Plasma processing device, plasma processing method and storage medium

A plasma and processing device technology, applied in the field of plasma processing devices, can solve labor and time-consuming problems and achieve good plasma processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

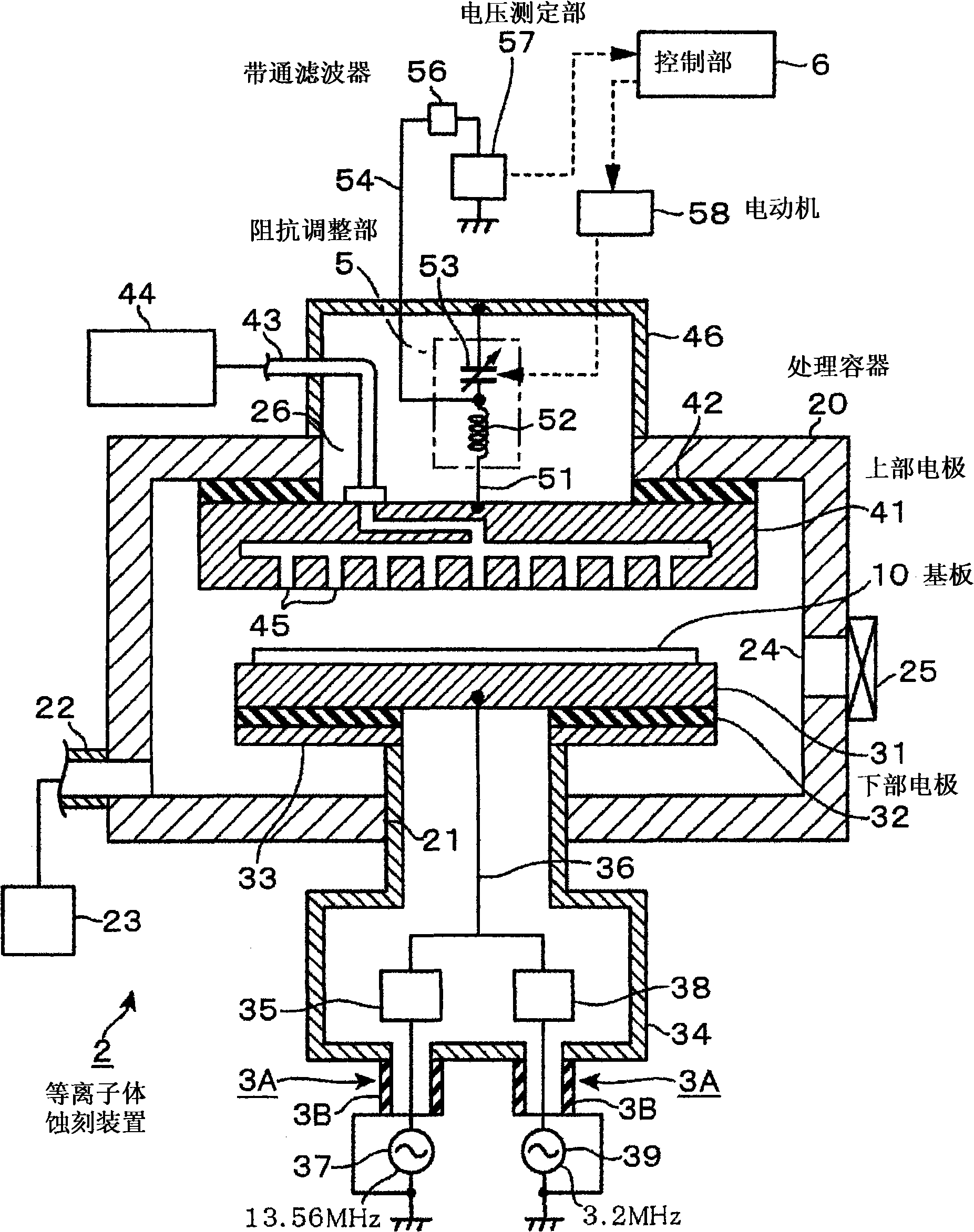

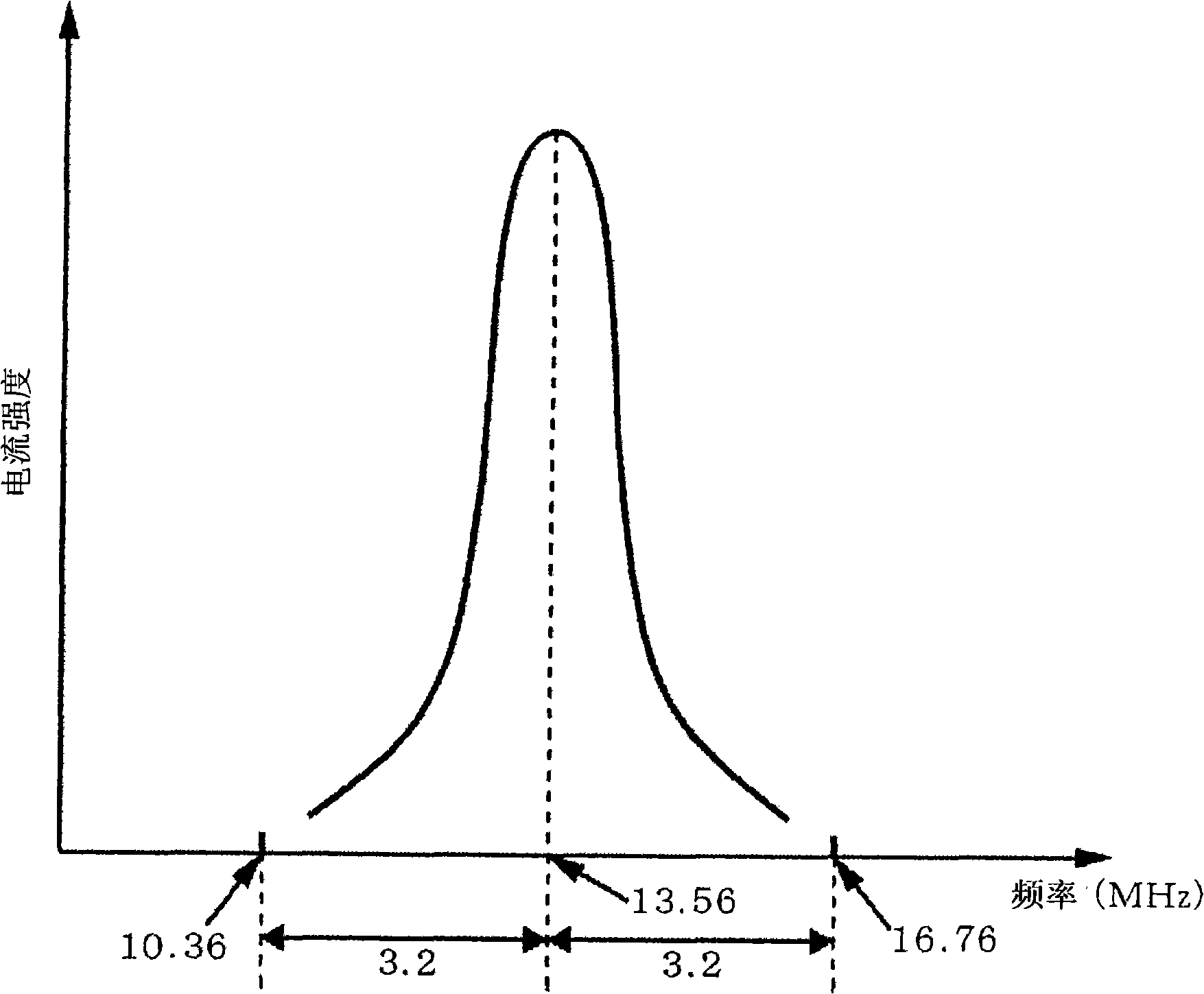

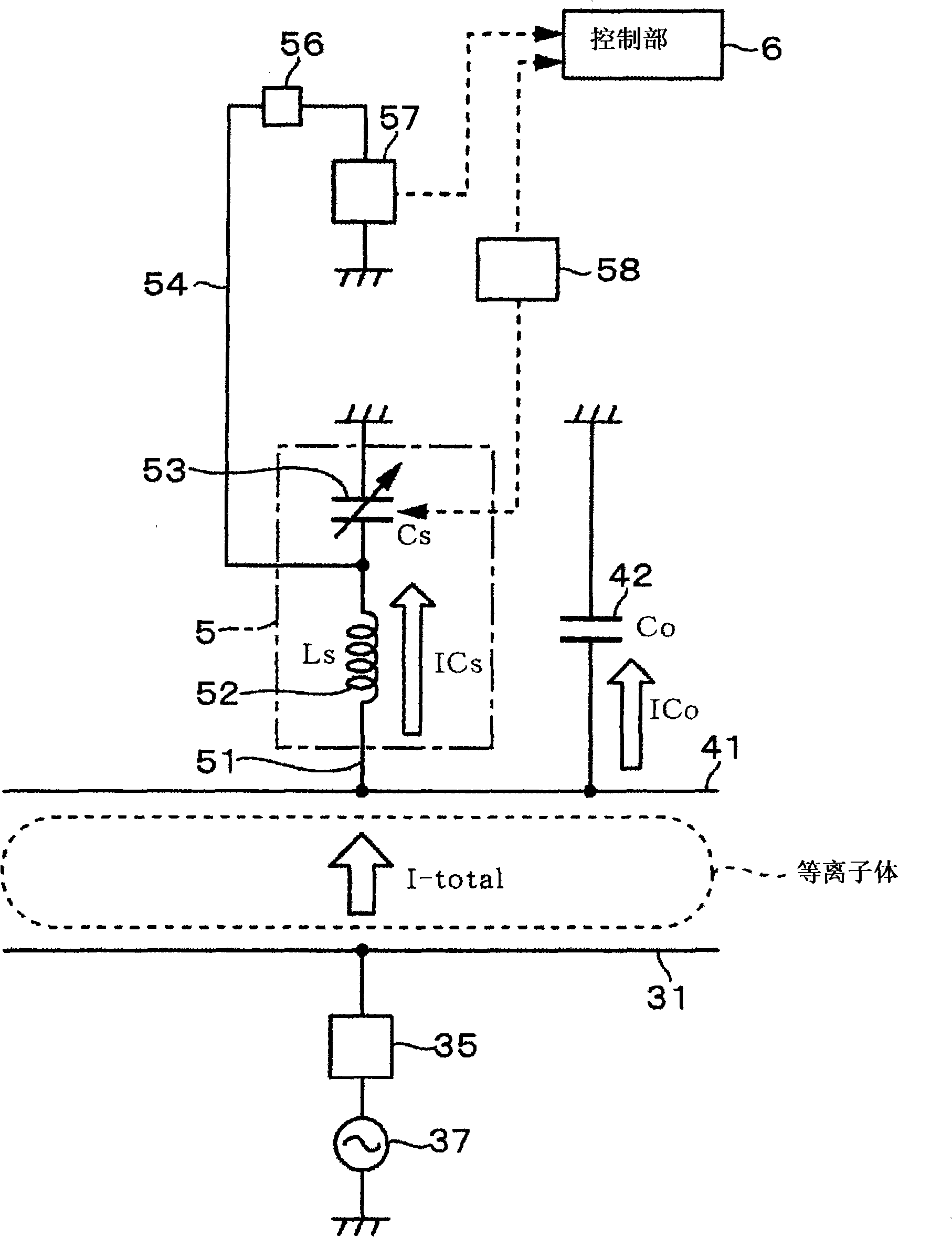

[0059] Refer below figure 1 , an embodiment in which the plasma processing apparatus of the present invention is applied to an apparatus for etching a glass substrate 10 for a liquid crystal display will be described. The plasma etching apparatus 2 has, for example, an angular tube-shaped processing container 20 made of aluminum whose surface has been anodized. A lower electrode 31 is provided at the lower center of the processing chamber 20 , and the lower electrode 31 also serves as a mounting table for placing the substrate 10 conveyed into the processing chamber 20 by a conveyance mechanism not shown. An insulator 32 is provided on the lower portion of the lower electrode 31 along the opening edge of a matching box (described later). The lower electrode 31 is sufficiently electrically floating from the processing container 20 by the insulator 32 . A matching box 34 extending downward through the opening 21 formed in the bottom wall of the processing container 20 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com