Hydrothermally stable microporous molecular sieve catalyst and preparation method thereof

一种水热稳定、分子筛的技术,应用在分子筛催化剂、化学仪器和方法、物理/化学过程催化剂等方向,能够解决酸位损失、催化性能下降等问题,达到反应简单、保持催化活性、降低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

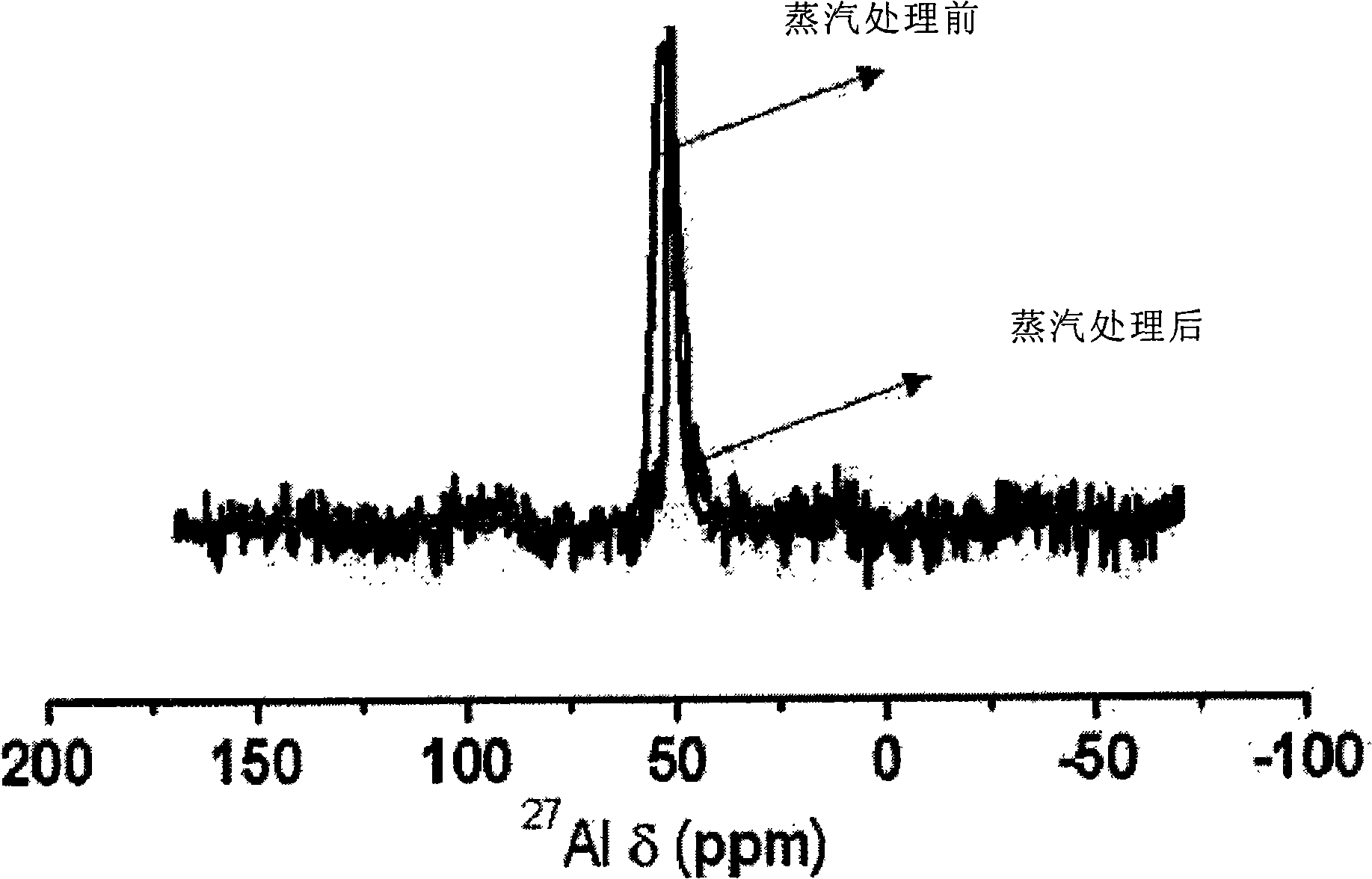

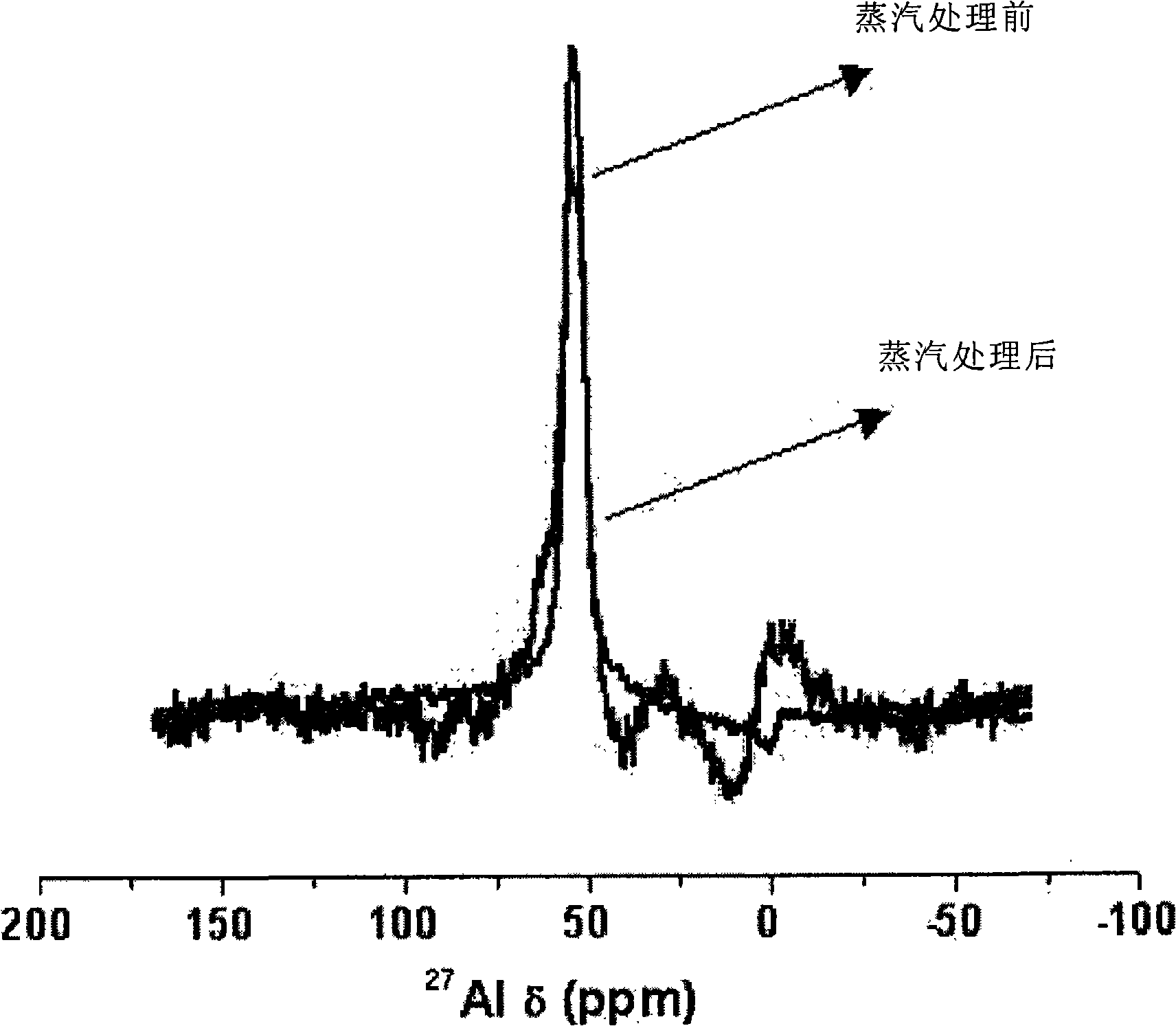

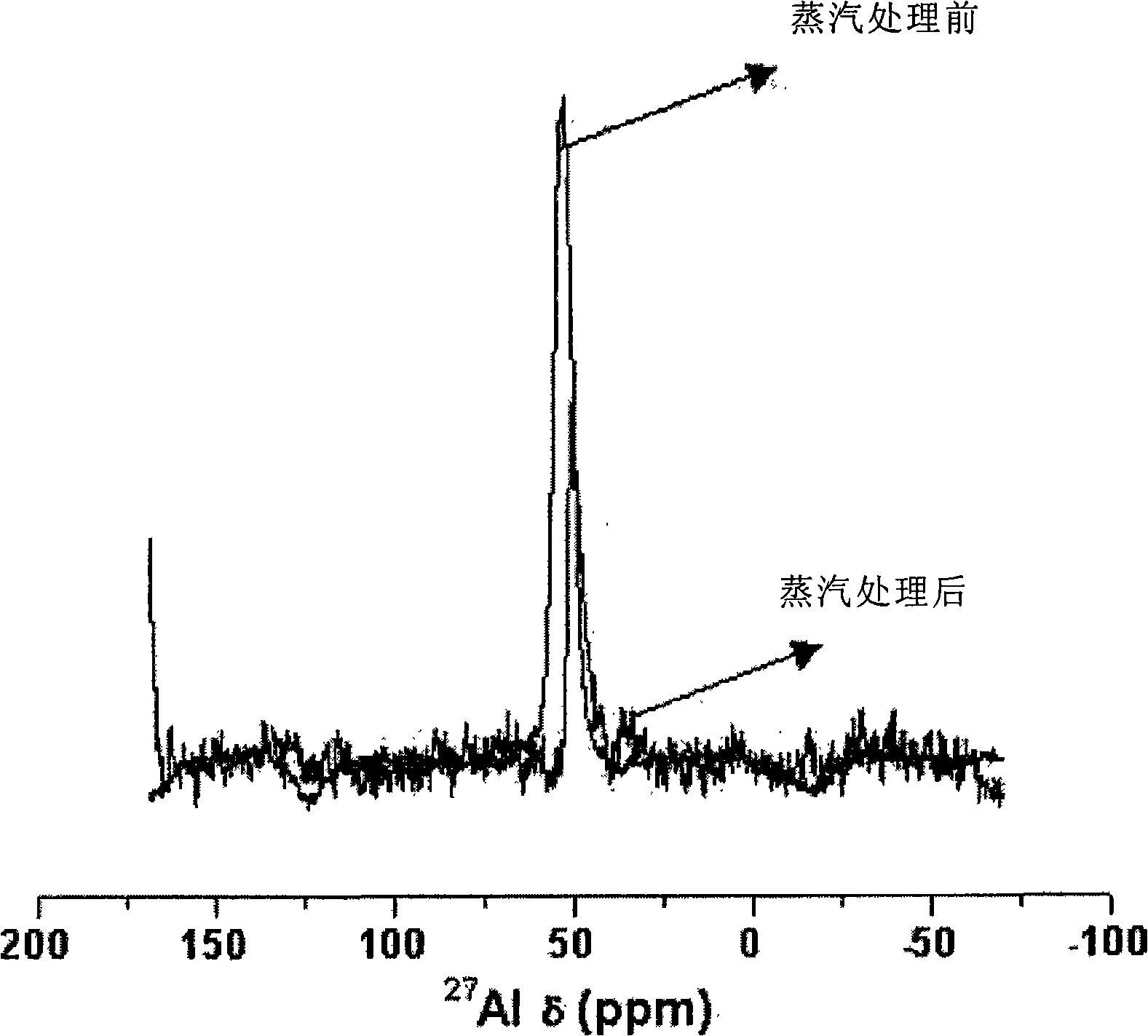

[0068] Although the description of the preparation of the molecular sieve catalyst is not limited to a certain theory, it is believed that, as the following reaction scheme figure 1 and 2As shown, the modification of -Si-OH-Al-groups forming molecular sieves with phosphate compound / metal composite structure is to compress them with zeolite protons so that the ≡P=O groups stabilize the unstable Al while using The metal stabilizes the two -OH groups, so that the skeleton structure can be maintained relatively stably even in an atmosphere of high temperature and high humidity:

[0069] [Reaction scheme 1]

