Visual system and method for gas hydrate cold storage/gas storage

A gas hydrate and cold storage technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of large supercooling, slow growth speed, long induction time, etc., achieve reliable operation, solve high-pressure rotary seal Problems, effects of increasing generation rate and gas storage/cold storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

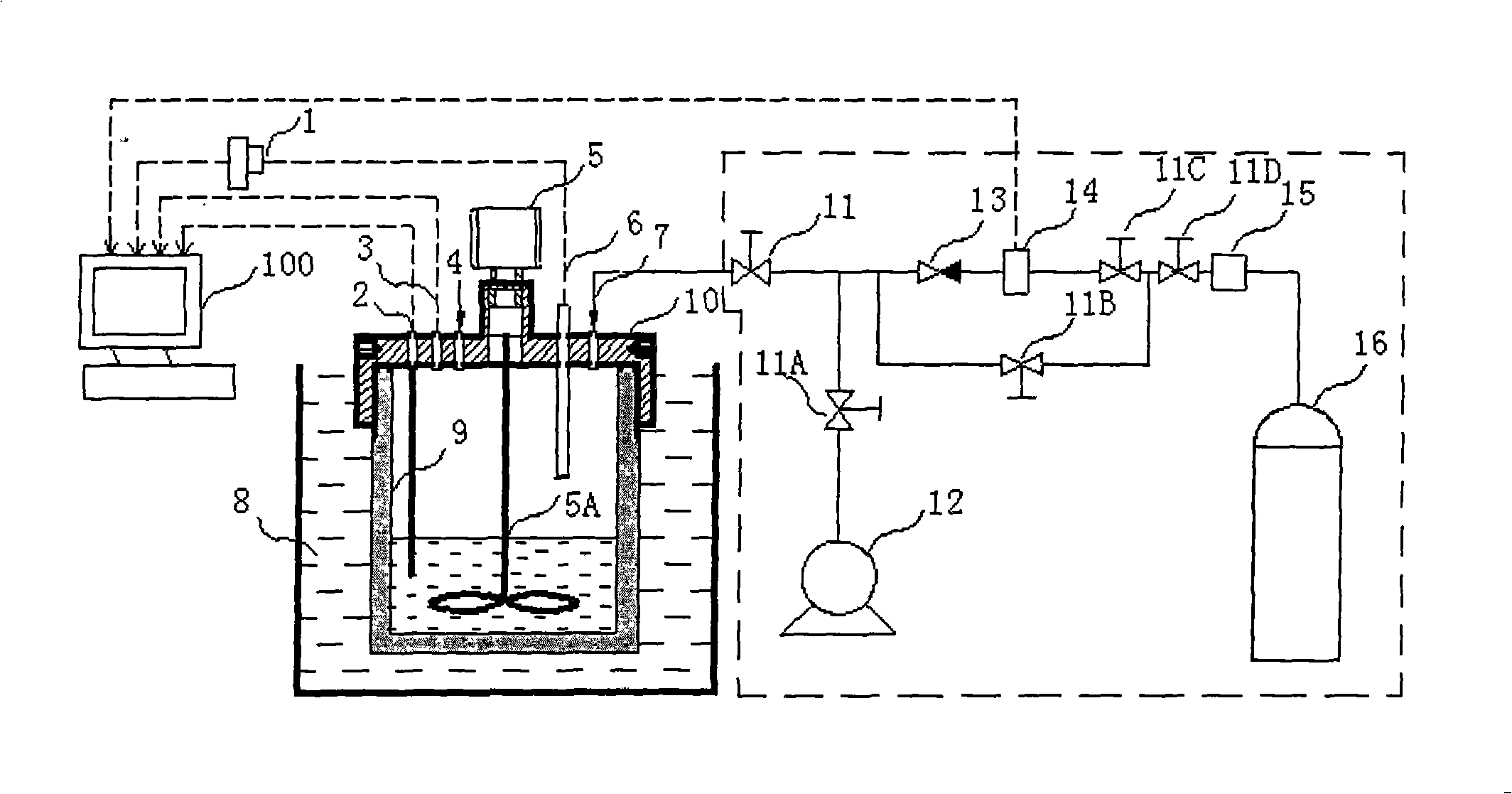

[0017] Such as figure 1 As shown, the main body of the device of the present invention is a high-pressure reaction kettle 9, and five openings are designed on the end cover 10 of the reaction kettle 9, which are respectively a temperature sensor installation thread port 2 and a pressure sensor installation thread port 3; a liquid inlet 4; The air inlet 7 and an electronic endoscope tube are installed with a threaded port 6; the permanent magnet stirring motor 5 is fixedly installed on the end cover 10 of the reaction kettle 9, is located in the middle of the reaction kettle 9, and the lower end is connected with the stirring blade 5A, and the magnetic coupling is used for stirring Technology, the static seal is used instead of the dynamic seal, which solves the problem of high pressure leakage. The electronic camera system 1 can be connected with the high-pressure reaction kettle 9 through the electronic endoscope tube installation screw port 6, and the internal reaction situa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com