Electric heating tube heater of carbon product

A technology of carbon products and electric heating tubes, applied in ohmic resistance heating parts, heating elements, heating element shapes, etc., can solve the problems of slow heating and cooling, low thermal efficiency, and easy circuit breakage, etc., to achieve constant temperature and high heating efficiency High, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

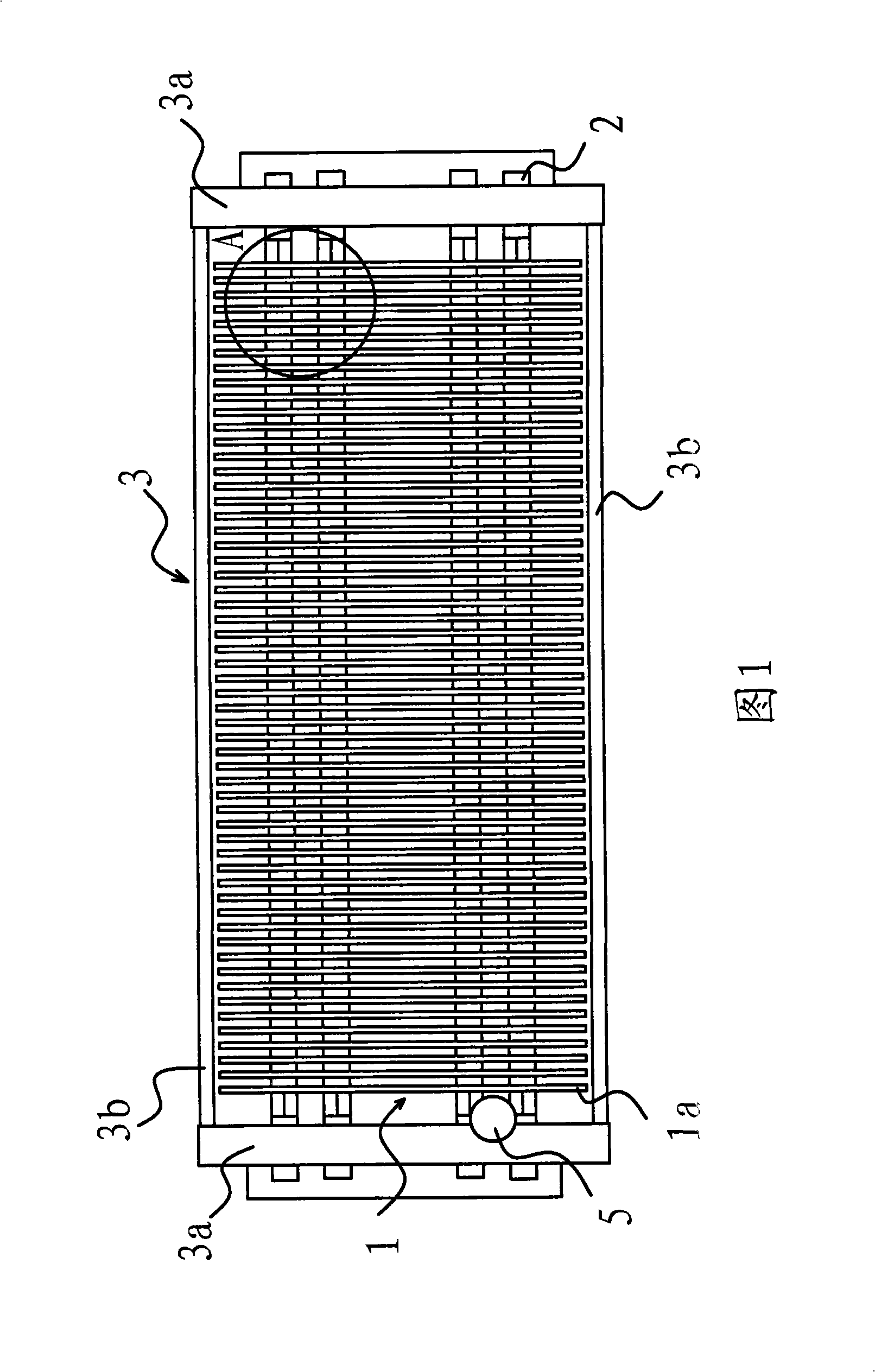

[0030] As shown in FIG. 1 , the carbon product electric heating tube heater includes a body 1 with several vertically arranged cooling fins 1a. The main body 1 is pierced with four electric heating tubes 2 of carbon products arranged in parallel, and the electric heating tubes 2 of carbon products are fixed on the frame 3 .

