Automatic weighing type fluid state material metering instrument

A technology of material measurement and automatic weighing, which is applied in the direction of weighing, instruments, and weighing equipment for materials with special properties/forms, etc., which can solve problems such as production inconvenience, reduce errors, reduce labor intensity, and shorten operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

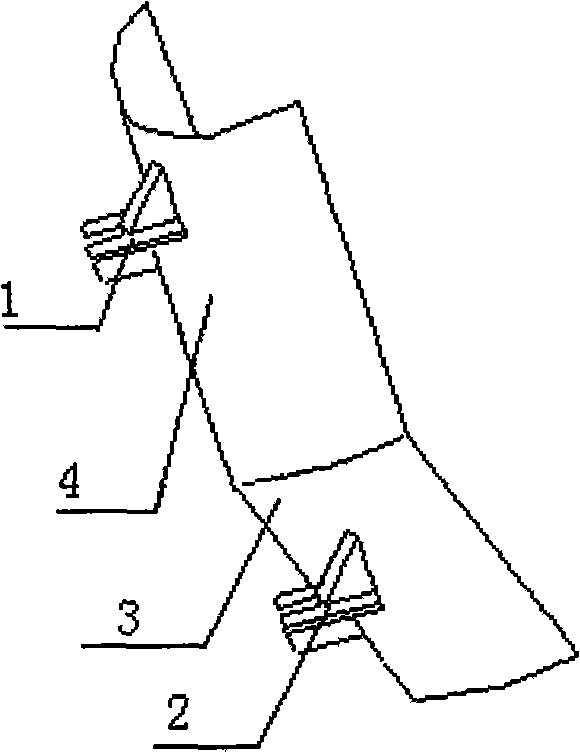

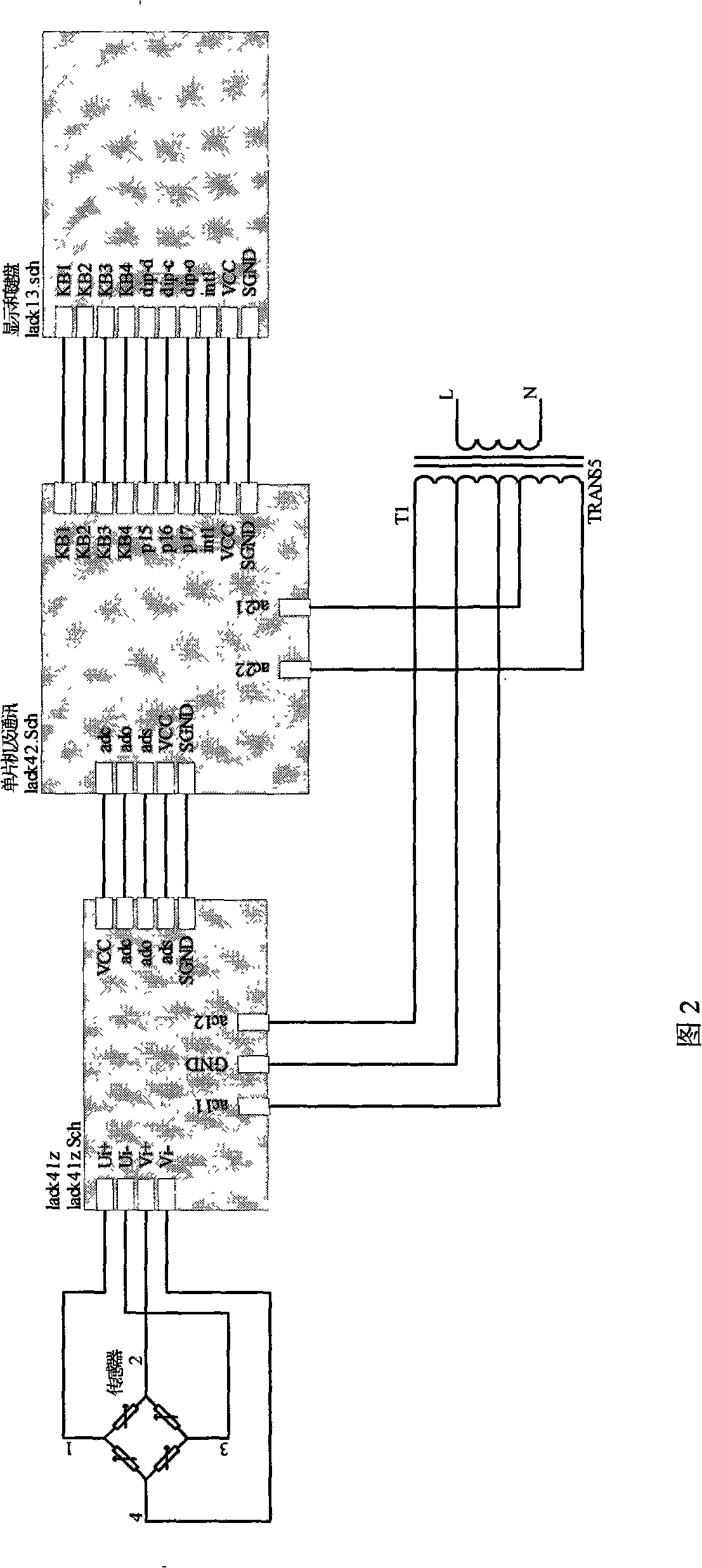

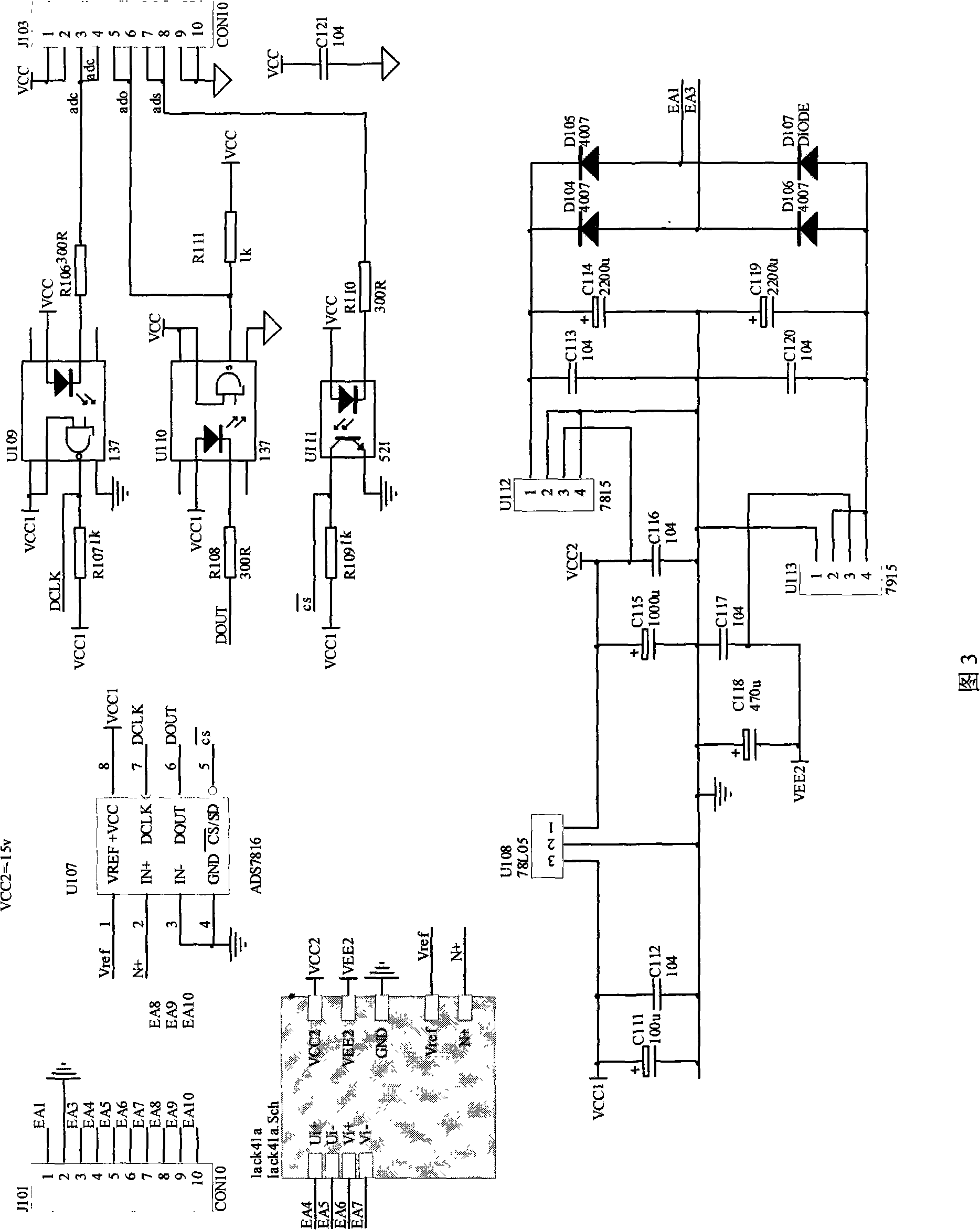

[0045]The automatic weighing type fluid state material measuring instrument of the present invention is composed of a material flow tank, a weighing sensor and a material flow controller. Material flow chute such as figure 1 The shown is composed of two semi-circular groove bodies connected up and down, the upper groove body forms an angle of 60-80 degrees with the ground, and the lower groove body forms an angle of 40-50 degrees with the ground. Equipped with a load cell. Using YZC-328S load cell, the range is 50KG and the accuracy is 1.9995mV / V. Two load cells are connected in parallel with the material flow controller. The material flow controller is composed of amplifying filter module, A / D conversion module (Figure 4), single chip system, serial communication, display and keyboard interface (Figure 5) and other parts. In this embodiment, the AD620 instrument amplifier developed by Analog Devices is used to constitute the preamplifier unit of the output signal of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com