Improvements to wankel and similar rotary engines

A rotary engine, engine technology, applied in combustion engine, machine/engine, combined engine, etc., can solve problems such as engine speed limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099]The present invention is a novel rotary engine construction having at least one rotor and at least one rotating combustor fluid control device (CCFC) whose rotation is synchronized with the rotation of each rotor. Two stationary buffer seals are located at both ends of the short axis of the rotor housing and divide the latter into two separate spaces, a first intake and compression chamber and a second expansion and exhaust chamber downstream of the first space. Each CCFC receives compressed oxygen-containing fluid from the intake chamber, injects fuel into the compressed fluid, ignites the air-fuel mixture, and delivers combustion products to the expansion chamber.

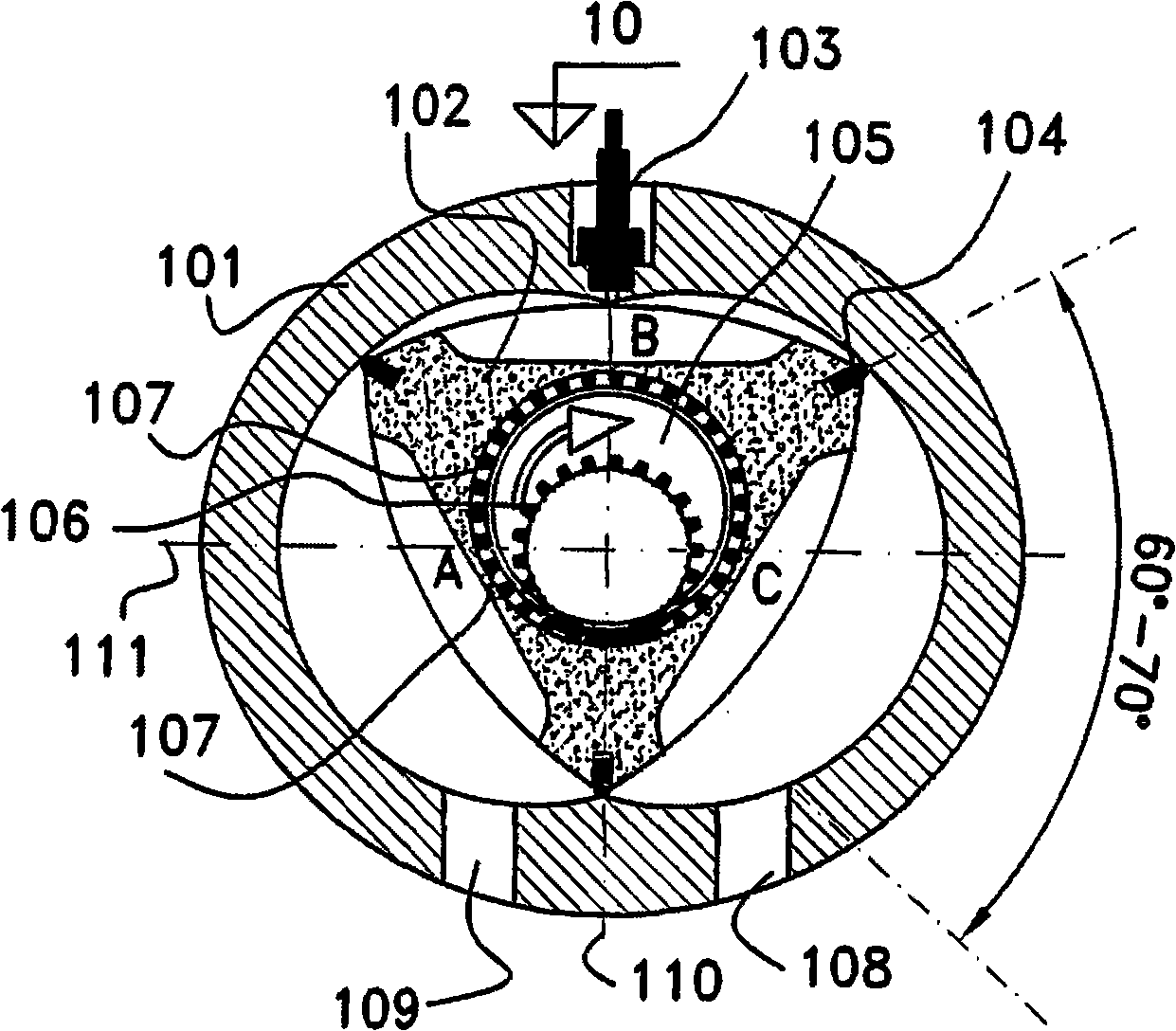

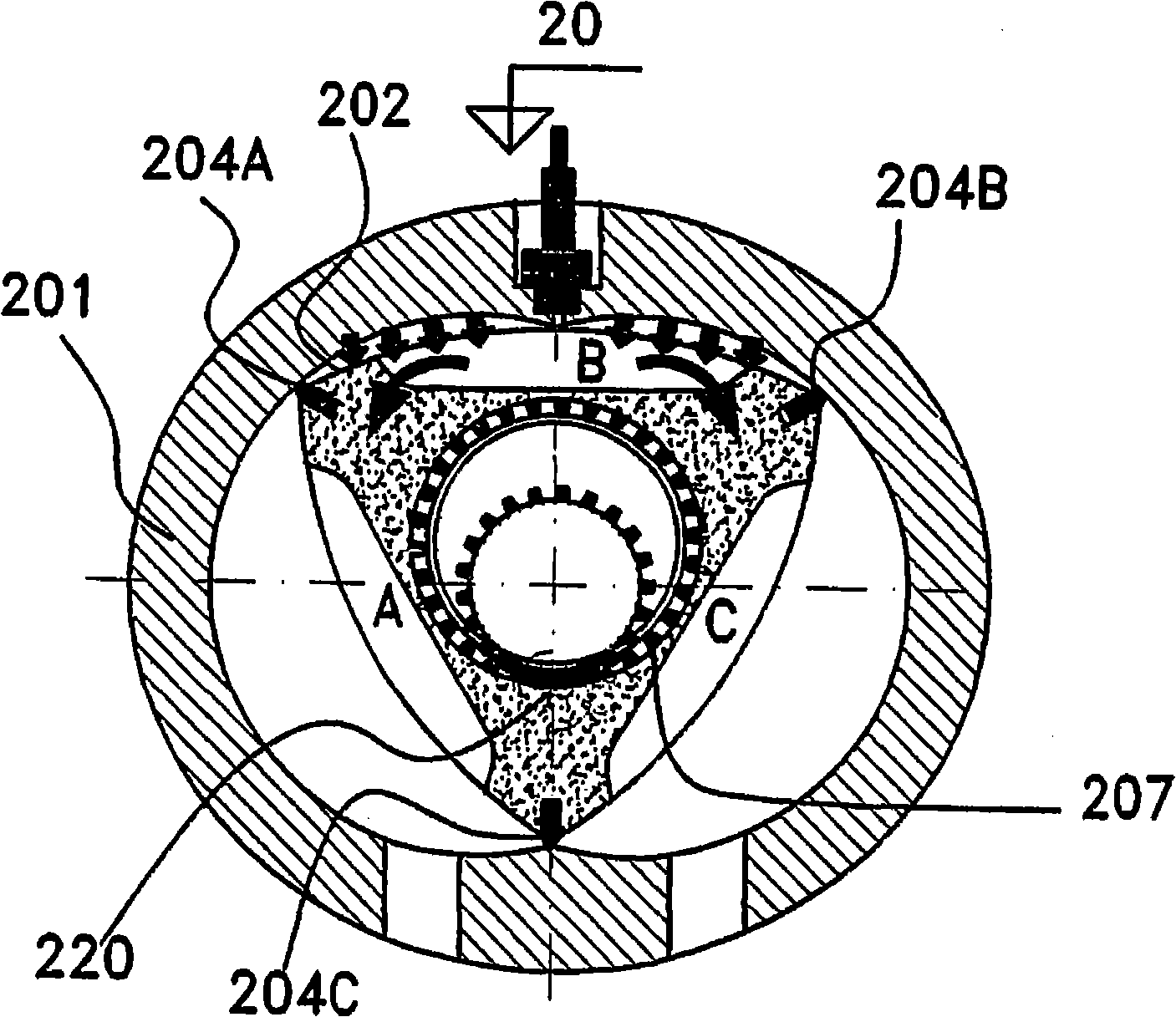

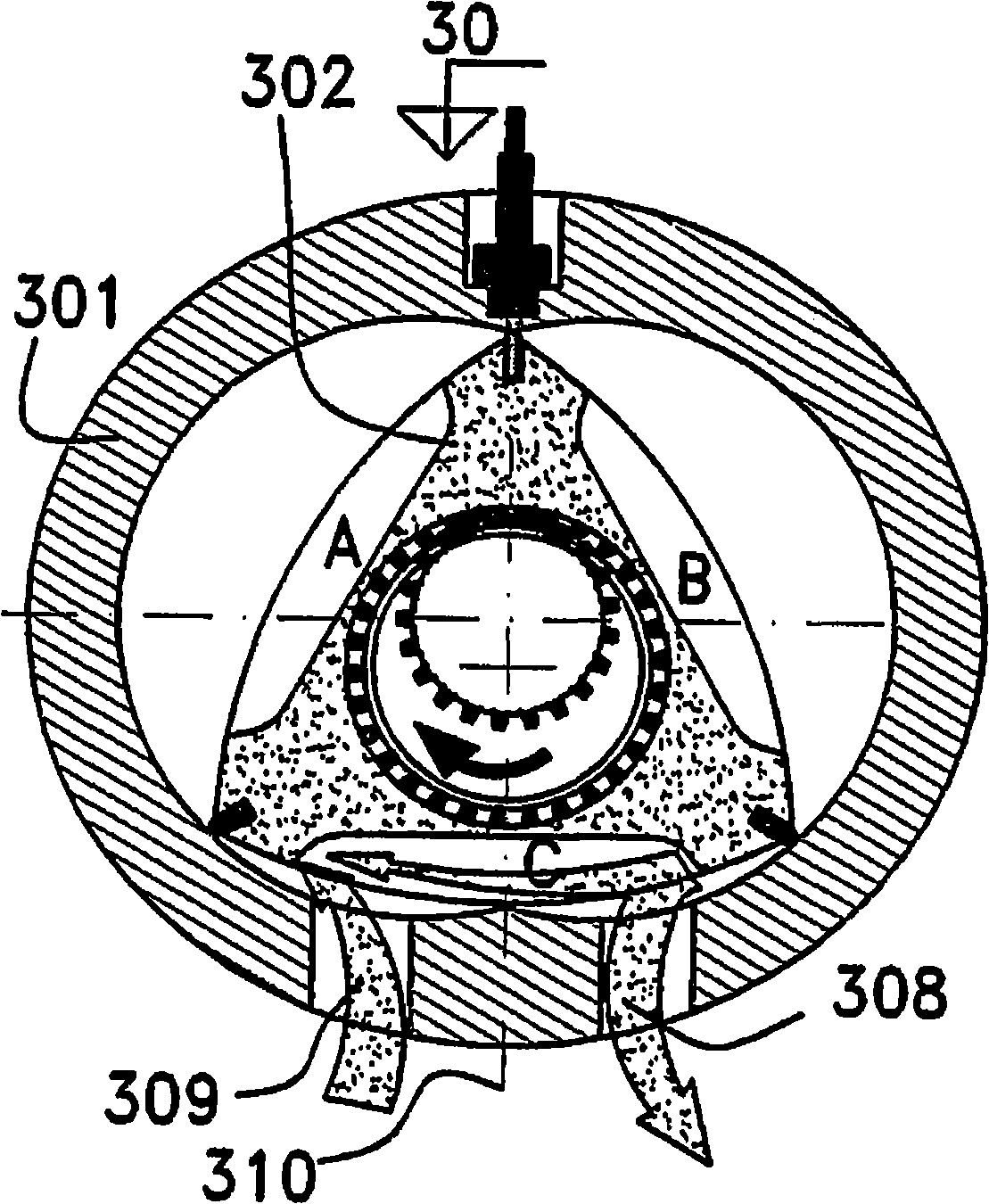

[0100] To understand the utility of the engine structure of the present invention, first see Figure 1-3 , which shows several drawbacks of prior art Wankelfa rotary engines.

[0101] figure 1 There is shown a typical prior art Wankel rotary engine, generally indicated by reference numeral 10, comprising:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com