Upright post reversed type digital controlled multilated gear shaping machine

A fan-shaped gear, flip technology, applied in the direction of gear tooth manufacturing device, gear cutting machine, belt/chain/gear, etc., can solve the problems of lag, high noise, insufficient protection of coolant and oil smoke, etc., and achieve good rigidity. , The effect of easy adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The invention provides a column-turning numerically controlled sector gear shaping machine which adjusts the cutting angle by turning the column.

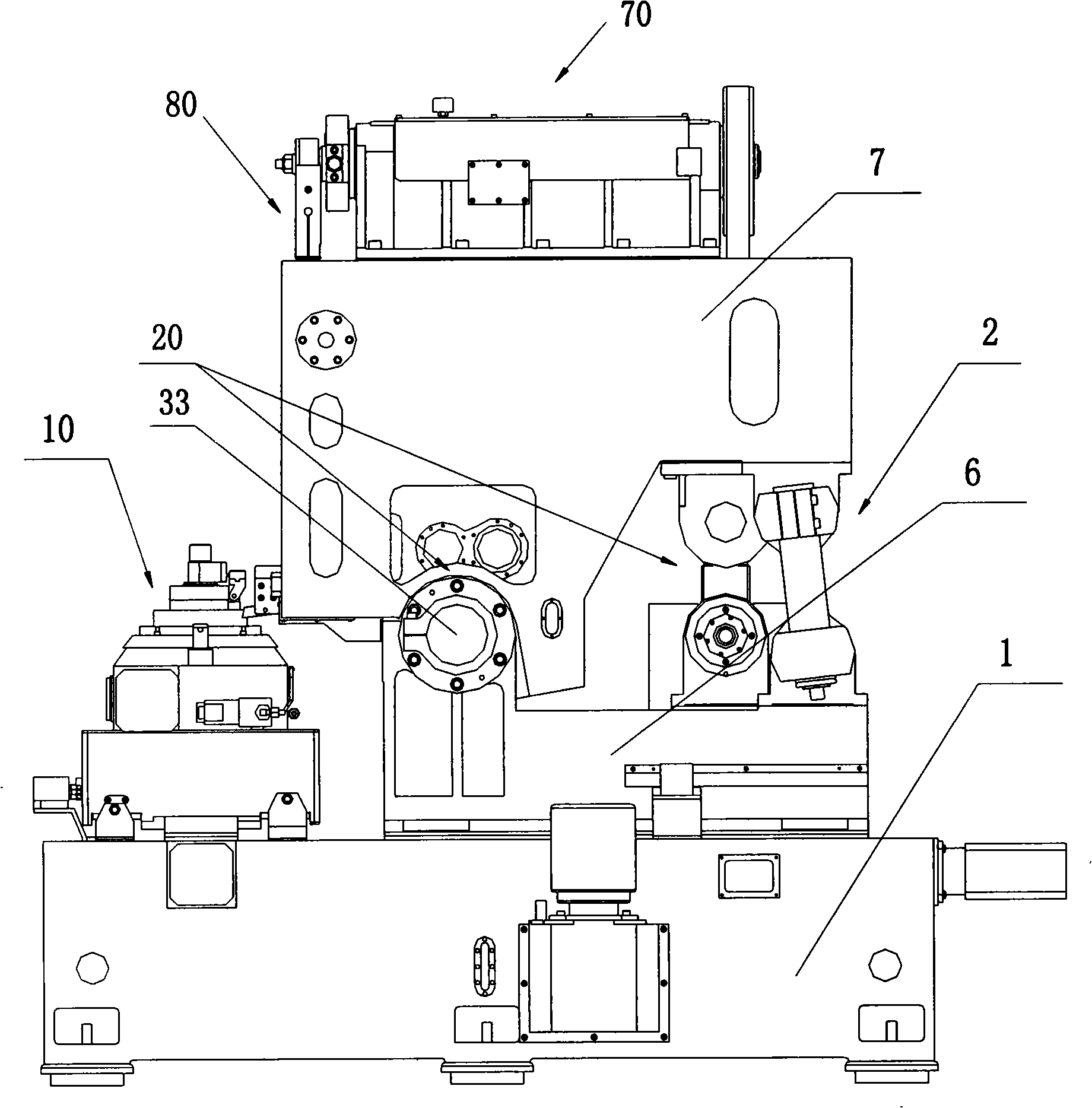

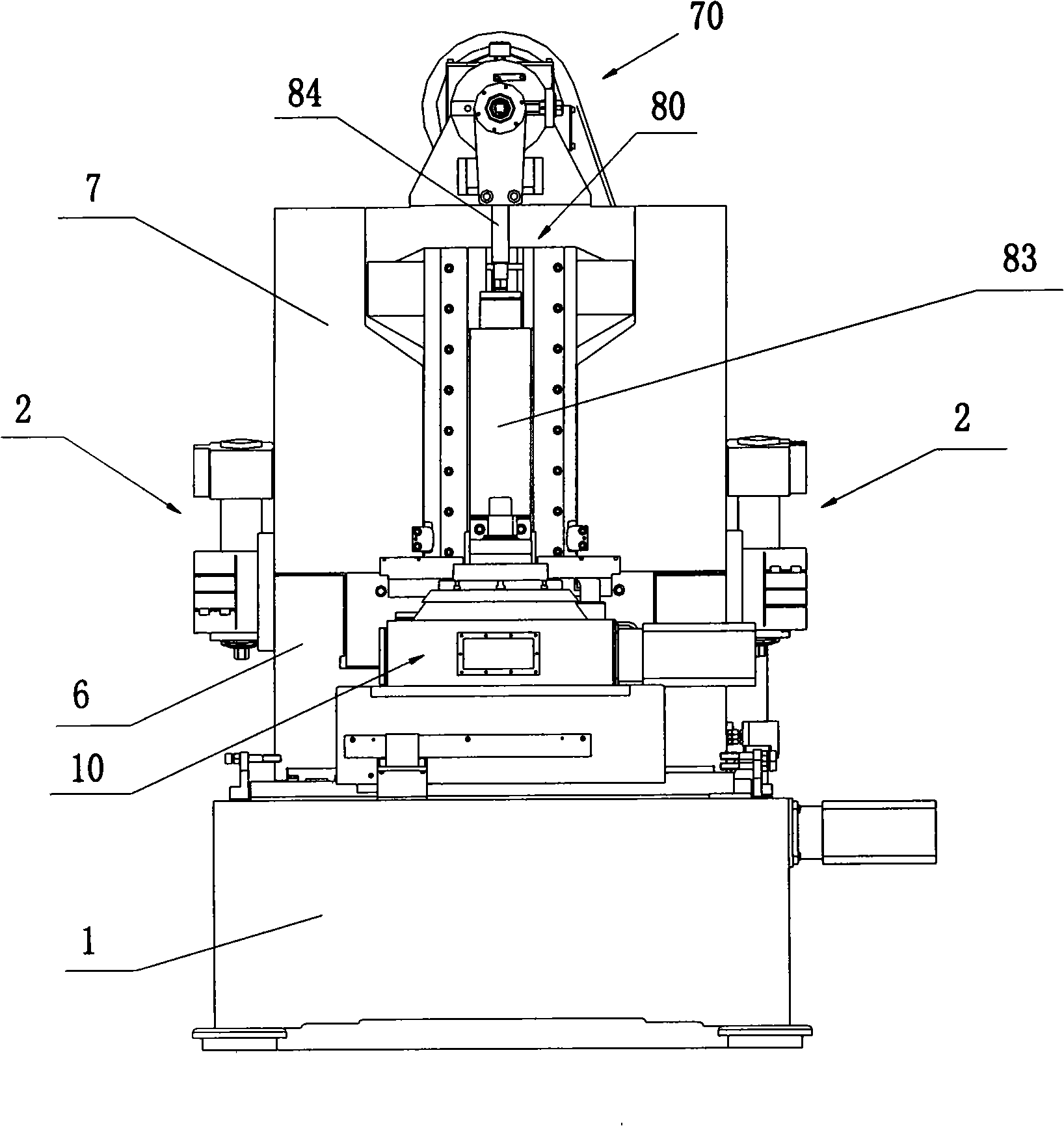

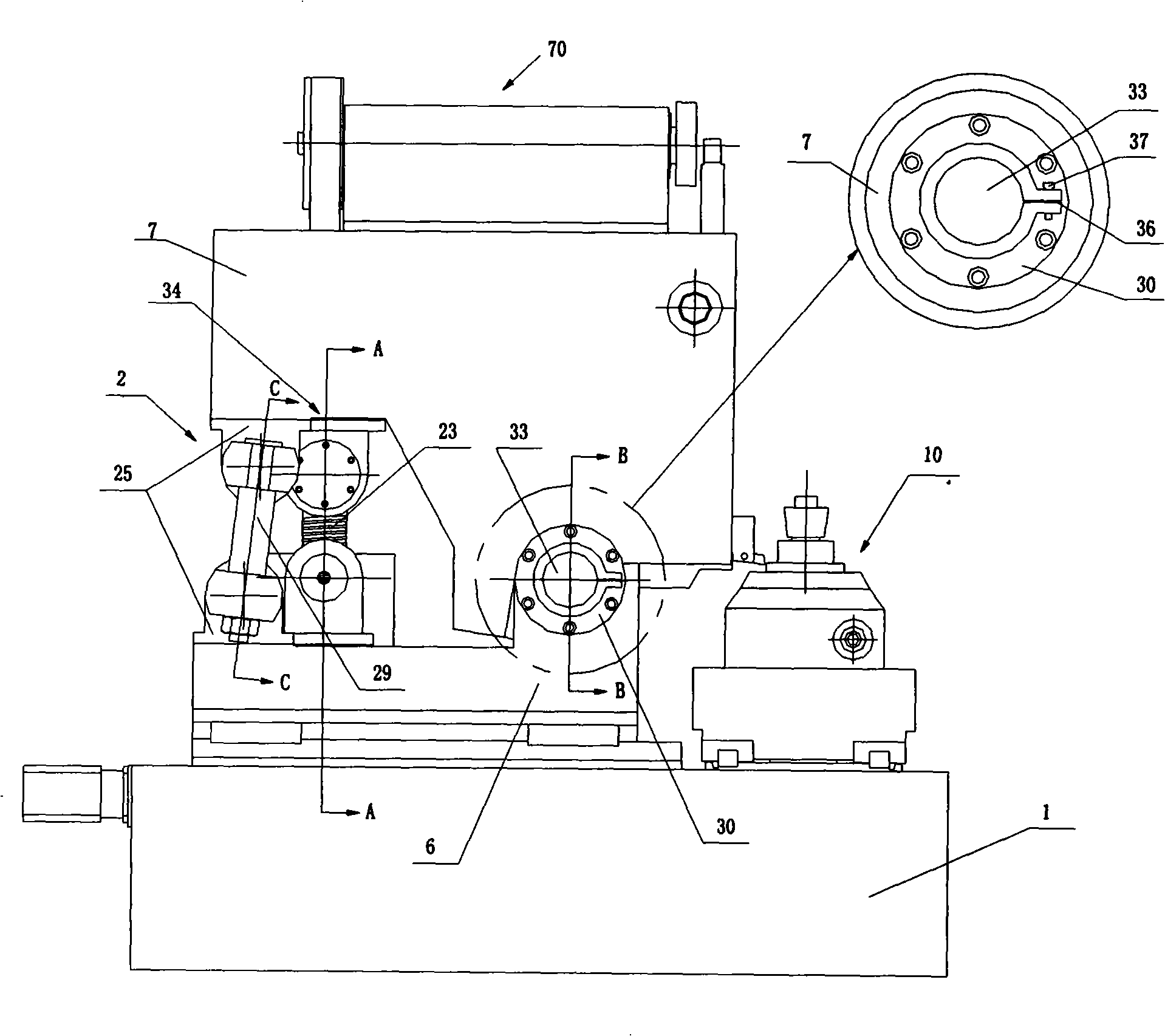

[0026] Such as Figure 1 to Figure 3 As shown, the structure of the column-turning CNC sector gear shaping machine mainly includes: a lower bed 1; a workbench 10 for lateral movement is arranged above the front of the lower bed 1; There is a middle bed 6 which moves longitudinally; a column 7 arranged on the upper part of the middle bed 6; a main driving mechanism 70 is arranged on the top of the column 7;

[0027] The present invention is provided with column overturning mechanism 20 between middle bed 6 and column 7, and this column overturning mechanism 20 is: the front part of column 7 is hinged with the rotary hinge shaft 33 that is positioned on middle bed 6, and the rear portion of column 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com