Split pressure bearing type solar water heater

A solar water heater, pressure-bearing technology, applied to solar collectors, solar collectors using working fluid, solar thermal energy, etc., can solve problems such as slow start-up speed, affecting heat exchange, and excessive water volume in vacuum collector tubes , to reduce the overall thickness and achieve the effect of efficient heat collection and heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The present invention will be further described in detail below in conjunction with the accompanying drawings.

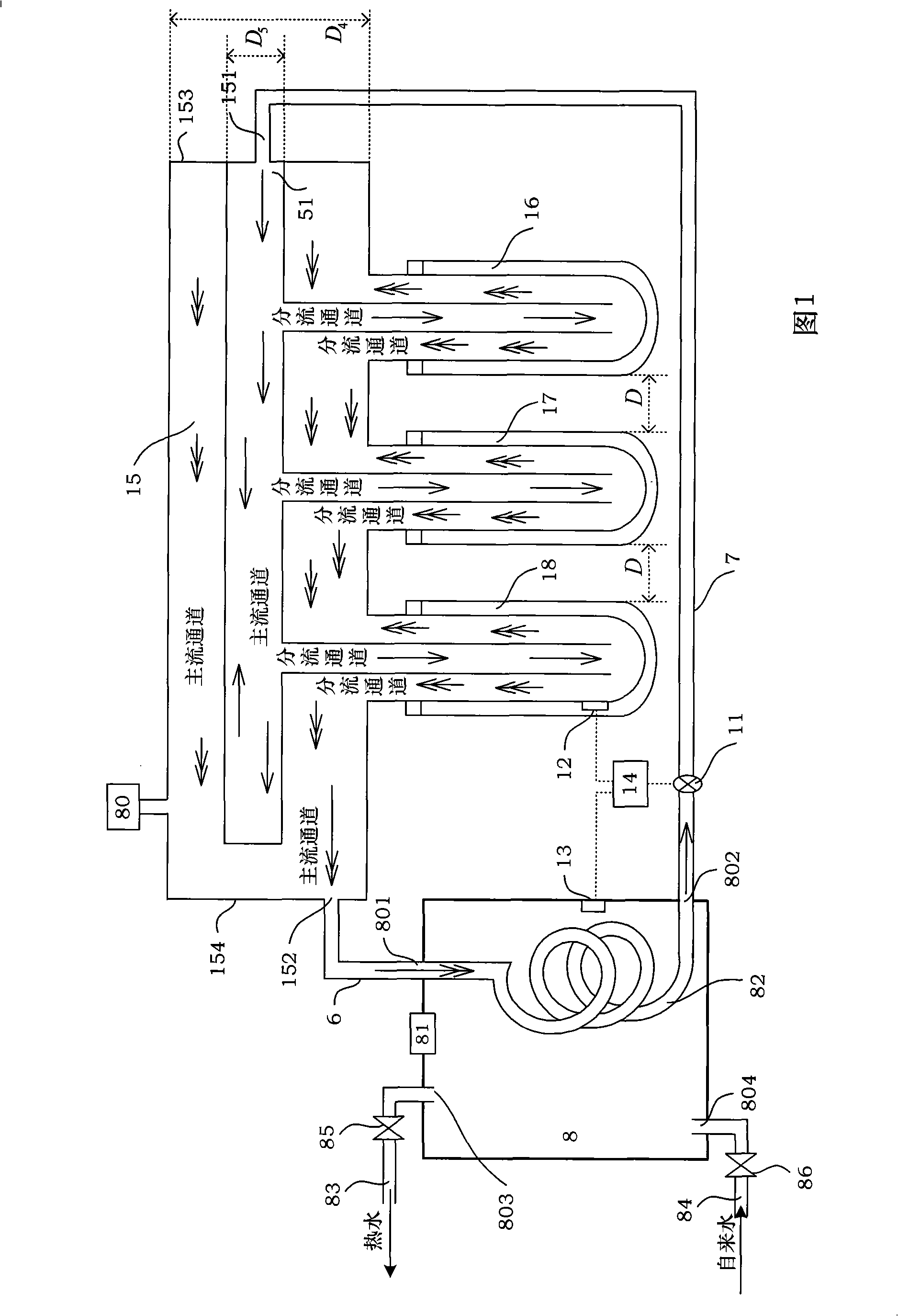

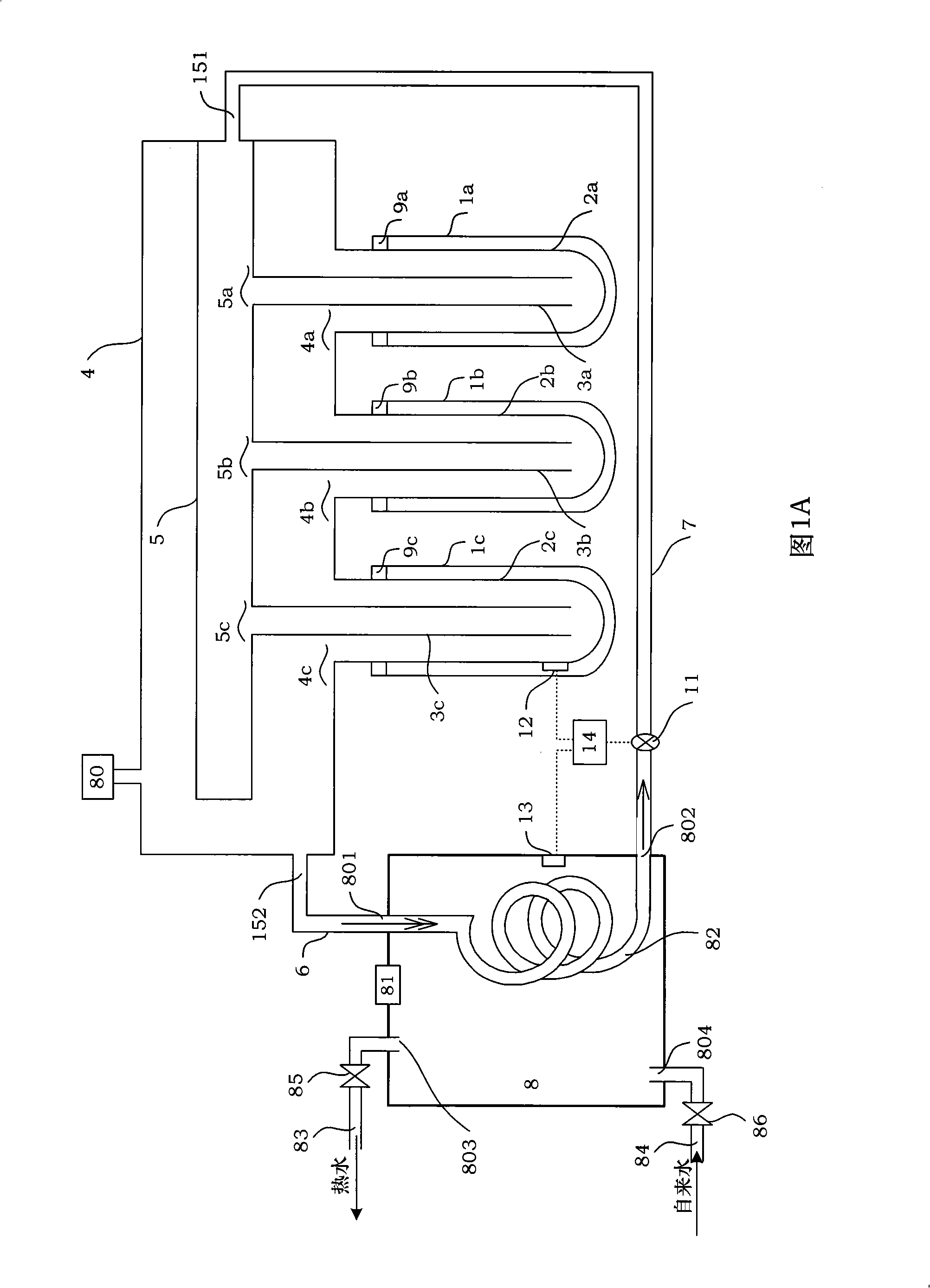

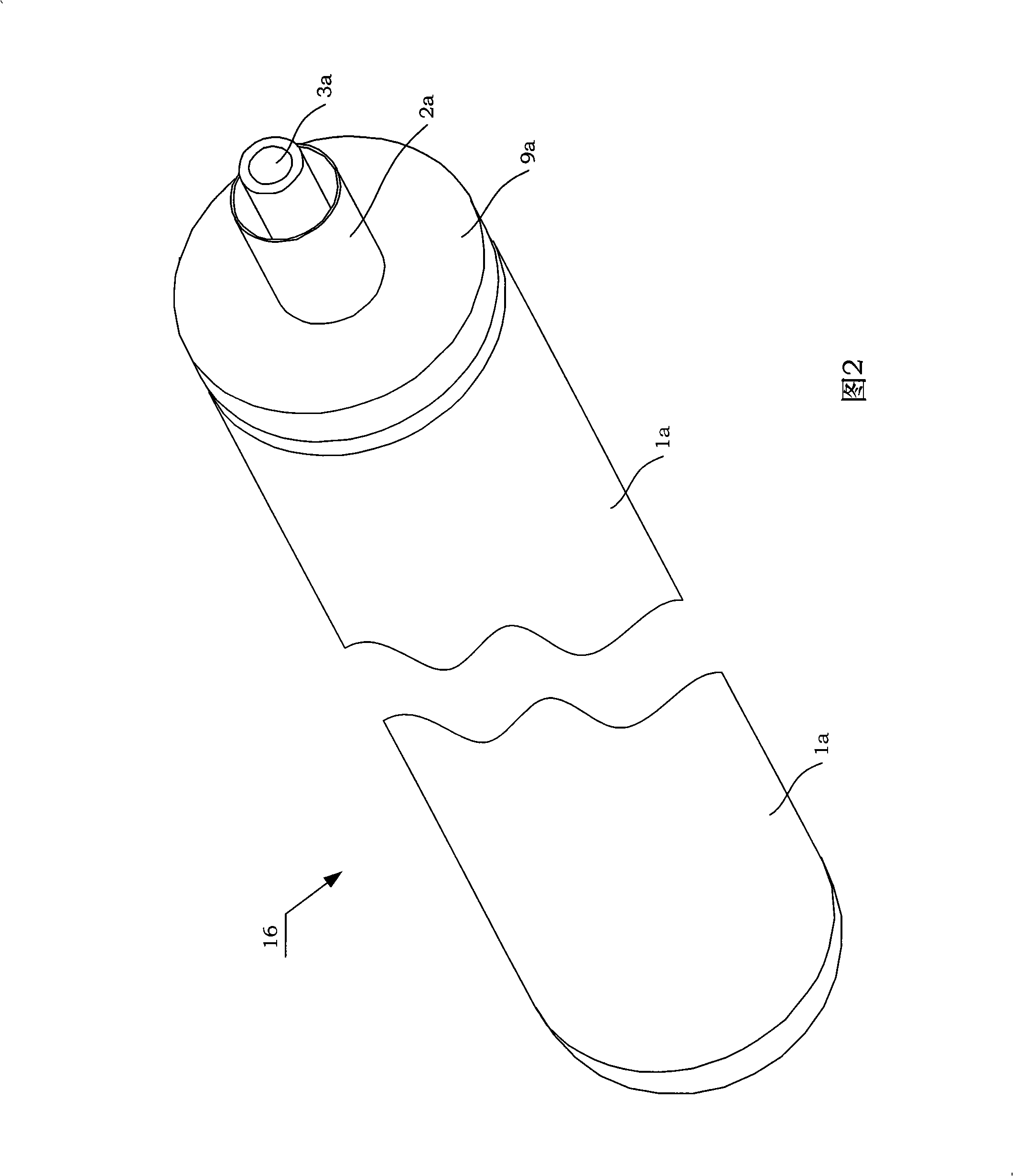

[0042] Referring to Fig. 1 and shown in Fig. 1A, the split pressurized solar water heater of the present invention includes a heat collecting header 15, a plurality of heat collecting and conducting units arranged in parallel, a pressurized water tank 8, and a temperature difference control unit; A plurality of heat-collecting and heat-conducting units arranged in parallel are installed on a heat-collecting header 15, and a heat-exchanging coil 82 is arranged in the pressurized water tank 8, and one end of the heat-exchanging coil 82 passes through the A interface 801 of the pressurized water tank 8 Connect to the B interface 152 of the heat collecting header 15 through the A conduit 6, and the other end of the heat exchange coil 82 passes through the B interface 802 of the pressurized water tank 8 and then connects to the A interface of the heat collecting hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com