[0031] Since the carbon product electric heating tube 2 is used as the heating tube, and the carbon product electric heating tube 2 is fixed on the frame 3 . This effectively increases the mechanical strength of the entire device. The heating and cooling process of the invention is fast, the heat generation efficiency is high, and power attenuation will not occur even in long-term use, thus having high safety. The main body 1 is made of any one of copper, aluminum, and alloy materials; the carbon heating element in the carbon electric heating tube 2 is made of any one of carbon sheet, carbon fiber, carbon felt, and carbon braid; The lamp tube 2a of the ...

Embodiment 2

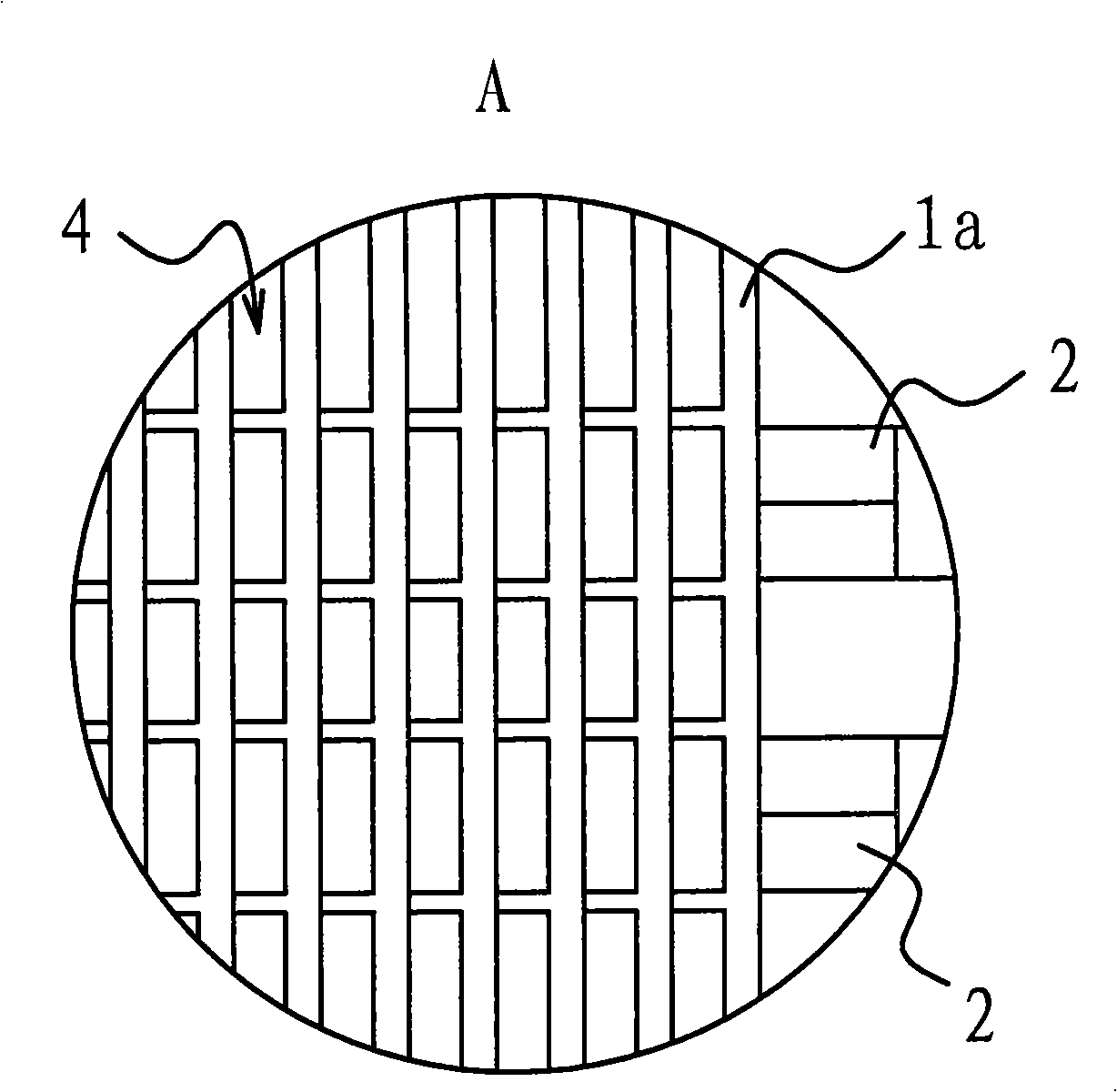

[0037] In the example, as figure 2 As shown, the main body 1 is a split structure, and the main body 1 is composed of several joint sleeves 4 set on the carbon electric heating tube 2, and two adjacent joint