Doping semi-conductor nanocrystalline and preparation thereof

A nanocrystal and semiconductor technology, which is applied in the field of doped semiconductor nanocrystal and its preparation, can solve the problems of small coverage of fluorescence peak position, difficulty in doping elements, difficulty in controlling doping amount, etc., and achieves easy doping amount Control, avoid use, good effect of monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

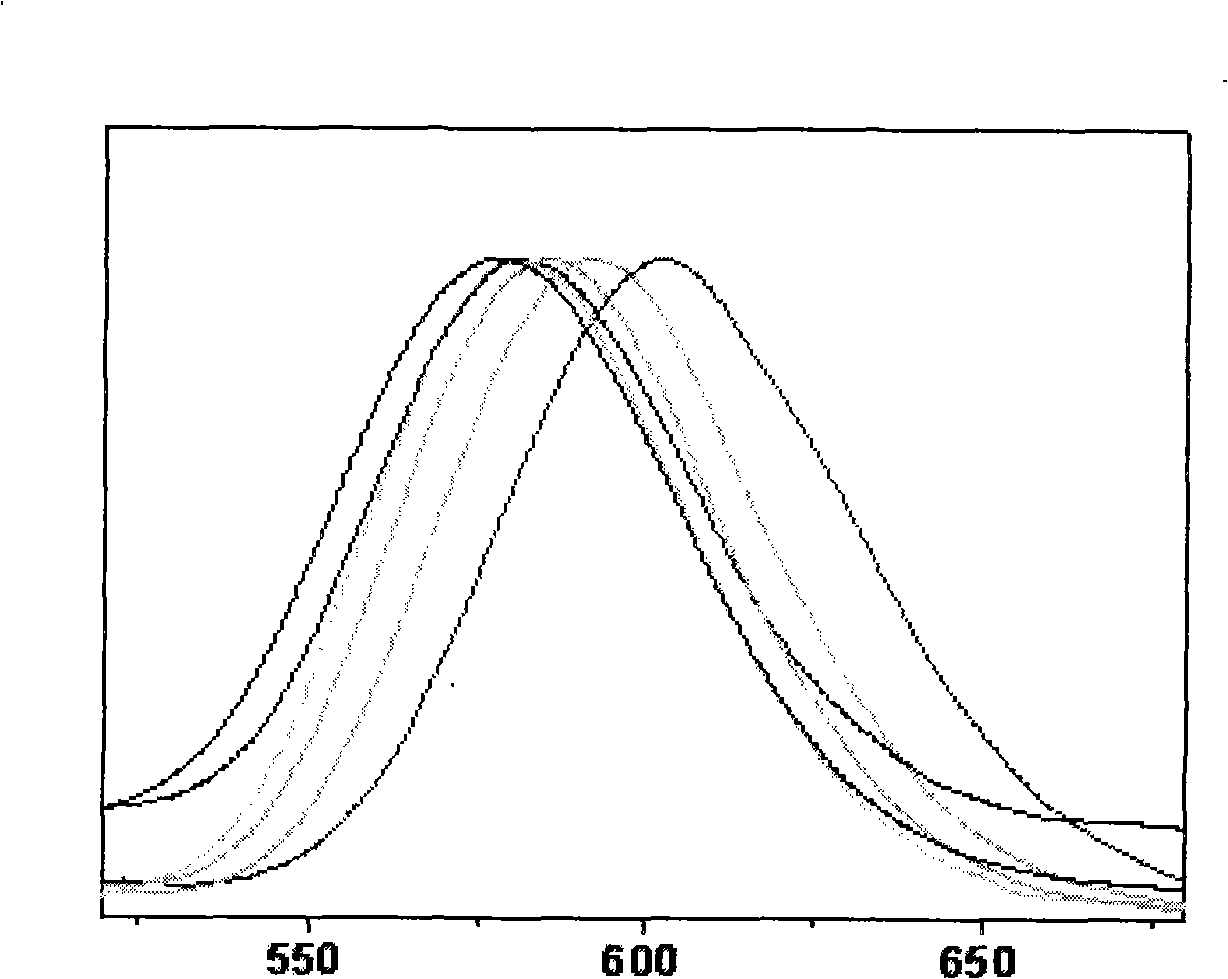

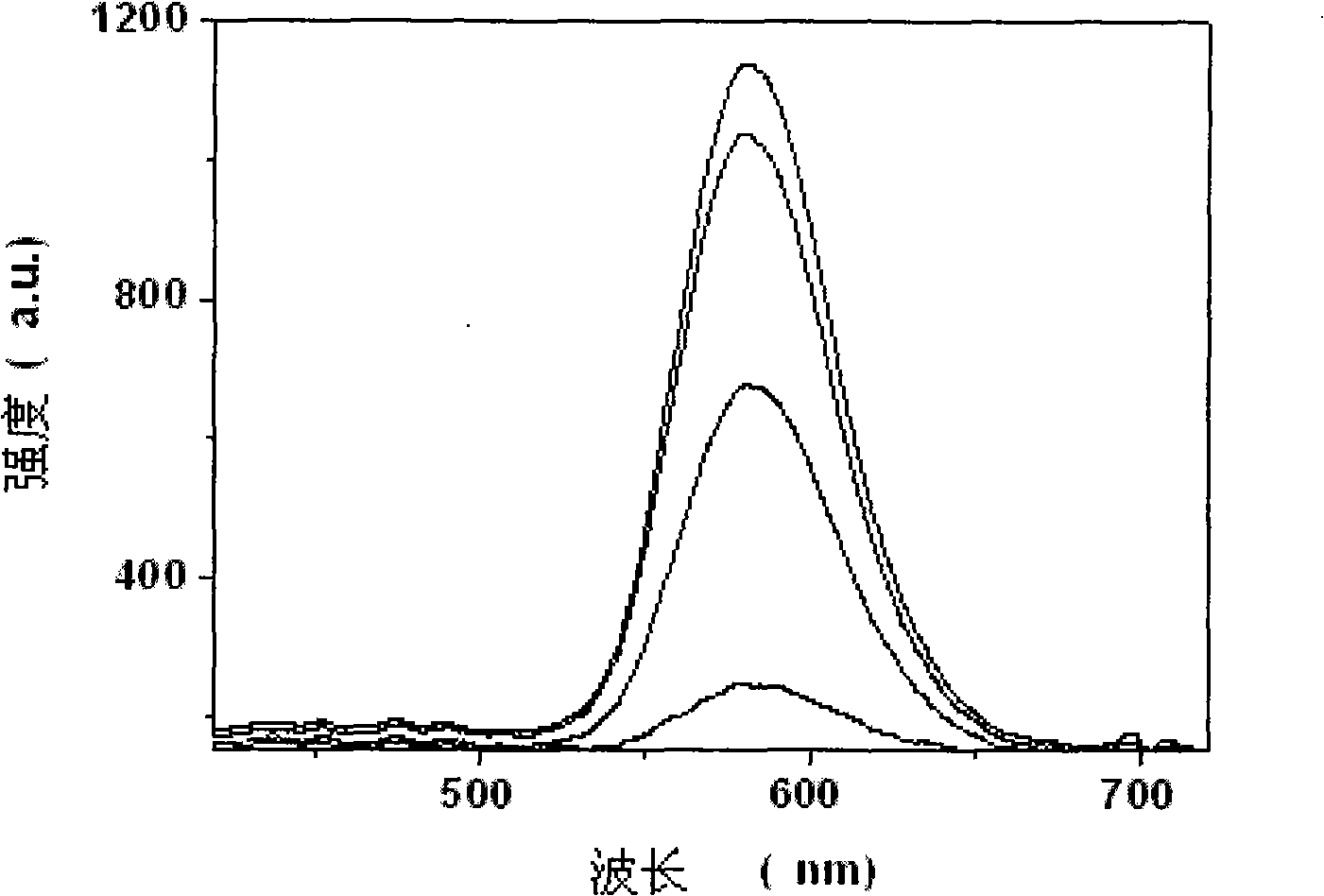

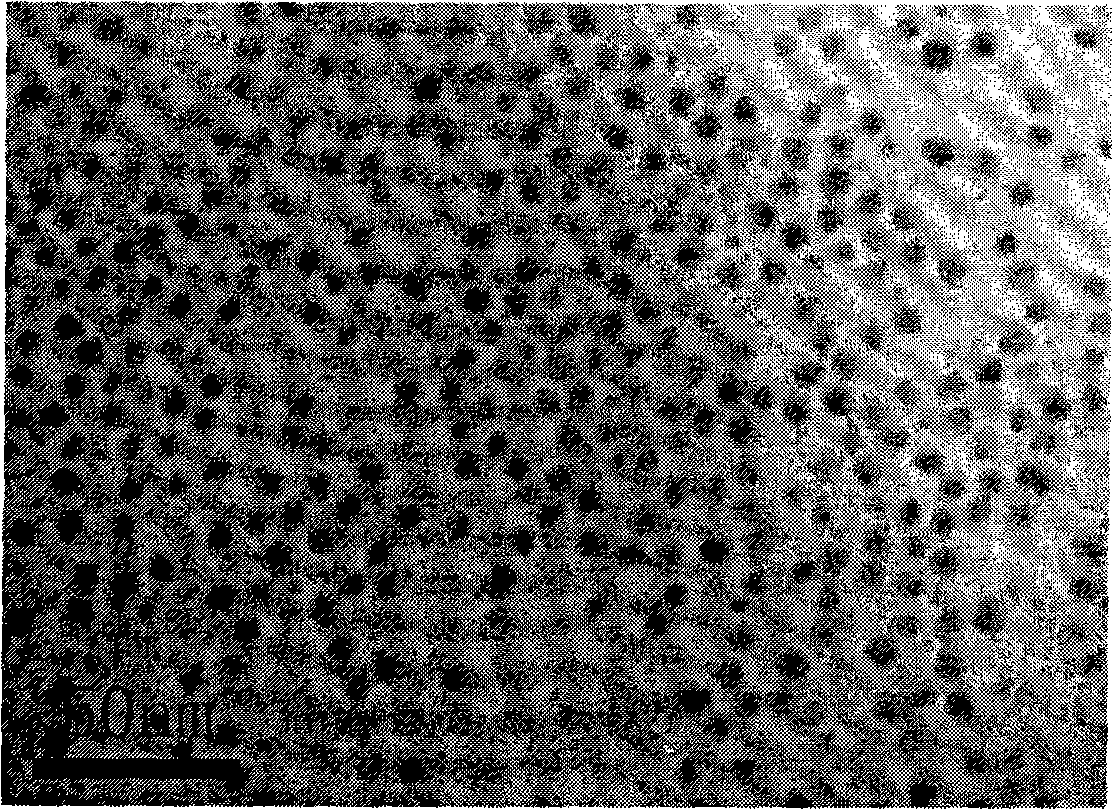

[0024] Get 0.02g (0.03mmol) of manganese stearate and 6g of octadecene and mix them into a 50ml three-neck bottle, heat to 100°C under nitrogen atmosphere and keep for 30 minutes, then rapidly heat up to 300°C and inject 4ml of 0.1M Se solution ( 1mmolSe and 3mmol octadecylamine dissolved in 10ml octadecene, the same below), cooled to 260°C for growth for one hour, then raised the temperature to 280°C and added dropwise 0.4ml 0.3M zinc stearate precursor solution (3mmol stearate Dissolve the acid in 10ml of octadecene, the same below), after reacting for 10 minutes, cool down to 270°C, add 0.4ml of zinc stearate, cool