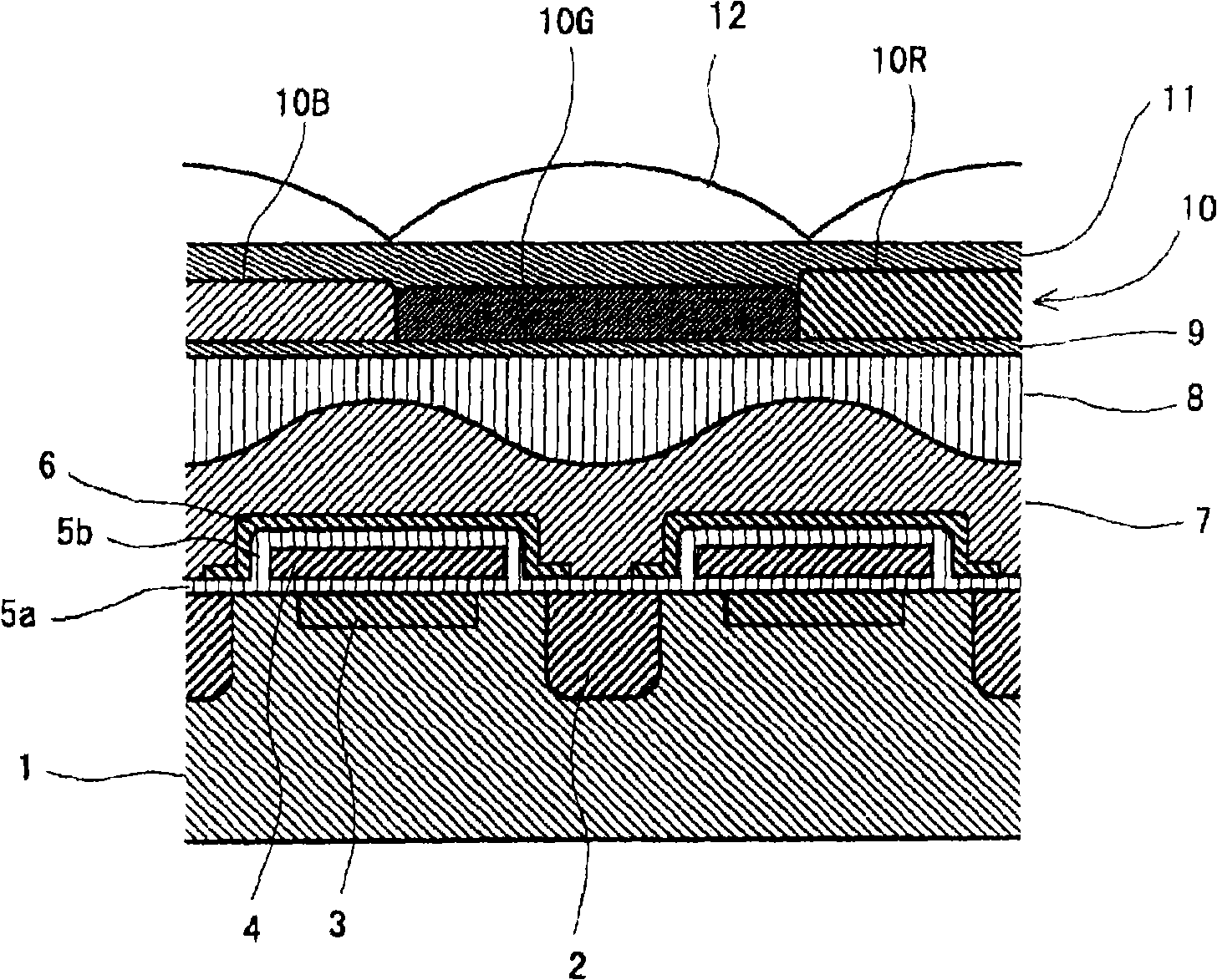

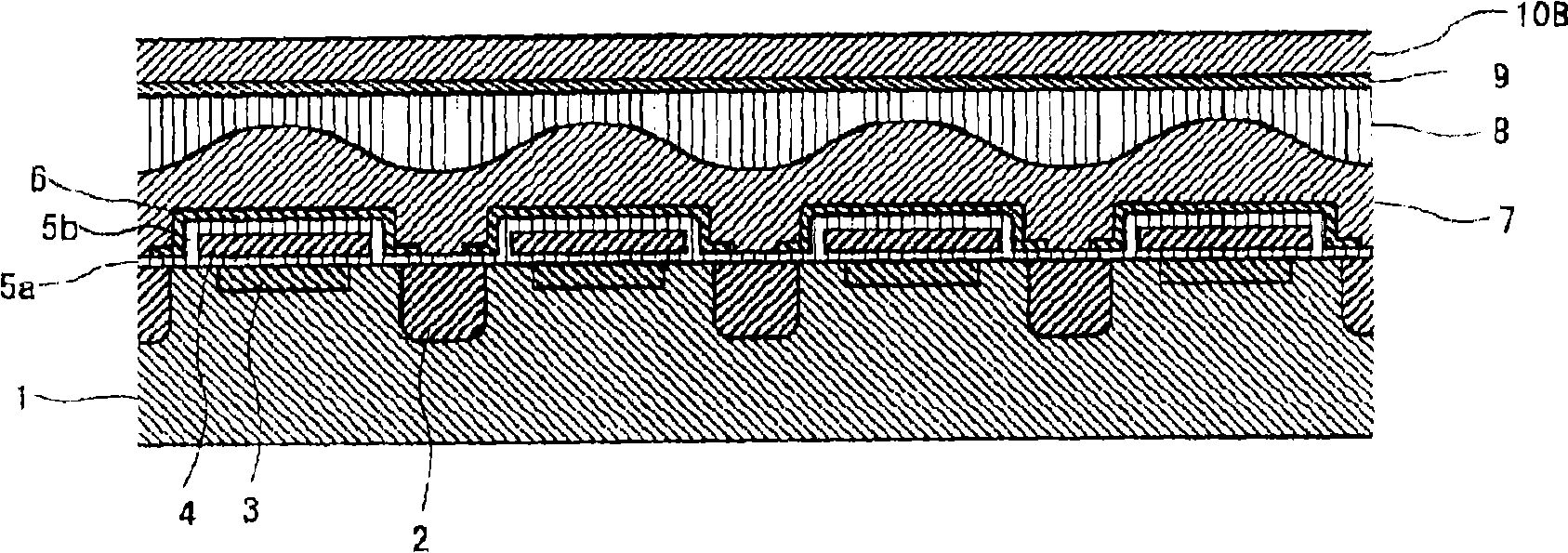

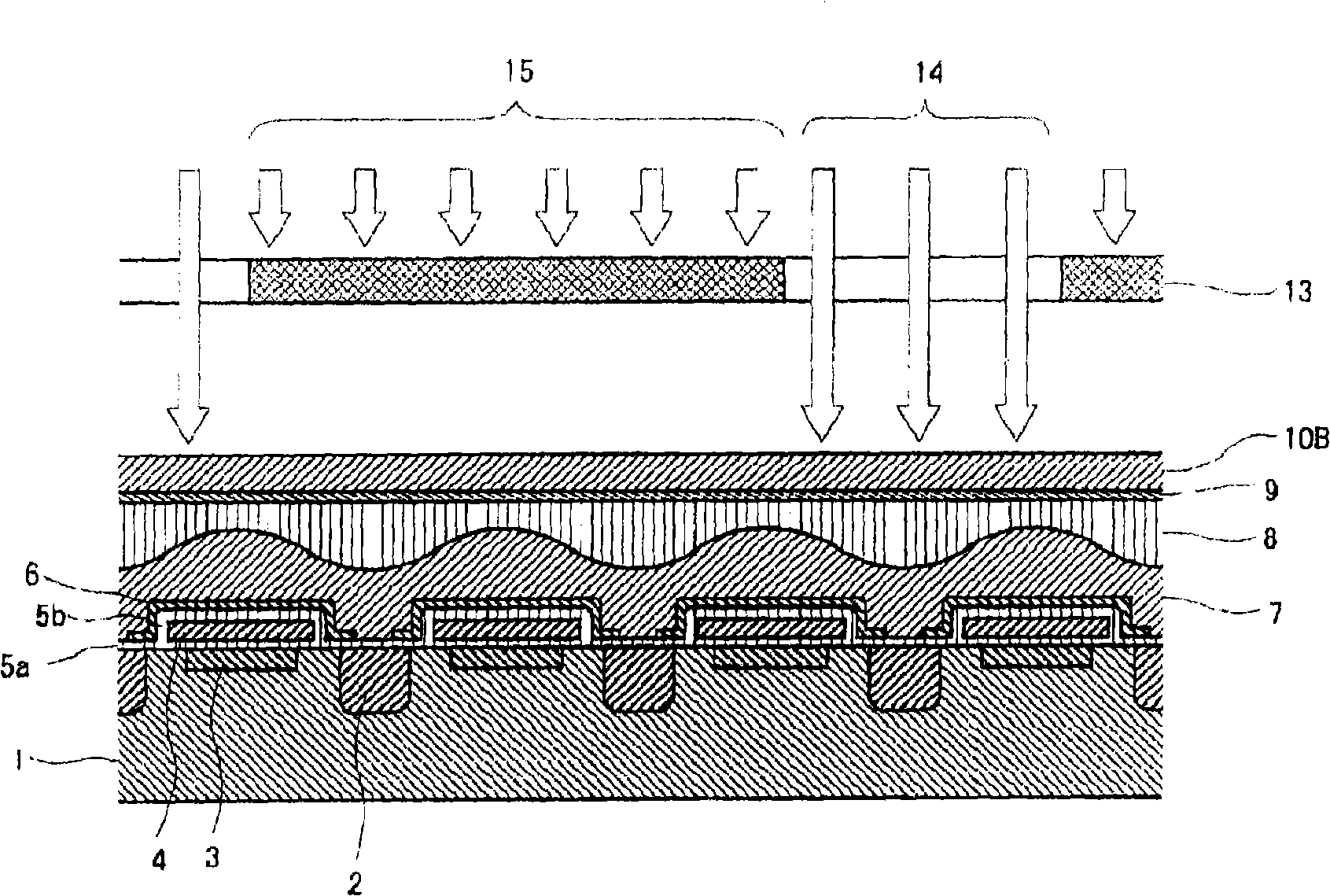

Colored photosensitive resin composition, and color filter array and solid-state image pickup device using the same

A technology of resin composition and color filter, which is applied in the direction of exposure device of photoplate making process, photosensitive material used in photomechanical equipment, instruments, etc., can solve the problem of unfavorable fine pattern and achieve the effect of improving spectral characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Synthesis Example 1 36.0 parts by weight of poly(p-hydroxystyrene) [trade name: "MARUKA LYNCURM" (manufacturer: Maruzen Petrochemical Co., Ltd.), weight average molecular weight (catalogue value): 4100, degree