Vanadium dioxide doped powder, and film and preparation method thereof

A vanadium dioxide and powder technology, applied in the field of vanadium dioxide powder preparation, can solve the problems of complex process, difficult industrialization, low visible light transmittance, etc., and achieve the effects of wide application, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

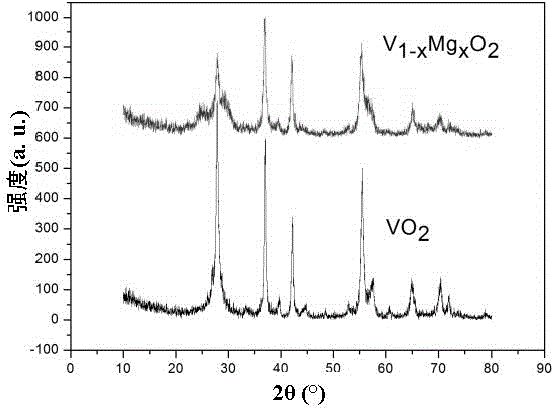

[0052] First prepare 80ml of vanadium pentoxide solution containing 0.001mol / L, add 0.001g of oxalic acid and stir to form a uniform solution. Put the solution into the reaction kettle, add the above solution and seal it. After reacting at 240°C for 24 hours, take it out after cooling, and centrifugally dry to obtain vanadium dioxide powder, whose chemical formula is VO 2 . Such as figure 1 The XRD spectrum shows that its crystal phase is M phase. The vanadium dioxide powder obtained in this example has a size of 50 nm and a phase transition temperature of 68°C.

Embodiment 2

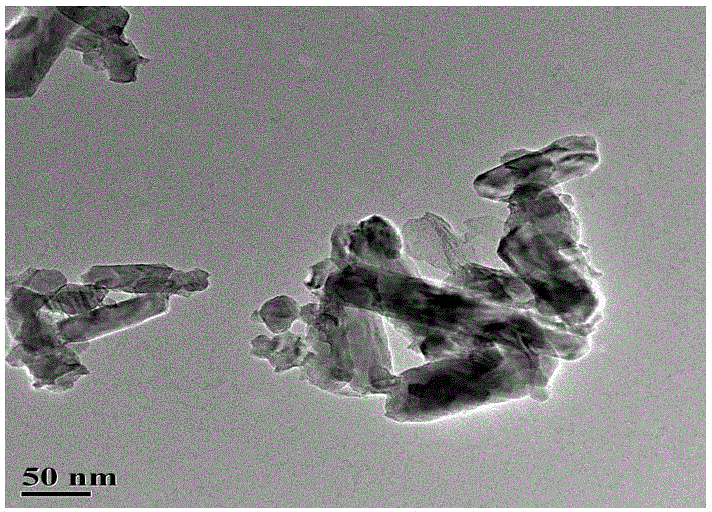

[0054] First prepare 80ml of vanadium pentoxide solution containing 0.001mol / L, add 0.005g of oxalic acid and stir to form a uniform solution. Add 2.67 mg of MgNO to the solution 3 ·6H 2 O, stir evenly, put the above solution into the reaction kettle, add the above solution and seal it. After reacting at 240°C for 24 hours, take it out after cooling, and centrifugally dry to obtain vanadium dioxide powder, whose chemical formula is V 1.94 Mg 0.06 o 2 . Such as figure 1 Its crystal phase is M phase as shown in the XRD spectrum, as figure 2 As shown in the TEM photo, the prepared vanadium dioxide powder is also in the shape of a short rod with a size of 10-300nm. The phase transition temperature of the vanadium dioxide powder prepared in this embodiment is 55°C.

Embodiment 3

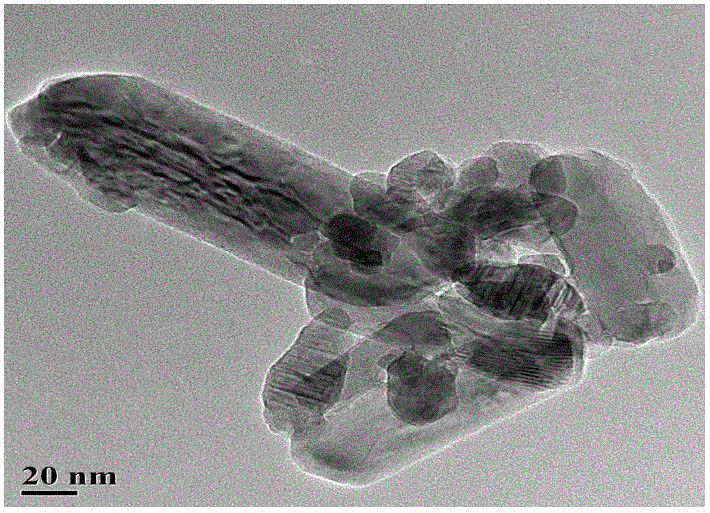

[0056]First prepare 80ml of vanadyl sulfate solution containing 0.001mol / L, and titrate with potassium hydroxide until a suspension appears. Add 5.33 mg of MgNO to the solution 3 ·6H 2 O, stir evenly, put the above solution into the reaction kettle, add the above solution and seal it. React at 240°C for 16 hours, take it out after cooling; centrifugally dry to obtain vanadium dioxide powder, whose chemical formula is V 1.9 Mg 0.1 o 2 . Such as image 3 As shown in the TEM photo, the prepared vanadium dioxide powder is also in the shape of a short rod with a size of 10-200nm. The crystal phase of the vanadium dioxide powder obtained in this example is M phase, and the phase transition temperature is 50°C.

[0057] Example, 4

[0058] First prepare 80ml of vanadyl sulfate solution containing 0.002mol / L, and titrate with potassium hydroxide until a suspension appears. Add 20 mg of MgNO to the solution 3 ·6H 2 O, stir evenly, put the above solution into the reaction ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com