Volume metering method

A volume measurement and volume technology, applied in the field of volume measurement, can solve the problems of inaccurate volume measurement, generation of air bubbles, and incomplete emptying of the volume metering tube of the blood cell analyzer, so as to avoid aggregation, complete emptying, and eliminate adverse effects The bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

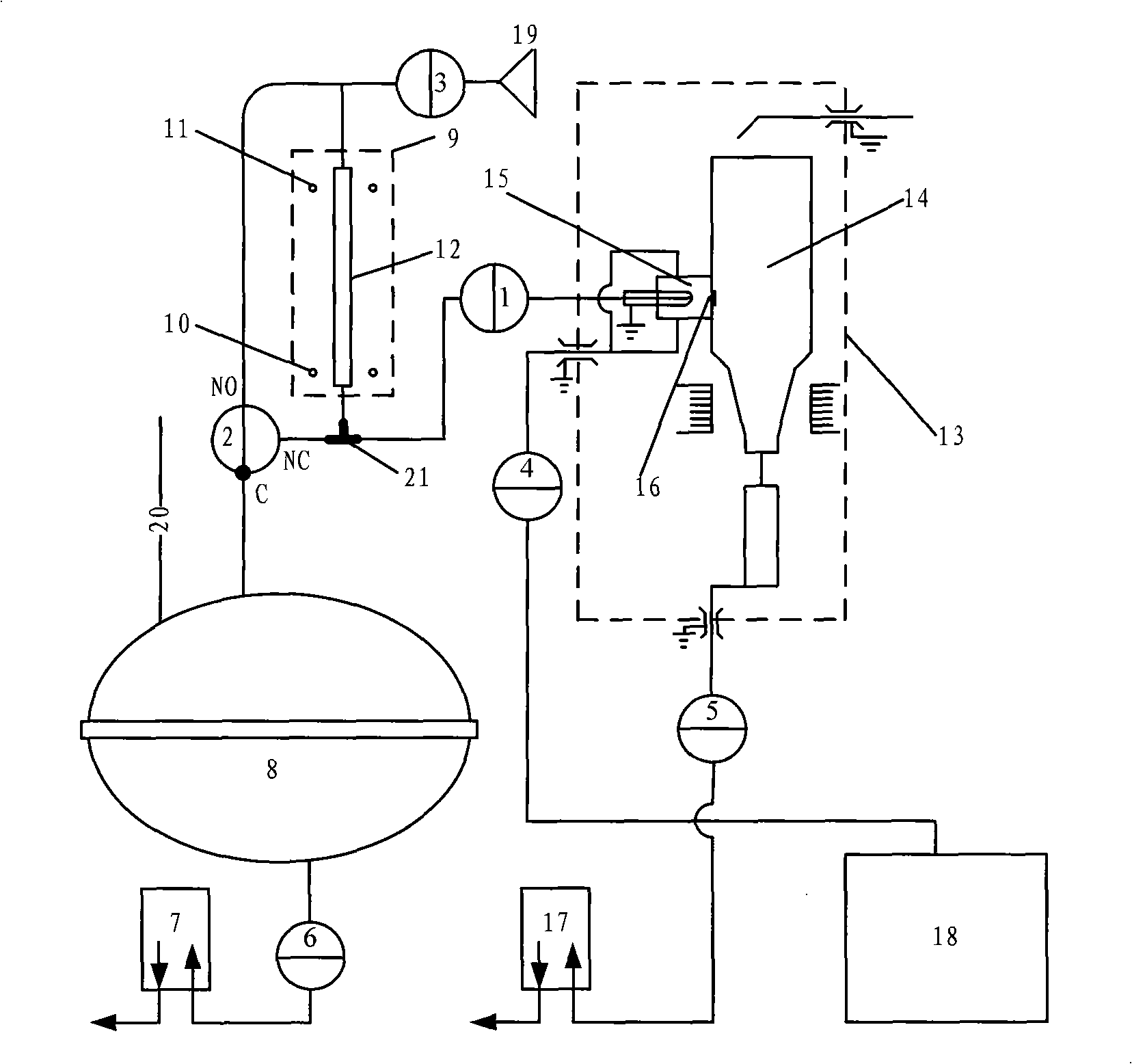

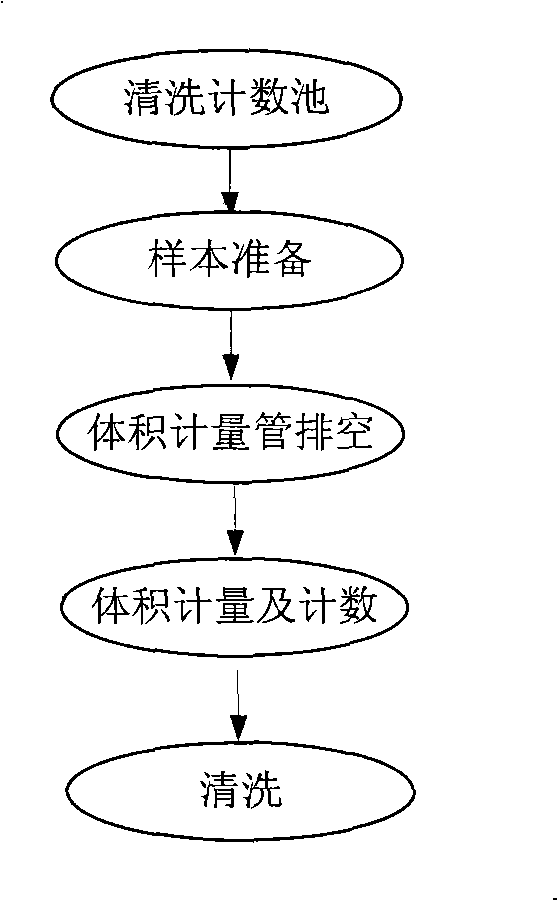

[0041] For the volume metering device of this embodiment, the layout of its liquid circuit can be found in figure 1 shown. The present invention ensures that the volumetric tube is completely emptied through a new auxiliary method for emptying the volumetric tube; at the same time, a new counting start method is used to ensure that even if there is liquid residue at the beginning of counting, the liquid will not jump up, thereby ensuring No air bubbles affect the performance of counting during counting.

[0042] The specific process of emptying the volume metering tube and volume measurement is as follows: Figure 5 , 6 shown, including the following steps:

[0043] Step 1: Establish a negative pressure, open the fifth two-way valve 6, and the first liquid pump 7 to establish a certain negative pressure in the vacuum chamber 8, and the pressure detection sensor 20 has been monitoring the pressure in the vacuum chamber 8;

[0044] Step 2: Empty the volume metering tube, ope...

