Helix TWT slow wave component and production method

A technology of helical wire and traveling wave tube, which is applied in the field of helical wire traveling wave tube slow wave components, can solve the problems of low thermal conductivity, achieve the effects of reducing product price, avoiding difficult processing, and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

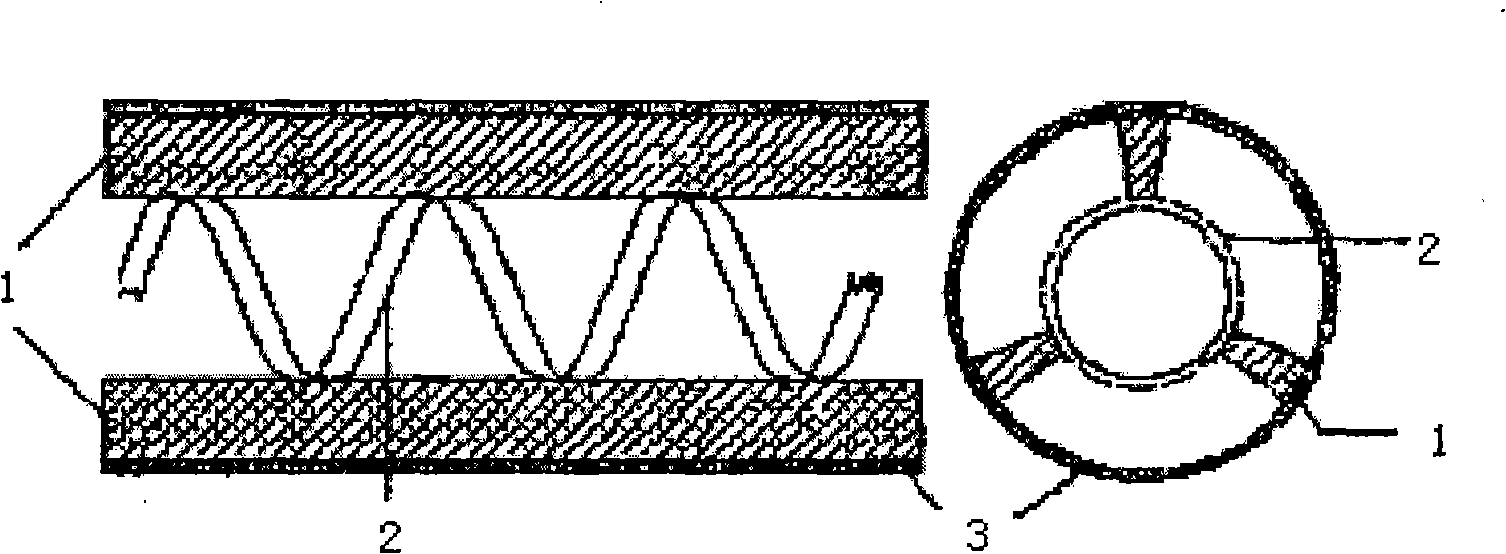

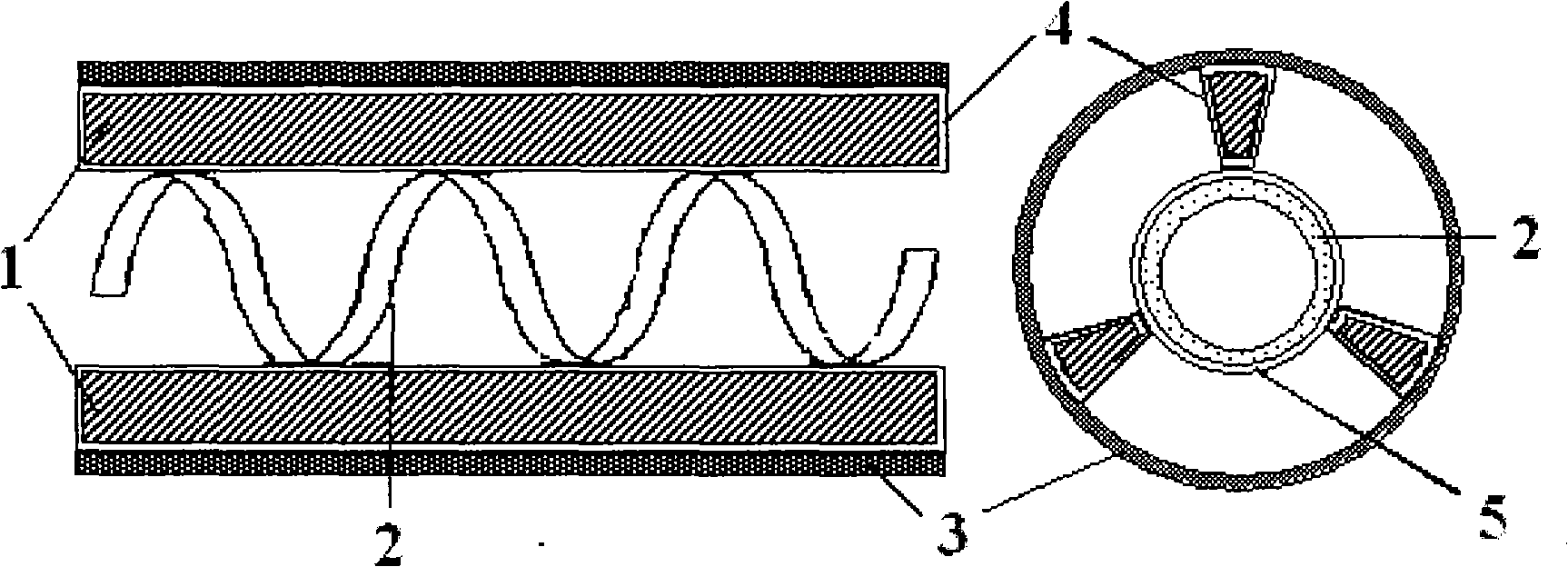

[0019] Such as figure 2 As shown, it is a schematic diagram of a helical slow wave structure with strong heat dissipation capacity composed of a medium holding rod and a helix for depositing a diamond film of the present invention. The present invention uses a medium holding rod 1 for depositing a diamond film and a helix for depositing a diamond film 2 and the metal shell 3 form a slow wave component. Including: a medium clamping rod 1, a helix 2, a tube shell 3, a first diamond film 4 and a second diamond film 5, the inner wall of the tube shell 3 is in close contact with the diamond film 4 on the surface of the medium clamping rod 1, and the medium clamps The diamond film 4 on the surface of the rod 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com