Combined protective container

A protective container and composite technology, which is applied in the field of heat insulation and refractory equipment, can solve the problems of not being able to directly reduce the amount of heat radiation, not being able to save special items, and having less heat radiation delaying effect, so as to achieve low production costs and improve impact resistance. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

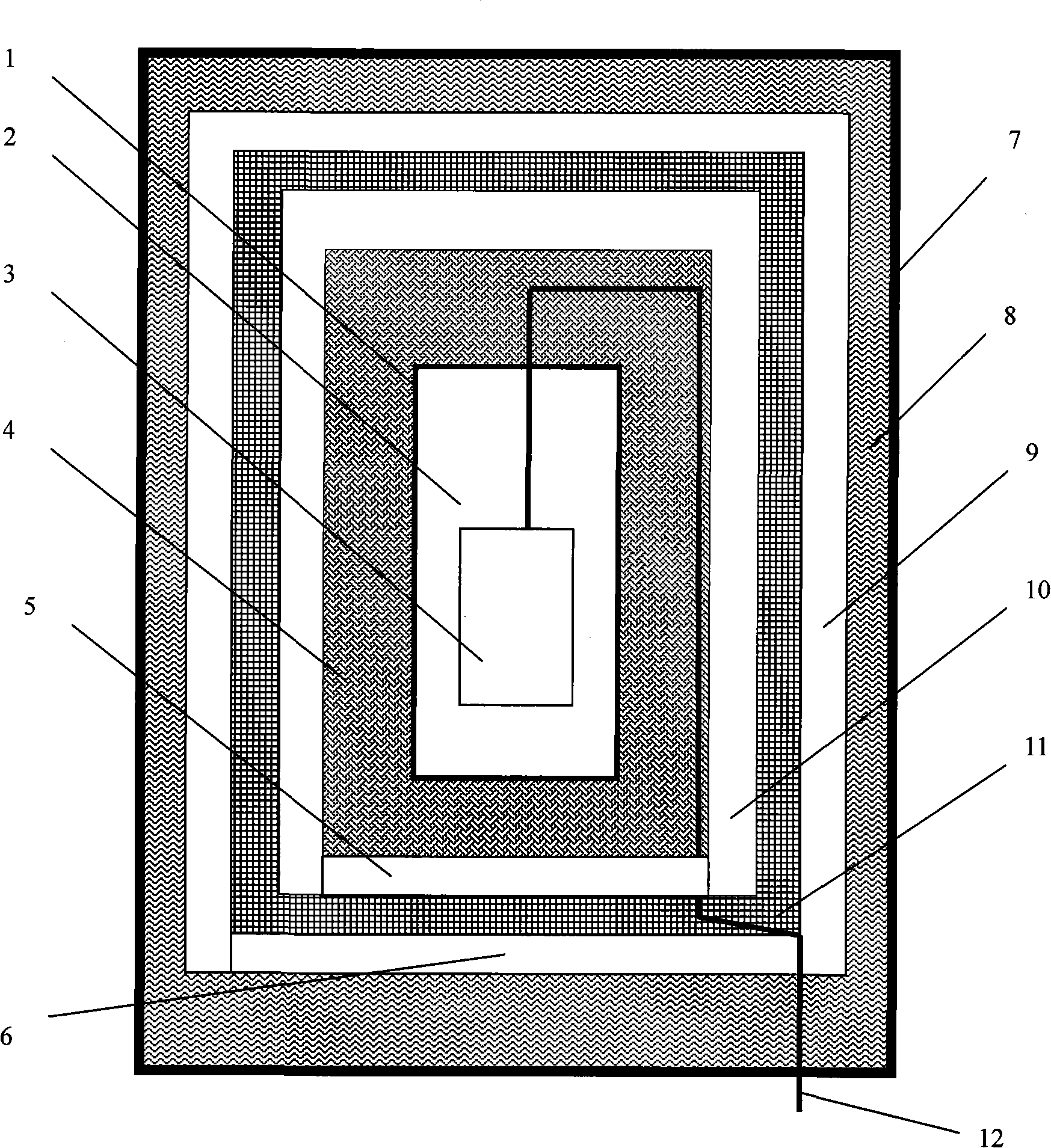

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] see figure 1 , the composite protective container provided by the embodiment of the present invention includes an inner shell 1 and an outer shell 7 . A sealed cubic cavity 2 is enclosed by the inner casing 1, and the cavity 2 is used to place data storage devices or electronic devices 3 that need to be protected and record data information.

[0016] Outside the inner shell 1 is a first heat insulating material layer 4 made of heat insulating material asbestos. The asbestos material is tightly wrapped outside the inner shell 1 to form a first heat insulating material layer 4 with substantially uniform thickness on six sides. A first cup-shaped vacuum body 10 made of double-layer glass is sheathed on the first heat insulating ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com