Embodiment 2

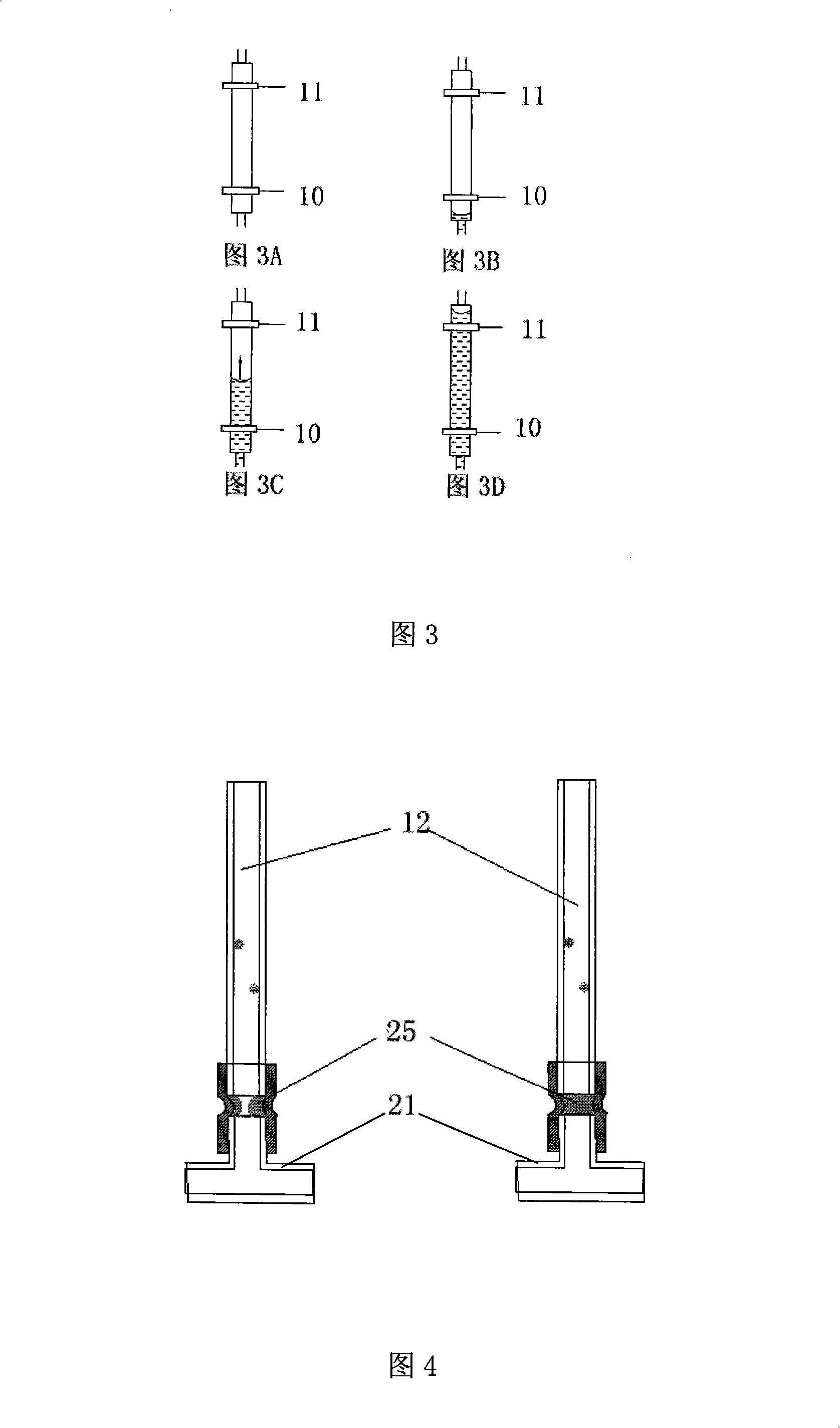

[0052] The liquid path layout of this embodiment is as follows Figure 7 shown, is actually in the original figure 1 Some changes have been made on the basis of , specifically, the sixth two-way valve 22 and the seventh two-way valve 23 are used instead of the first three-way valve 2 in FIG. 4 . That is, the vacuum chamber 8 is connected to the three-way head 21 at the lower end of the volumetric tube 12 through the seventh two-way valve 23 , and the vacuum chamber 8 is also connected to the upper end of the volumetric tube 12 through the sixth two-way valve 22 . Under this pipeline layout, the same effect of the present invention can also be achieved.

[0053] Similarly, the emptying process of the volume metering tube 12 in this embodiment includes the following steps:

[0054] Step 1: Open the fifth two-way valve 6 and the first liquid pump 7 to establish a certain negative pressure on the vacuum chamber 8;

[0055] Step 2, open the seventh two-way valve 23 and the secon...

Embodiment 3

[0059] The liquid path layout of this embodiment is as follows Figure 8 As shown, some changes are actually made on the basis of the original figure 4, specifically, the second three-way valve 24 is used instead of the second two-way valve 3 in Figure 4 . The common end of the second three-way valve 24 is connected to the upper end of the volume metering pipe 12 , the normally open end is connected to the outside atmosphere through the air filter 19 , and the normally closed end is connected to the normally closed end of the first three-way valve 2 . Under this pipeline layout, the same effect of the present invention can also be achieved.

[0060] Similarly, the emptying process of the volume metering tube 12 in this embodiment includes the following steps:

[0061] Step 1: Open the fifth two-way valve 6 and the first liquid pump 7 to establish a certain negative pressure on the vacuum chamber 8;

[0062] Step 2, open the first three-way valve 2 and the second three-way va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com