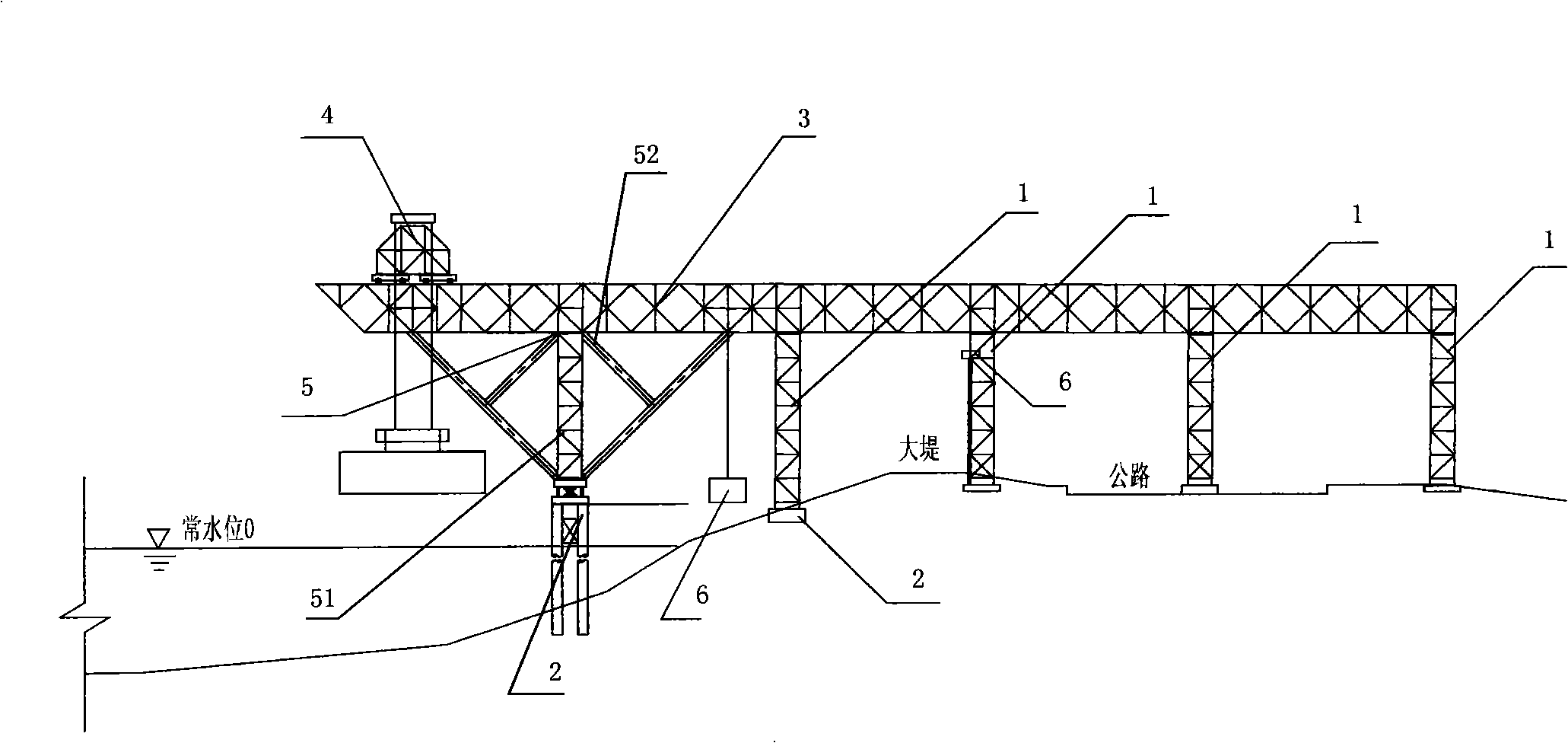

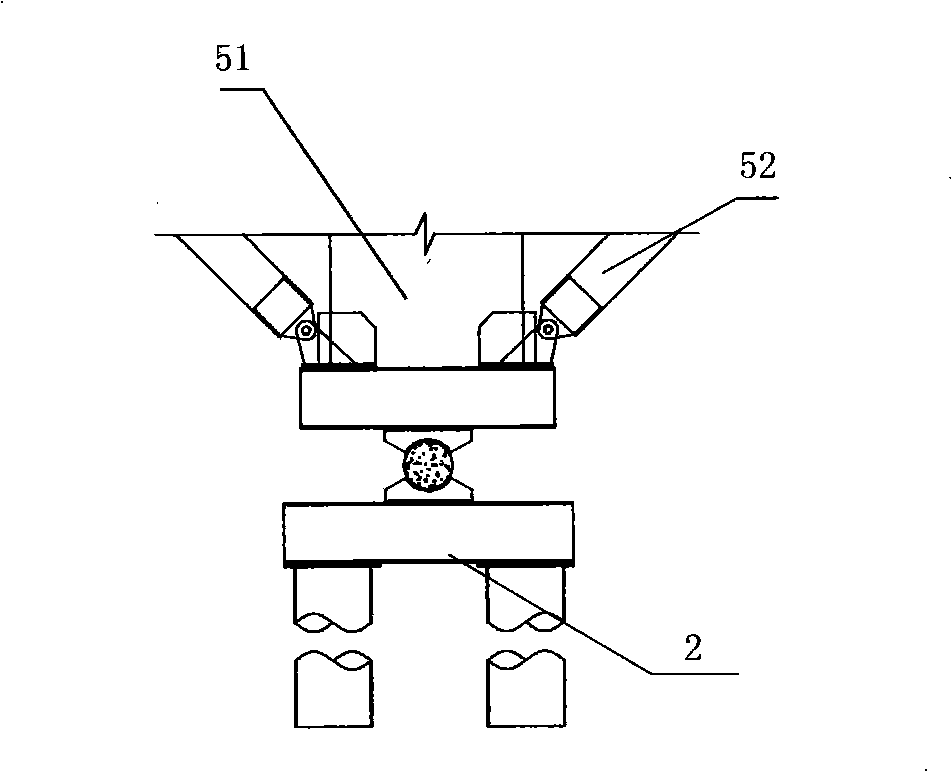

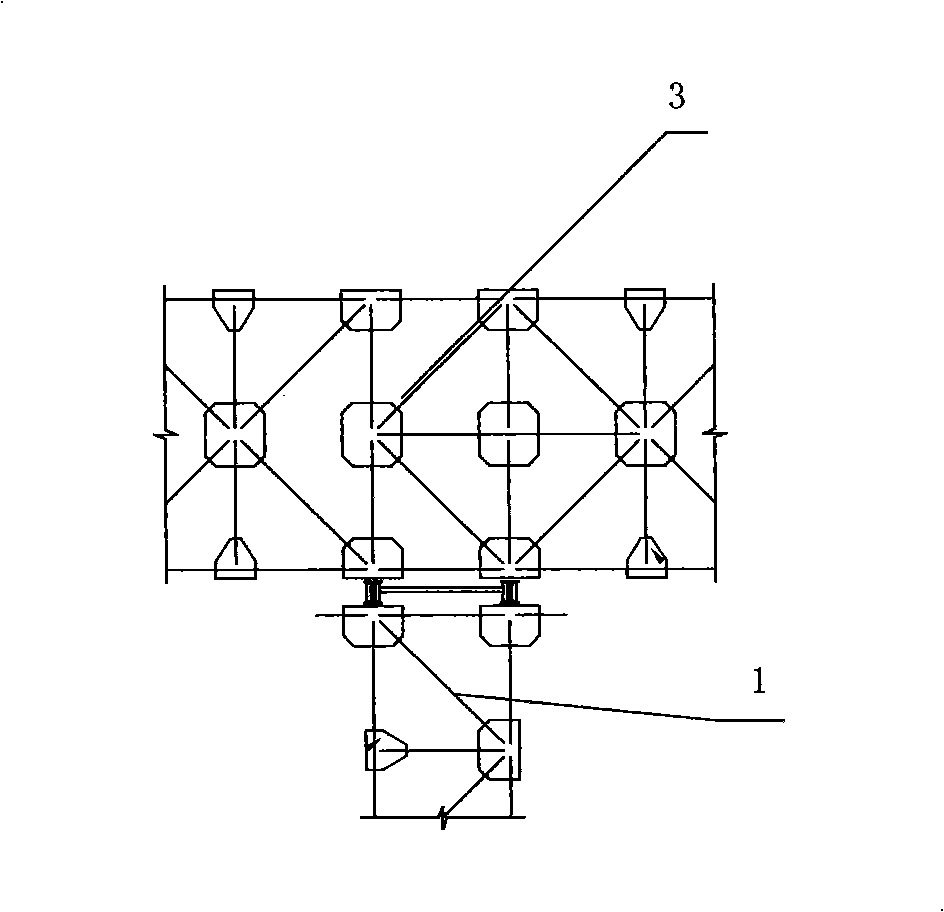

[0017] A wharf crane, comprising a plurality of sets of columns 1 and corresponding column foundations 2, a main truss 3, a lifting truss 4, a hoisting system, a fixed lifting point composed of pulley blocks, a crane running system, and a cantilever 5, the cantilever 5 The front end of the main truss is composed of a column 51 and a steel pipe triangular support 52, the lower end of which is hinged to the column foundation 2, and the other columns 1 are fixedly connected to the column foundation 2. The column 2 close to the cantilever is flexibly connected with the main truss 3 . A counterweight 6 is provided inside the steel pipe triangular support 52 . At the same time, a counterweight is also provided at the column 2 near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com