down to 260°C, add 0.4ml of zinc stearate, react for 10 minutes, cool down to 240°C and Add 1ml of zinc stearate precursor dropwise, then add 1.8ml of S solution (0.1M, 2mmol sulfur dissolved in 20ml of octadecene, the same below) and 0.6ml of zinc stearate mixed solution to grow according to the atomic layer epitaxial growth method The first layer, 2.4ml S and 0...

Embodiment 2

[0026] Take 0.05g (0.08mmol) of manganese stearate and 6g of octadecene, mix them into a 50mL three-neck bottle, heat to 100°C under nitrogen atmosphere and keep it for 30 minutes, then quickly raise the temperature to 300°C, inject 1ml of 0.1M Se solution, and cool down Grow at 260°C for one hour, then raise the temperature to 280°C and add 0.4ml of 0.3M zinc stearate precursor solution dropwise. After reacting for 10 minutes, cool down to 260°C and add 0.5ml of zinc stearate. Cool down to 240°C and add 1.6ml S (0.1M) and 0.5ml zinc stearate mixed solution to grow the first layer in turn according to the atomic layer epitaxy growth method, 2.0ml S and 0.7ml zinc stearate solution to grow the second layer, 2.5 The third layer was grown by ml S and 1ml zinc stearate solution, and finally MnSe / ZnSe / ZnS doped core-shell structure nanocrystals were formed. The interval between each addition was 10 minutes. After adding the last layer, reflux at 180°C for 1 hour . Samples were tak...

Embodiment 3

[0028]Take 0.015mmol of manganese oleate and 6g of octadecene, mix them into a 50ml three-neck bottle, heat to 100°C under nitrogen atmosphere and keep it for 30 minutes, then quickly raise the temperature to 250°C, inject 2ml of 0.05M Se solution, and raise the temperature to 280°C Grow for 90 minutes, then add 0.2ml of 0.3M zinc stearate precursor solution dropwise, react for 10 minutes, then cool down to 270°C, add 0.2ml of zinc stearate, cool down to 260°C, add 0.3ml of zinc stearate, and react for 10 minutes After cooling down to 240°C, add 0.5ml of zinc stearate precursor dropwise, then add 0.9ml of S solution (0.1M) and 0.3ml of zinc stearate mixed solution to grow the first layer according to the atomic layer epitaxial growth method, 1.2ml S and 0.4ml zinc stearate solution to grow the second layer, 1.5ml S and 0.5ml zinc stearate solution to grow the third layer, finally forming MnSe / ZnSe / ZnS doped core-shell structure nanocrystals, adding S each time The interval bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com