of dispersion ( catalog value): 1.98] and 144 parts by weight of acetone were charged into a reaction vessel, and then dissolved while stirring. 20.7 parts by weight of anhydrous potassium carbonate and 9.35 parts by weight of ethyl iodide were added to the solution, and then reflux was started by heating. After continuing to reflux for 15 hours, 72 parts by weight of methyl isobutyl ketone was added, and the organic layer was washed with 92.8 parts by weight of 2 wt % oxalic acid aqueous solution. Then, 96 parts by weight of ethyl isobutyl ketone was added, and the organic layer was washed with 64.7 parts by weight of ion-exchanged water. The washed organic layer was concentrated to 78.3 parts by weight, and after adding 187.9 parts by weight of propylene glycol...

Embodiment 2

[0102] Example 2 A blue filter was prepared in the same manner as in Example 1, except that 20 parts by mass of the colorant (I-1a) was used as the main colorant, and 10 parts by mass of the coloring agent represented by formula (IIIa) Resin A was used as an auxiliary colorant, and 49.25 parts by mass (in terms of solid content) of Resin A was used as an alkali-soluble resin.

Embodiment 3

[0103] Example 3 A blue filter was prepared in the same manner as in Example 1, except that 20 parts by mass of the colorant (II-a) was used as the main colorant, and 10 parts by mass of the colorant (II-a) represented by the formula (I-6a) The colorant of was used as an auxiliary colorant, and 49.25 parts by mass (in terms of solid content) of resin A was used as an alkali-soluble resin.

[0104]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com