Preparation of acrylic acid

A technology of acrylic acid and lactic acid, which is applied in the chemical industry to achieve the effects of low production cost, low environmental pollution and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

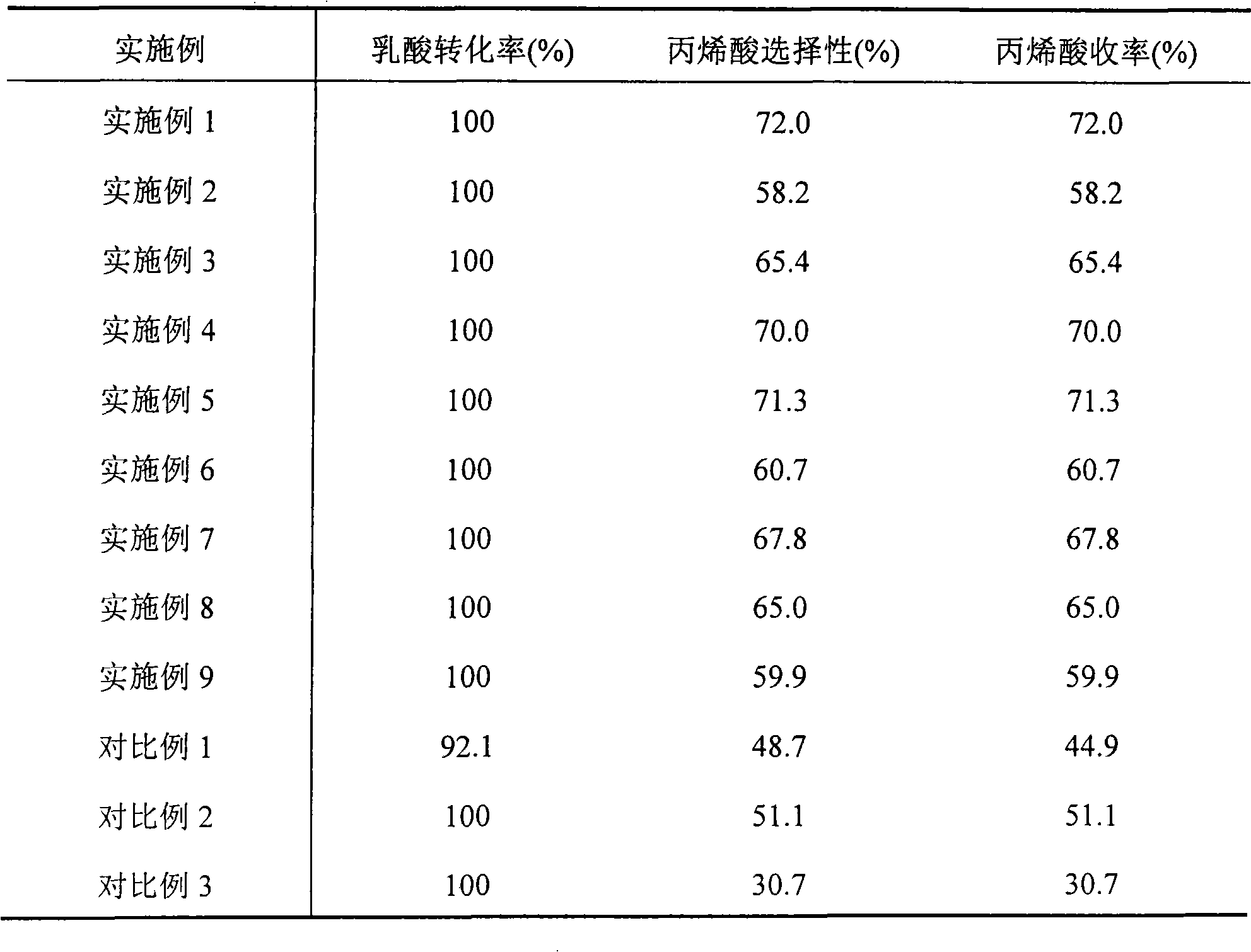

[0021] Put 1.2g of 30-50 mesh NaY catalyst into the constant temperature section of the tubular fixed-bed reactor, and fill the rest with quartz sand. After the system checks the seal, when the volumetric space velocity is 3h -1 N 2 The temperature of the catalytic bed was raised to 400°C under the gas flow rate, and the 10% ammonia water was mixed with a volume space velocity of 1.5h -1 After feeding the catalyst for 2 hours, keep the high temperature for 0.5 hours, then lower the temperature to 350°C, then inject 38% lactic acid solution into the system, and react through the catalytic bed after gasification. The reaction mixture is cooled by an ice-water bath and separated from gas and liquid. , the gas was evacuated, and the liquid collected after 1.5 hours of reaction was sampled for analysis, and the results are shown in Table 1.

Embodiment 2

[0023] Put 1.2g of 30-50 mesh NaY catalyst into the constant temperature section of the tubular fixed-bed reactor, and fill the rest with quartz sand. After the system checks the seal, when the volumetric space velocity is 3h -1 N 2 Under the gas flow rate, the temperature of the catalytic bed layer was raised to 500°C, and 3% ammonia water was added at a volumetric space velocity of 2h -1 After feeding the catalyst for 2 hours, keep the high temperature for 0.5 hours, then lower the temperature to 300°C, then inject 18% lactic acid solution into the system, and react through the catalytic bed after gasification. The reaction mixture is cooled by an ice-water bath and separated from gas and liquid. , the gas was evacuated, and the liquid sample collected after 1.5 hours of reaction was analyzed, and the results are shown in Table 1.

Embodiment 3

[0025] Put 1.2g of 30-50 mesh NaY catalyst into the constant temperature section of the tubular fixed-bed reactor, and fill the rest with quartz sand. After the system checks the seal, when the volumetric space velocity is 4h -1 N 2 Under the gas flow rate, the temperature of the catalytic bed layer was raised to 600°C, and 30% ammonia water was added at a volumetric space velocity of 1h -1 After feeding the catalyst for 2 hours, keep the high temperature for 0.5 hours, then lower the temperature to 420°C, then inject 38% lactic acid solution into the system, and react through the catalytic bed after gasification. The reaction mixture is cooled by an ice-water bath and separated from gas and liquid. , the gas was evacuated, and the liquid sample collected after 1.5 hours of reaction was analyzed, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com