Electroformed mold and manufacturing method therefor

A manufacturing method and electroforming technology, applied in electroforming and electrolysis processes, etc., can solve the problems of deformation of medium flow channels, difficulty in forming forming surfaces with complex shapes, and inability to ensure rigidity, etc., and achieve good durability, excellent cooling performance, The effect of a reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

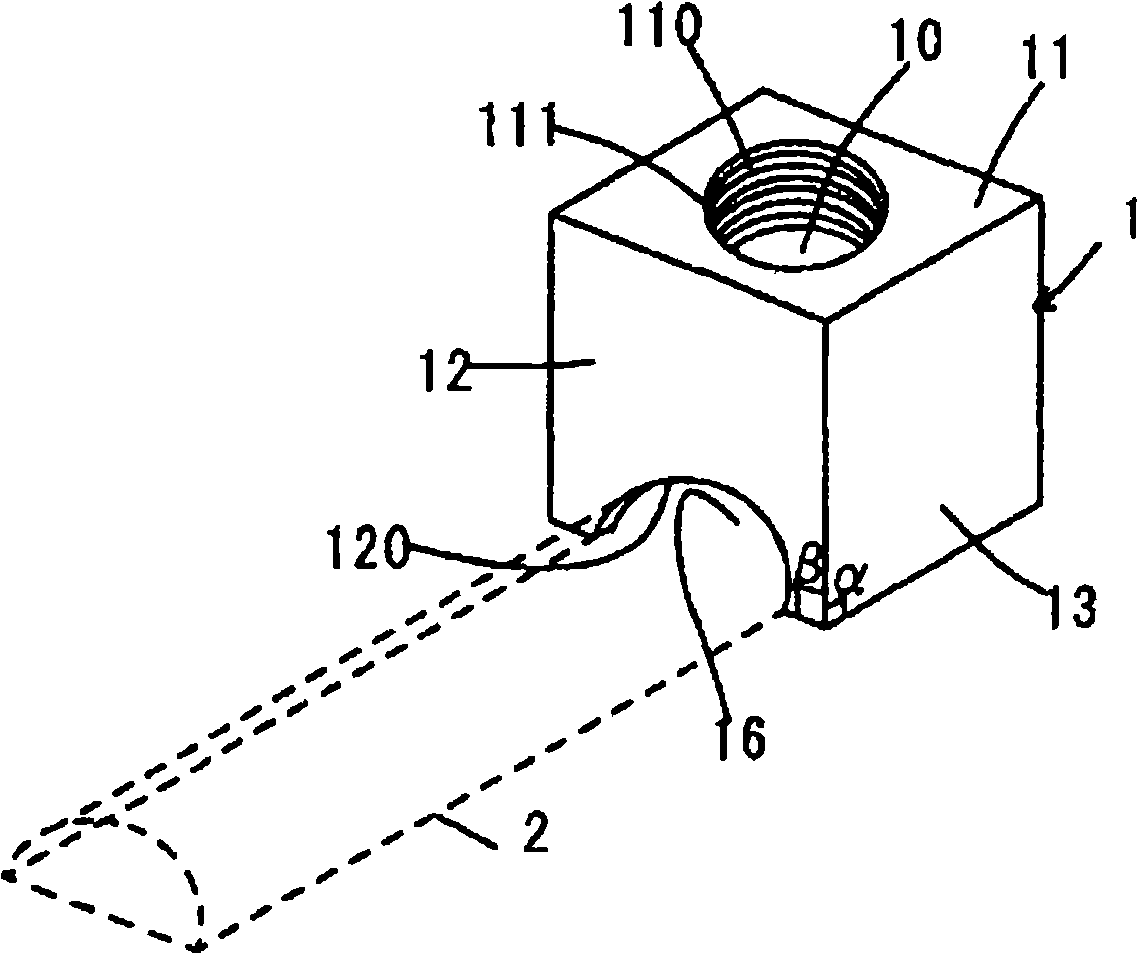

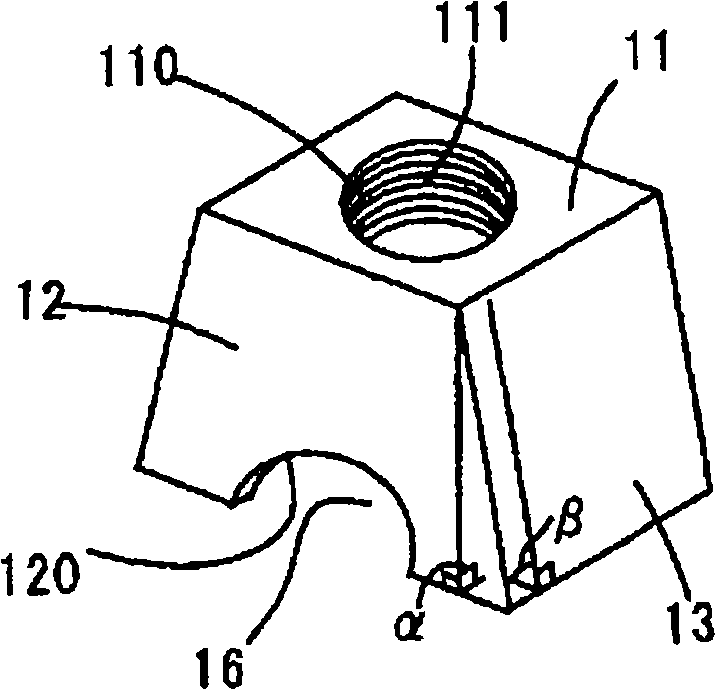

[0080] According to the electroforming mold of the present invention, there are medium flow passages formed in the electroforming shell. Preferably, the cross-sectional shape of the medium flow channel is a non-recessed shape, such as semicircle, rectangle, square and trapezoid. The non-lower concave shape refers to a shape in which, when projecting the medium flow channel from above, there is no lower portion hidden by its upper portion from being seen from above. If the shape of the medium flow channel is a lower concave shape, when the medium flow channel is projected from above, a part of it is covered by its upper part and cannot be seen from above. Compared with the above case, the shape of the medium flow channel is not lower. In the case of shapes, the deposition of electroformed metal can be improved.