[0070]

[0071] [Reaction scheme 2]

[0072]

[0073] The method for preparing the catalyst described in the present invention can be broadly divided into two methods, which include the step of removing the water contained in the above-mentioned raw material mixture through a selective evaporation process to collect a solid product.

[0074] The preparation method of...

Embodiment 1

[0093] (1) 9.58g concentrated phosphoric acid (85%H 3 PO 4 ) was dissolved in 200 mL of distilled water. To this solution was slowly added 3.35 g of MgO and stirred for about 20 minutes. Next, the solution was stirred at about 40°C for about 1 hour, and then at about 60°C until the water was completely evaporated. The resulting solid product was washed, filtered and isolated.

[0094] (2) 1.94 g of HZSM-5 (Zeolyst) with a Si / Al molar ratio of 25 and 0.06 g of the solid product prepared in step (1) were added to 200 mL of distilled water. The mixed solution was stirred at 50-60° C. for about 5 hours, and then the stirred solution was vacuum filtered, washed and separated, thus preparing the Mg-HPO-HZSM-5 catalyst.

Embodiment 2

[0096] (1) 19.68g concentrated phosphoric acid (85%H3 PO 4 ) was dissolved in 100 mL of distilled water. To this solution was slowly added 4.78 g of Mg(OH) 2 , stirring for about 20 minutes. Next, the solution was stirred at about 40°C for about 1 hour, and then at about 60°C until the water was completely evaporated. The resulting solid product was washed, filtered and isolated.

[0097] (2) 1.94 g of HZSM-5 (Zeolyst) with a Si / Al molar ratio of 25 and 0.06 g of the solid product prepared in step (1) were added to 100 mL of distilled water. The mixed solution was stirred at 50-60°C for about 5 hours, and then the stirred solution was vacuum filtered, washed and separated, thus preparing Mg-H 2 PO 4 - HZSM-5 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com