Apparatus to reduce the cost of renewable hydrogen fuel generation by electrolysis using combined solar and grid power

An electrolyzer and utility power technology, applied in electrolysis components, electrolysis process, single-network parallel feeding arrangement, etc., can solve problems such as lack of economy, inability to use electrolyzers, and increase in size and cost of electrolyzers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following description of the embodiments is merely exemplary in nature and is in no way intended to limit the invention and its application or uses.

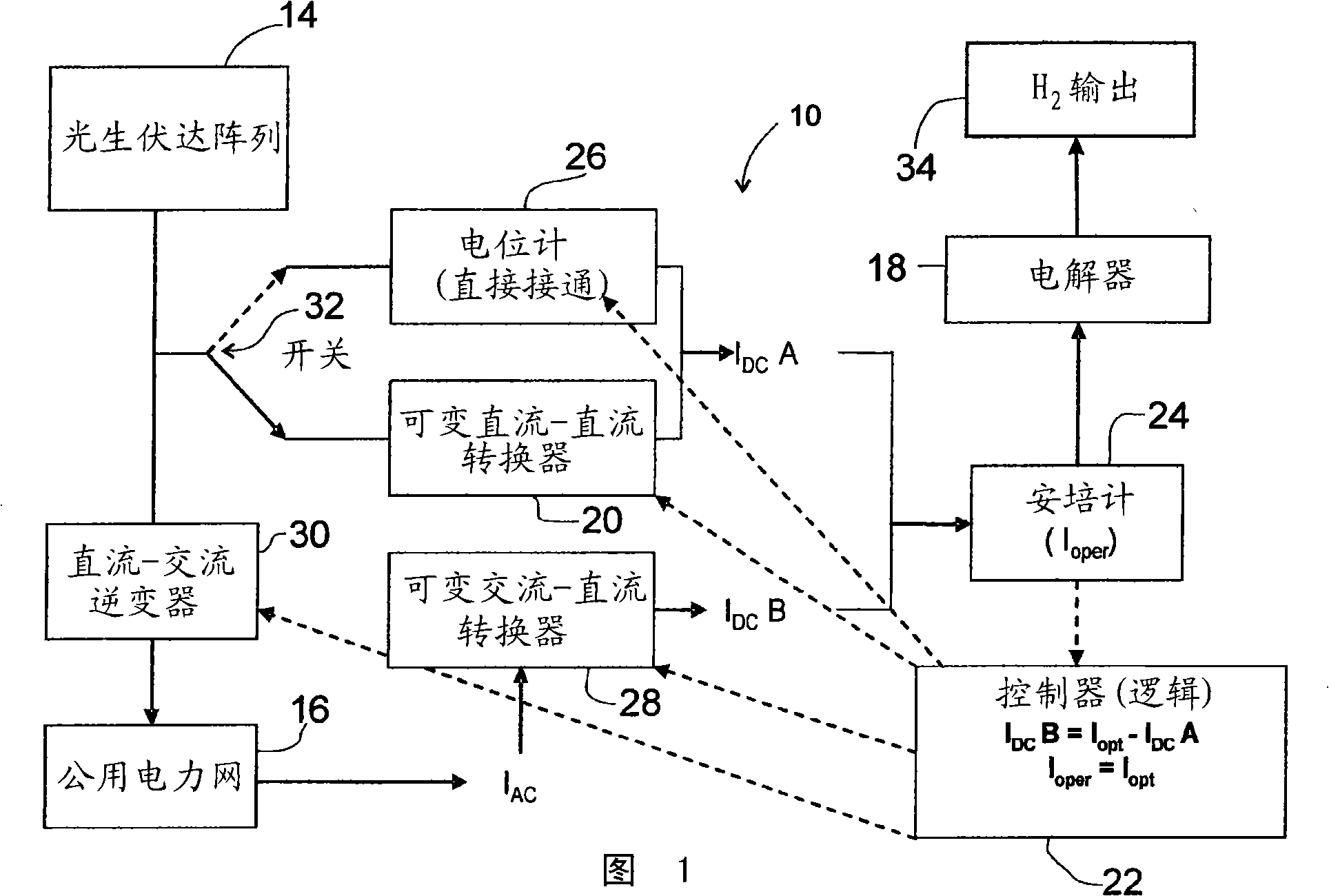

[0012] FIG. 1 is a block diagram of a product 10 including a power control system 12 . Power control system 12 combines at least one of photovoltaic power (DC current) from photovoltaic array 14 or AC power from utility power grid 16 to power electrolyzer 18 . Photovoltaic array 14 may be any suitable photovoltaic array including, but not limited to, photovoltaic modules based on crystalline silicon, amorphous silicon, cadmium telluride, and copper indium diselenide. These photovoltaic modules may include, but are not limited to, the Sharp NT-S5E1U module manufactured by Sharp Electronics Corp. Huntington Beach, California and available from AAPS Alternative Power Systems, Carlsbad, California, USA; manufactured by SanyoSolar (Sanyo Electric Co., Ltd, part of Japan) as the SanyoHIP-190BA3 module available from Altern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com