[0081] Preferably, the medium flow channel has a width ranging from 5 mm to 15 mm. In the case where the width of the medium flow channel is less than 5 mm, the flow...

no. 2 approach

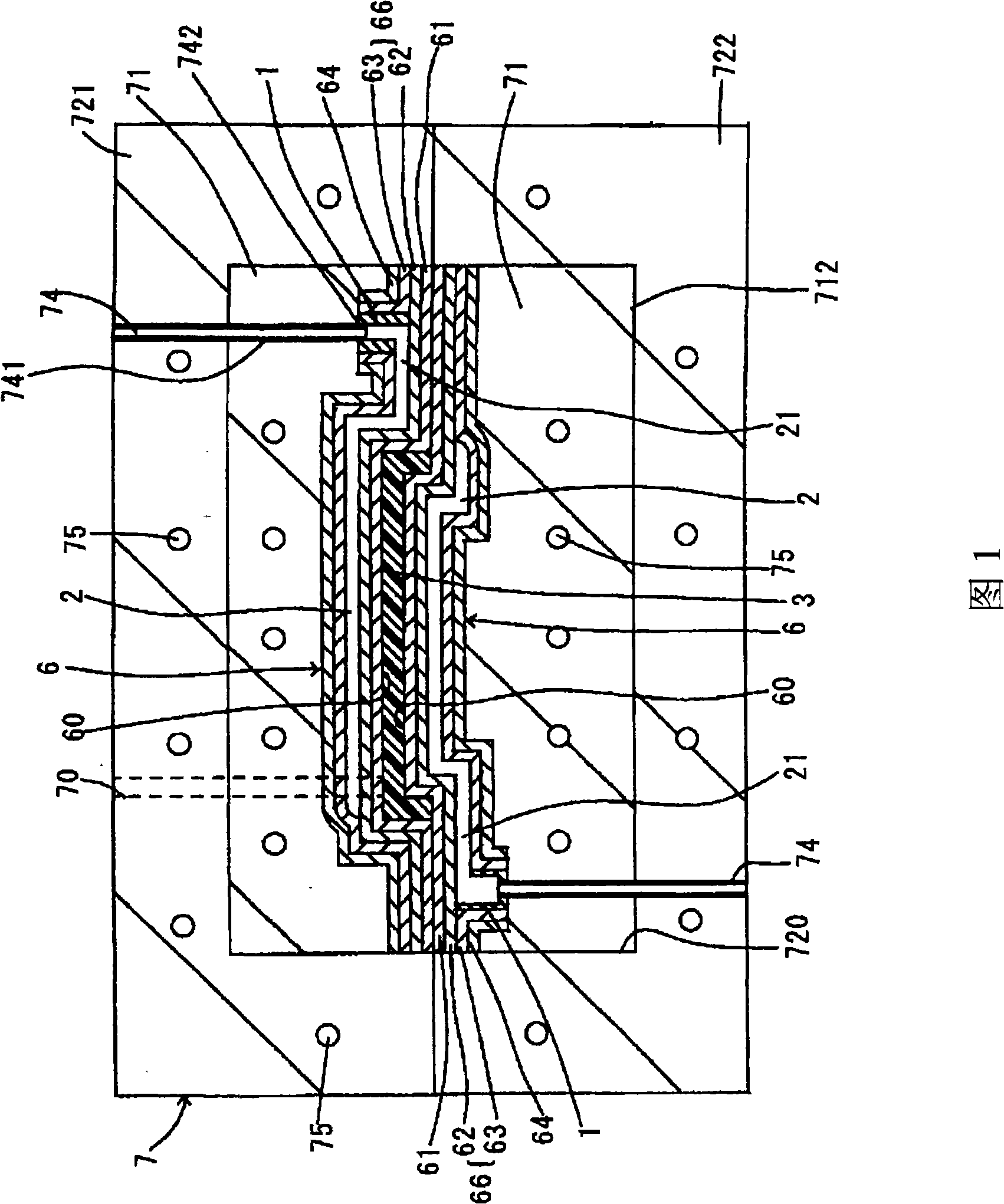

[0131] The electroforming casing formed in the electroforming mold according to the present invention has: a molding layer whose surface serves as a molding surface; a temperature regulating part in which a medium flow channel is formed between the first heat conducting layer and the second heat conducting layer and a reinforcing layer formed opposite to the shaping layer.

[0132] The shaping layer, the first thermally conductive layer, the second thermally conductive layer, and the reinforcing layer are all formed by an electroforming process. During electroforming, an electrolytic reaction is used to energize an electrolyte solution containing metal ions, and the target metal is deposited on the transfer surface of the master mold.

[0133] The first heat conducting layer and the second heat conducting layer are made of the same metal. The first and second thermally conductive layers may be made of high thermally conductive materials including copper and aluminum.

[0134...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com