sleeves 4 are close to each other. Since there is no gap between the two joint sleeves, no thermal energy loss will be caused. Other structures of this embodiment are substantially the same as those of Embodiment 1, and will not be described in detail herein.

Embodiment 3

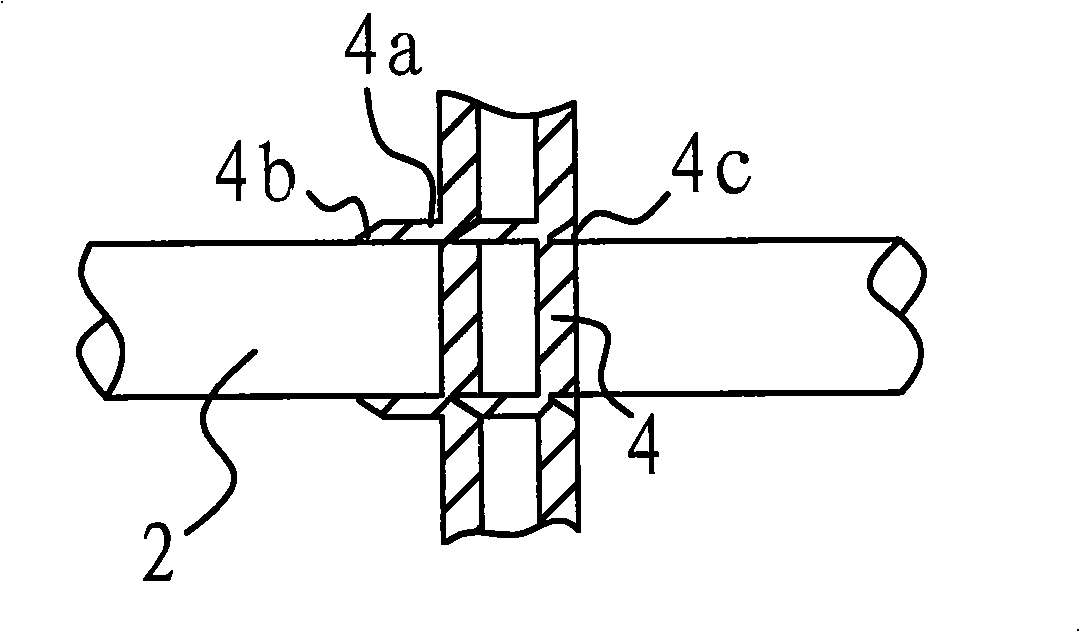

[0039] In this example, if image 3 As shown, the joint sleeve 4 includes a sleeve body 4a, on which at least one heat sink 1a is arranged vertically, the front end of the sleeve body 4a is provided with a wedge-shaped 4b that can be inserted into the rear end of another joint sleeve, the sleeve body The rear end of 4a is provided with a gap 4c for inserting the front end of the sleeve body 4a of another segment sleeve 4 . Other structures of this embodiment are substantially the same as those of Embodiment 2, and will not be described in detail herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com