Three-phase cyclone separator cleaning treatment system for oil-contaminated water

A cyclone separator and flow separation technology, which is applied in the direction of centrifugal separation water/sewage treatment, flocculation/sedimentation water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problem of long sewage treatment process and water purification Poor effect, large equipment footprint and other problems, to achieve the effect of short purification treatment time, reduce environmental pressure, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

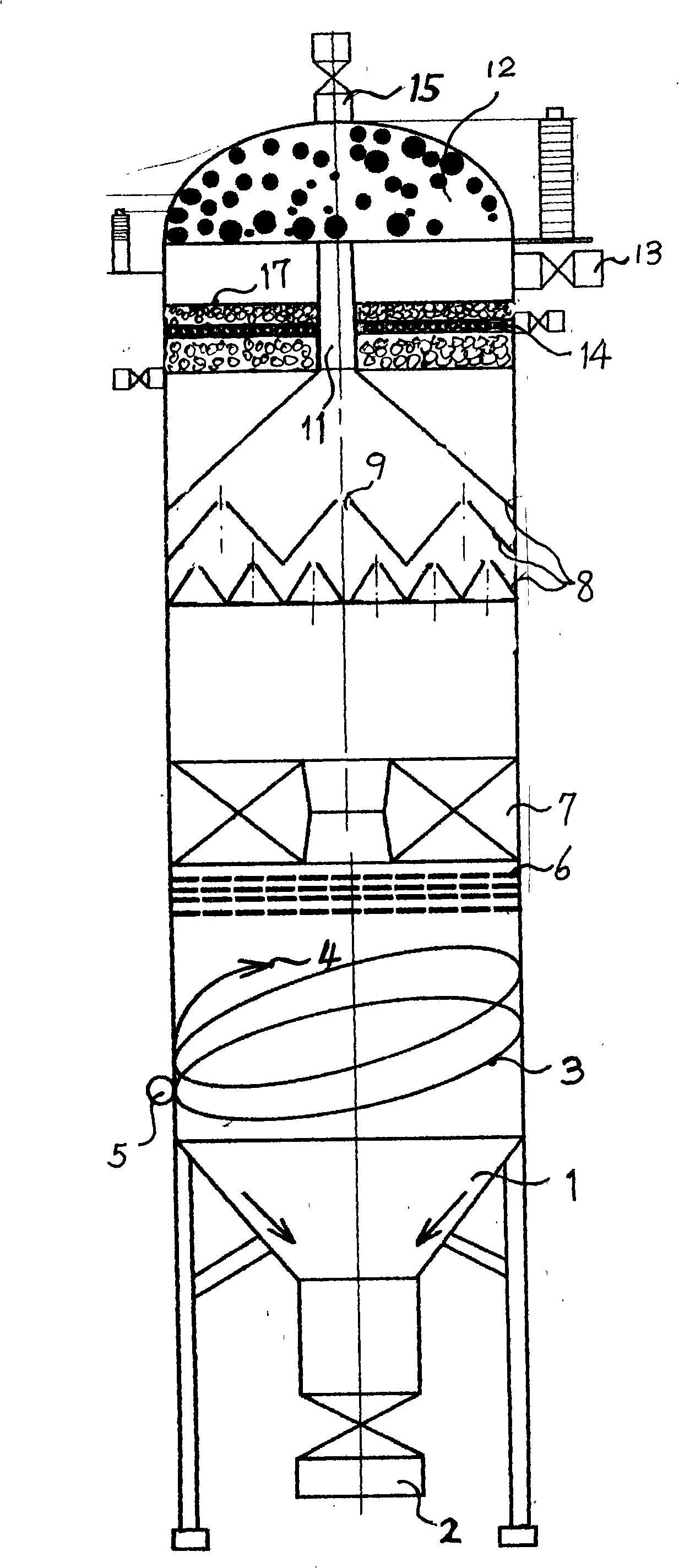

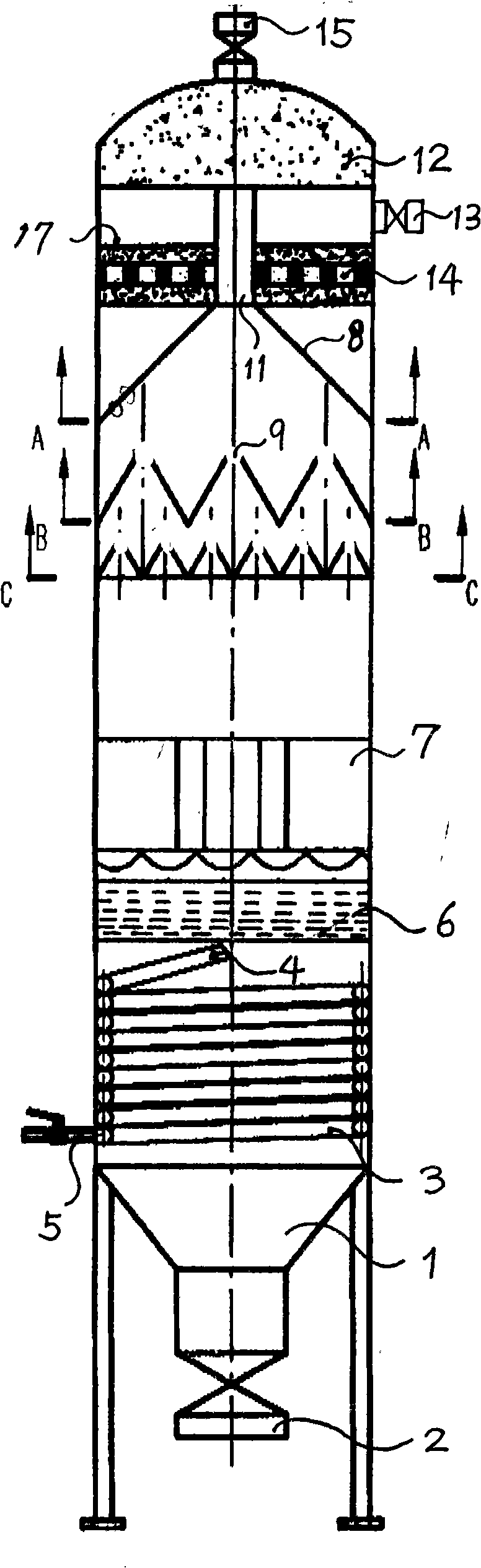

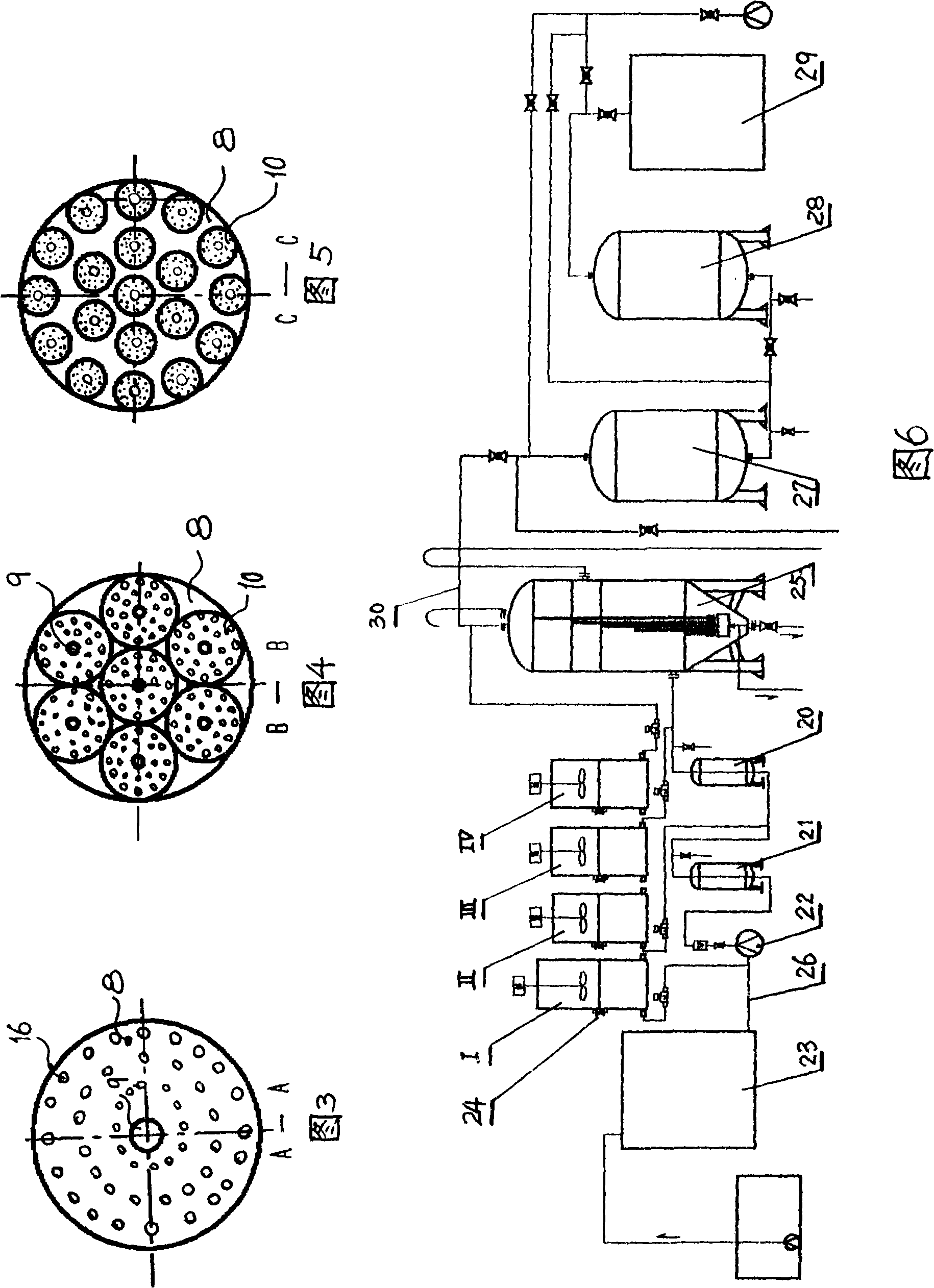

[0015] As shown in the figure, the three-phase cyclone separator provided by the present invention has an inverted conical sludge collector 1 at the bottom of the tank, and a settled sludge discharge port 2 at the bottom; The body is provided with a swirling flow settlement area, an inclined tube settlement area and a filter layer area in sequence upwards. The swirling flow settlement area is mainly provided with a swirling flow nozzle 3, the oily sewage water inlet 5 of the swirling flow nozzle 3 is arranged along the tangential direction of the tank body, and the upper end of the swirling flow nozzle 3 is a water outlet nozzle 4; in the structure of this embodiment Among them, in order to improve the swirl settlement effect, the swirl nozzle adopts a variable-diameter swirl nozzle structure, that is, the diameter of the water inlet is relatively large, and the diameter of the pipe is gradually reduced to the small-diameter outlet nozzle. After the oily sewage enters the swir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com