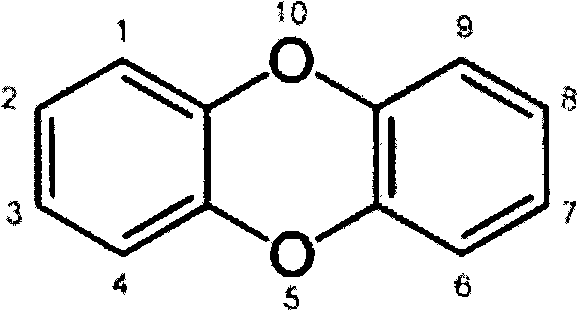

Novel method for processing dioxins in fly ash

A new method, fly ash technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high energy consumption, complex operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Collect fly ash from municipal solid waste incinerators, detect and analyze the content of dioxins in the fly ash, and store it in the same way as cement (anti-moisture absorption and hardening);

[0028] 2. Add 2.0 kg of 1.0% sodium dodecylsulfonate aqueous solution to 400 g of fly ash, and stir for 60 min with a propeller-type agitator whose rotation speed is 100 RPM;

[0029] 3. Separate and extract the sodium dodecylsulfonate aqueous solution containing dioxins from the fly ash suspension by vacuum filtration;

[0030] 4. Add a certain amount of hydrochloric acid to the extract to adjust the pH of the solution to 4.0;

[0031] 5. Heat the extract and maintain the temperature at 99°C±1°C;

[0032] 6. Pass 0.8 (v / v.min) air into the extract for 98 hours continuously;

[0033] 7. Take a sample to detect and analyze the content of dioxins in the liquid, then add lime to neutralize the acidic extract until the pH is 5.5-7.0 and then discharge.

[0034] The degradat...

Embodiment 2

[0042] 1. Collect urban solid waste incineration fly ash, detect and analyze the content of dioxins in the fly ash, and store it in the same way as cement (anti-moisture absorption and hardening);

[0043] 2. Add 50 kg of 0.01% lauryl betaine aqueous solution to 50 kg of fly ash, and stir for 30 min with a cement mortar mixer with a rotation speed of 100 RPM;

[0044] 3. Using a plate and frame filter to separate and extract the dodecyl betaine solution containing dioxins from the fly ash suspension;

[0045] 4. Add a certain amount of sulfuric acid to the extract to adjust the pH of the solution to 6.0;

[0046] 5. Heat the extract and maintain the temperature at 50°C ± 1°C; after reacting under 4 conditions for 48 hours, take a sample to detect and analyze the content of dioxins in the liquid.

[0047] The degradation rate of dioxin-like substances in fly ash is calculated from the above formula (1), and the result shows that the degradation rate of dioxin-like substances i...

Embodiment 3

[0049] 1. Collect fly ash from municipal solid waste incinerators, detect and analyze the content of dioxins in the fly ash, and store it in the same way as cement (anti-moisture absorption and hardening);

[0050] 2. Add 2.0kg of soapy water containing 0.1% soap to 400g of fly ash and stir for 10 minutes;

[0051] 3. Separation and extraction of soapy water containing dioxins from the fly ash suspension by gravity suction filtration;

[0052] 4. Add a certain amount of hydrochloric acid to the extract, adjust the pH value of the solution to 5.5, then heat and maintain it at 30°C ± 1°C, and pass air into the solution for 24 hours;

[0053] 5. Sampling, detection and analysis of the content of dioxin-like substances in the liquid, the degradation rate of dioxin-like substances in fly ash was calculated by formula (1), and the results showed that the destruction and degradation rate of dioxin-like substances in fly ash was 72% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com