Electrode device for spouting electric slurry as well as system thereof

An electrode device and electrode system technology, applied in the field of plasma jet electrode device and its system, can solve the problems of uneven treatment effect and low cost, achieve wide application range, improve industrial application surface, improve treatment area and uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and structure of the plasma jet electrode device and its system proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail below.

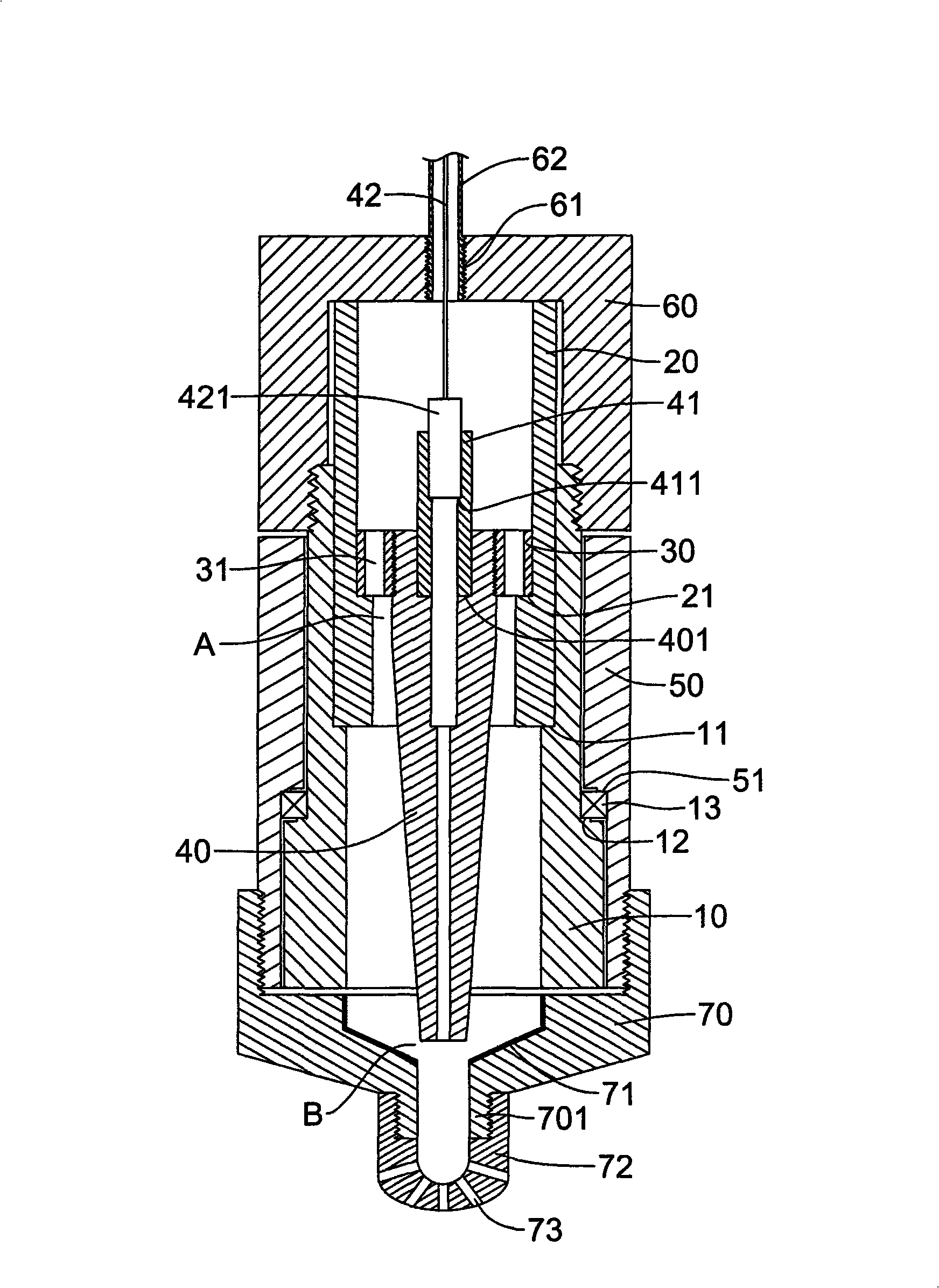

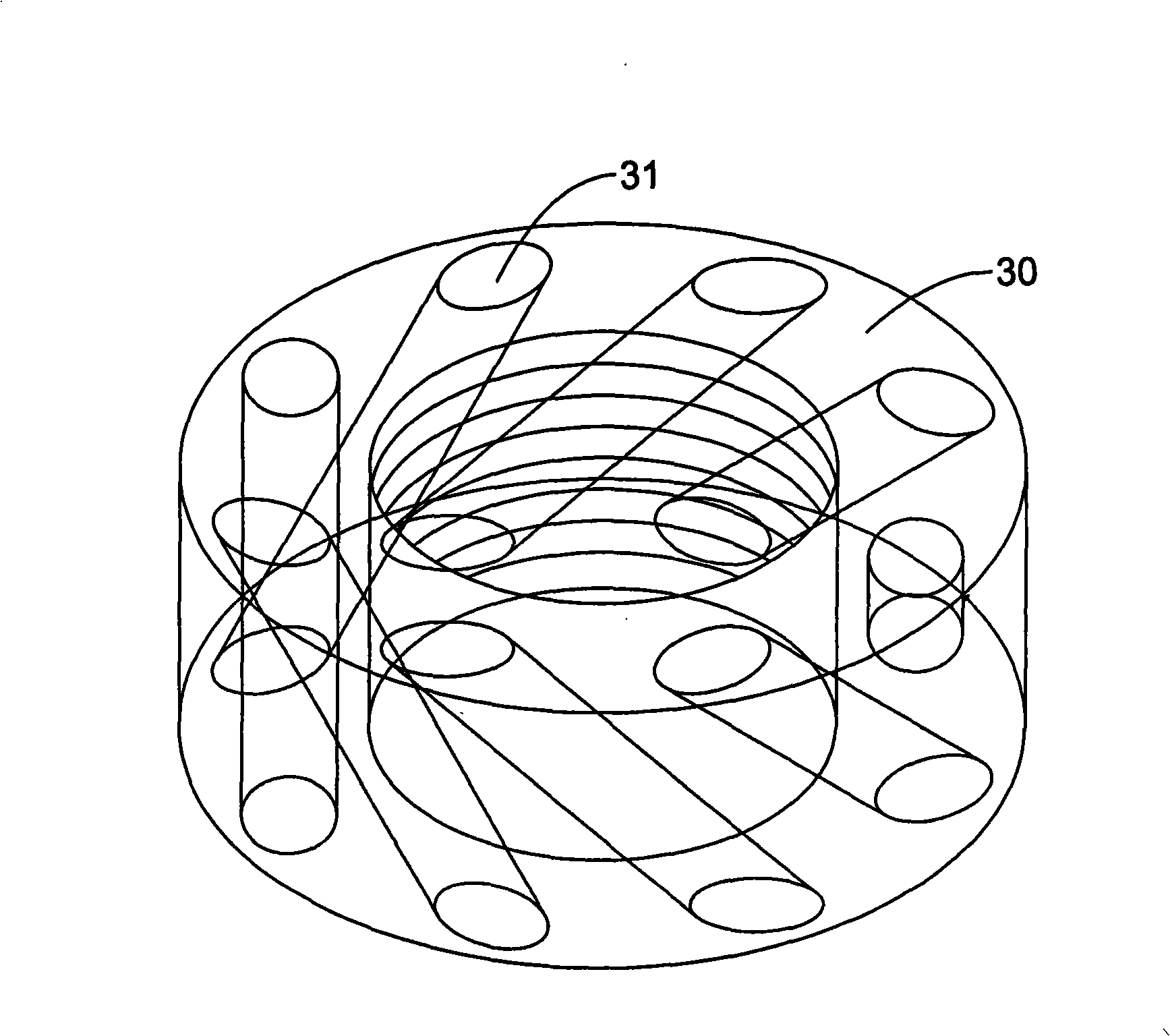

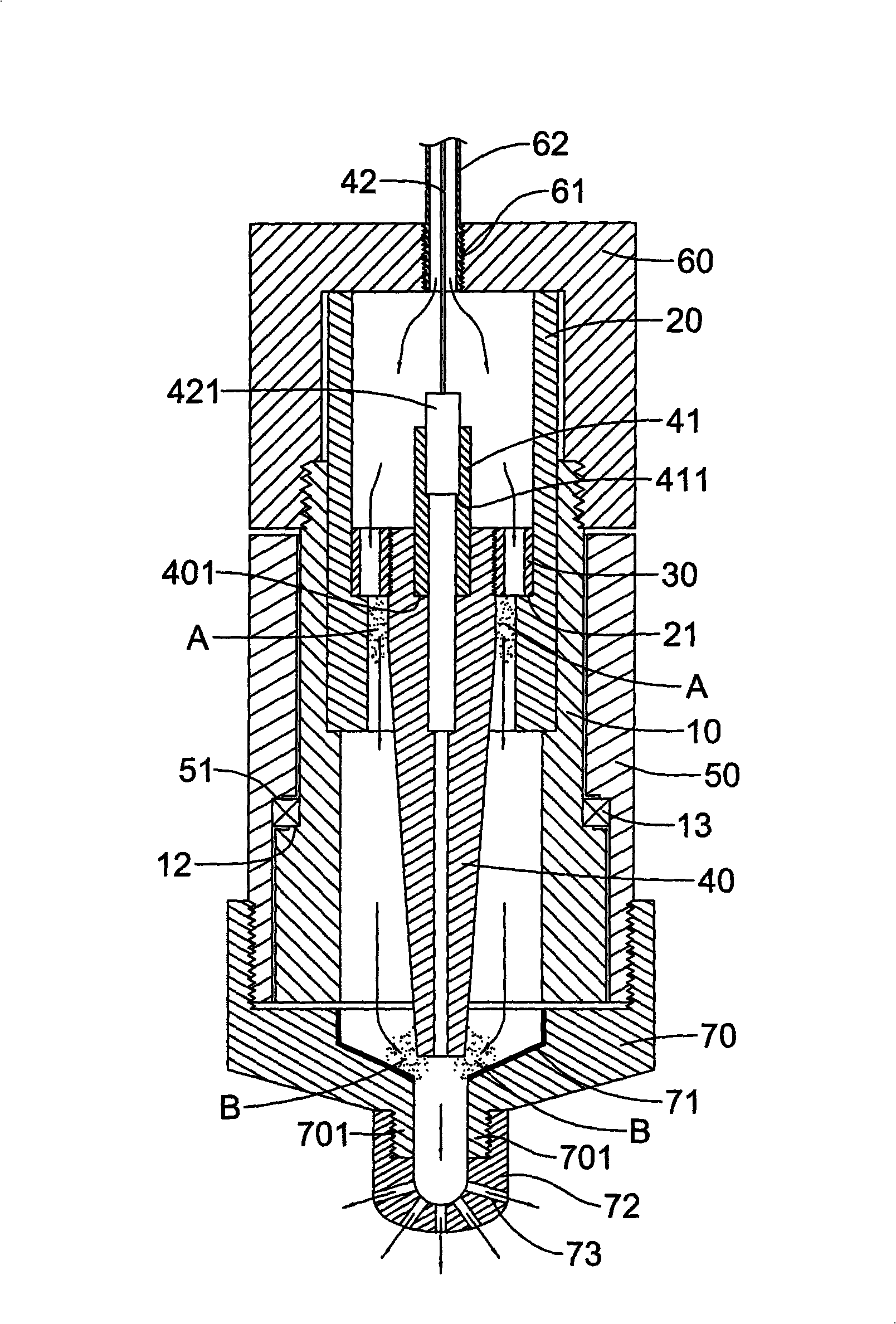

[0058] see figure 1 and figure 2 as shown, figure 1 It is a schematic cross-sectional view of the plasma jet electrode device of the present invention, figure 2 It is a three-dimensional schematic diagram of the disk in the plasma jet electrode device of the present invention. The plasma jet electrode device of the preferred embodiment of the present invention has a positioning seat 10, a ceramic tube 20 is arranged in the positioning seat 10, a disc 30 is arranged in the ceramic tube 20, and several The oblique hole 31 that runs through obli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com