Self-suction type inner circulation overweight field gas-liquid reactor

A gas-liquid reactor and internal circulation technology, which is applied in chemical methods, chemical instruments and methods, and chemical/physical processes for reacting liquids and gaseous media. High processing technology requirements and other issues, to achieve the effect of inhibiting the accumulation of bubbles, eliminating the macroscopic vortex, and increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

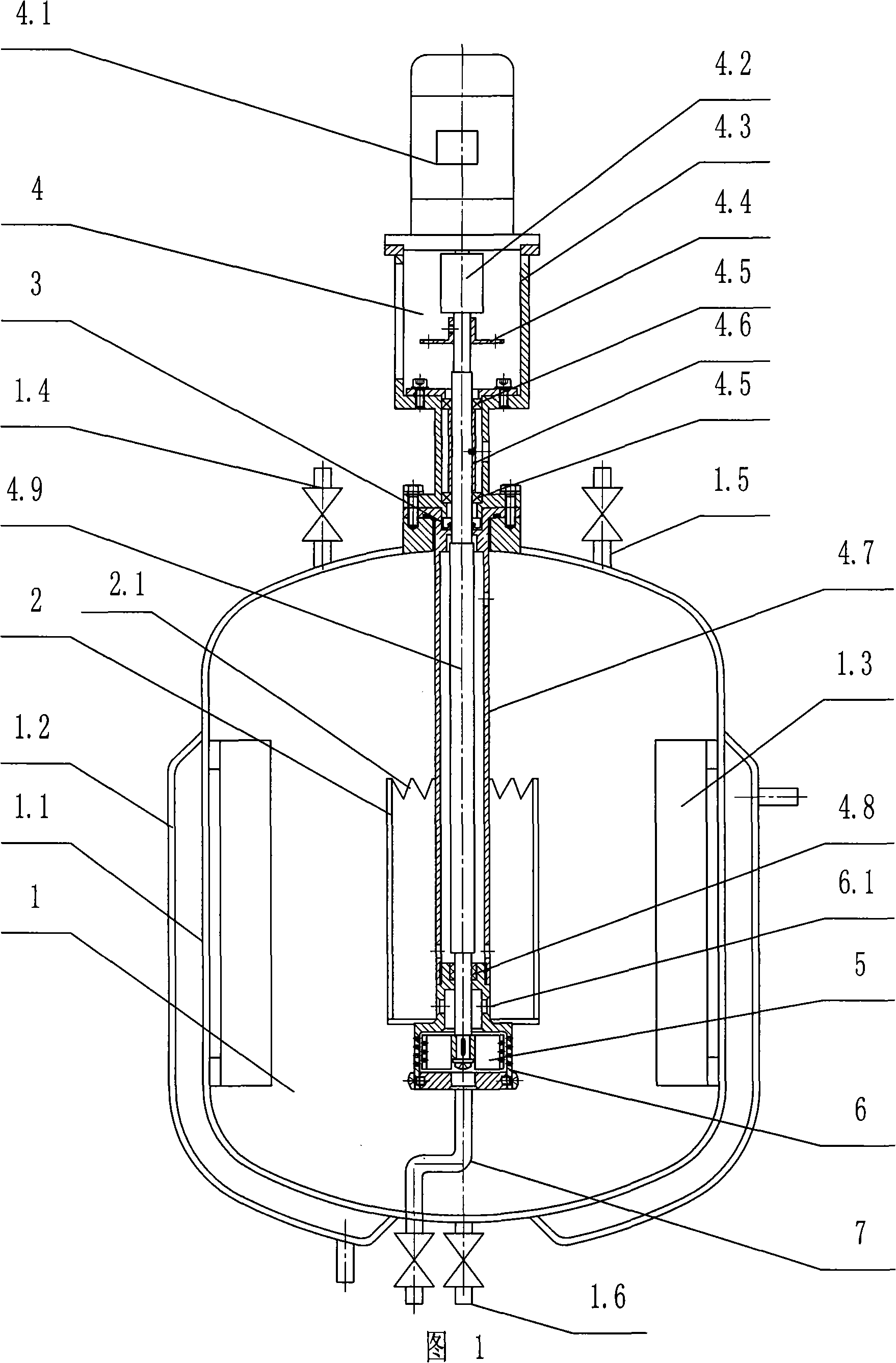

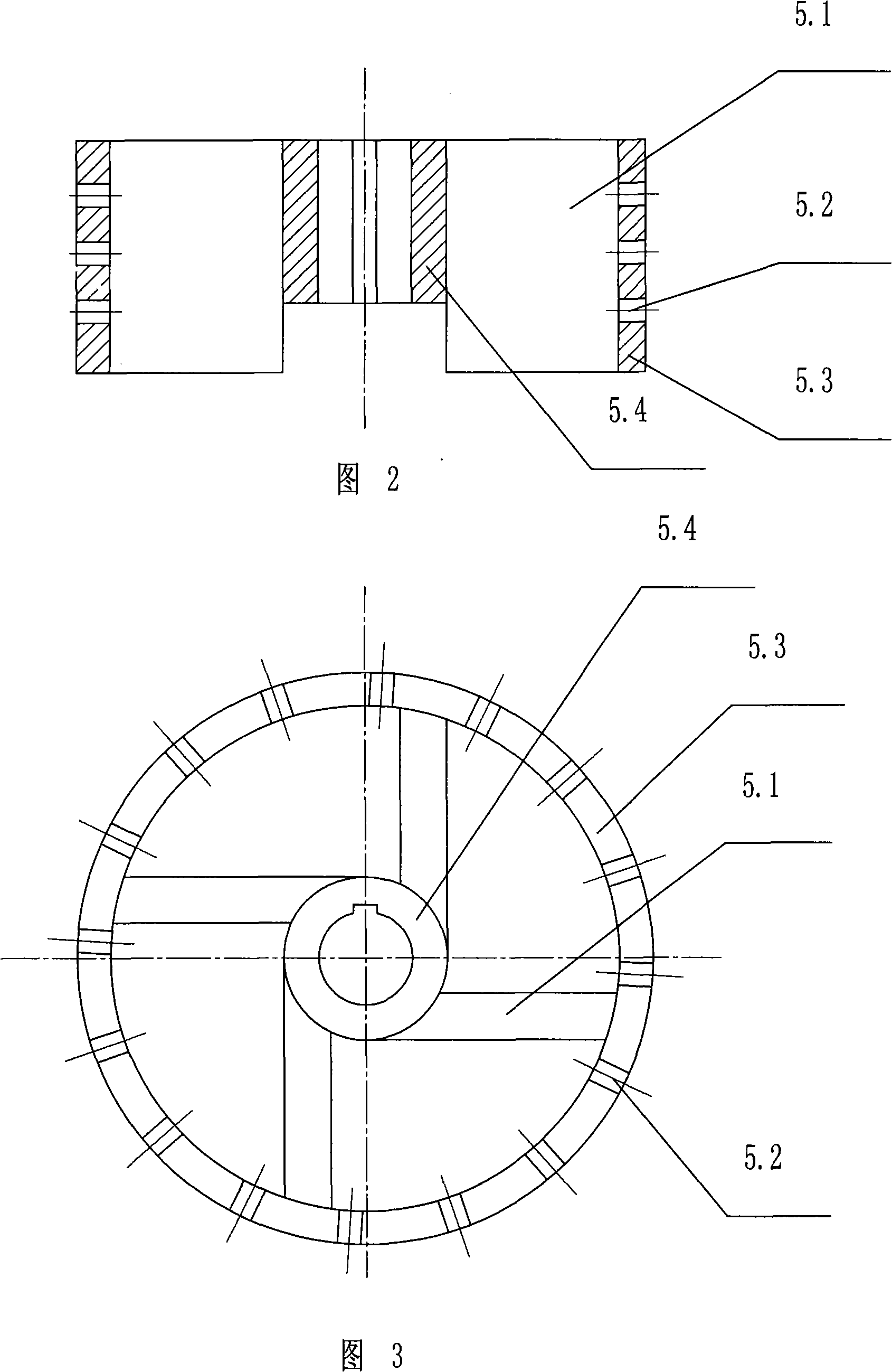

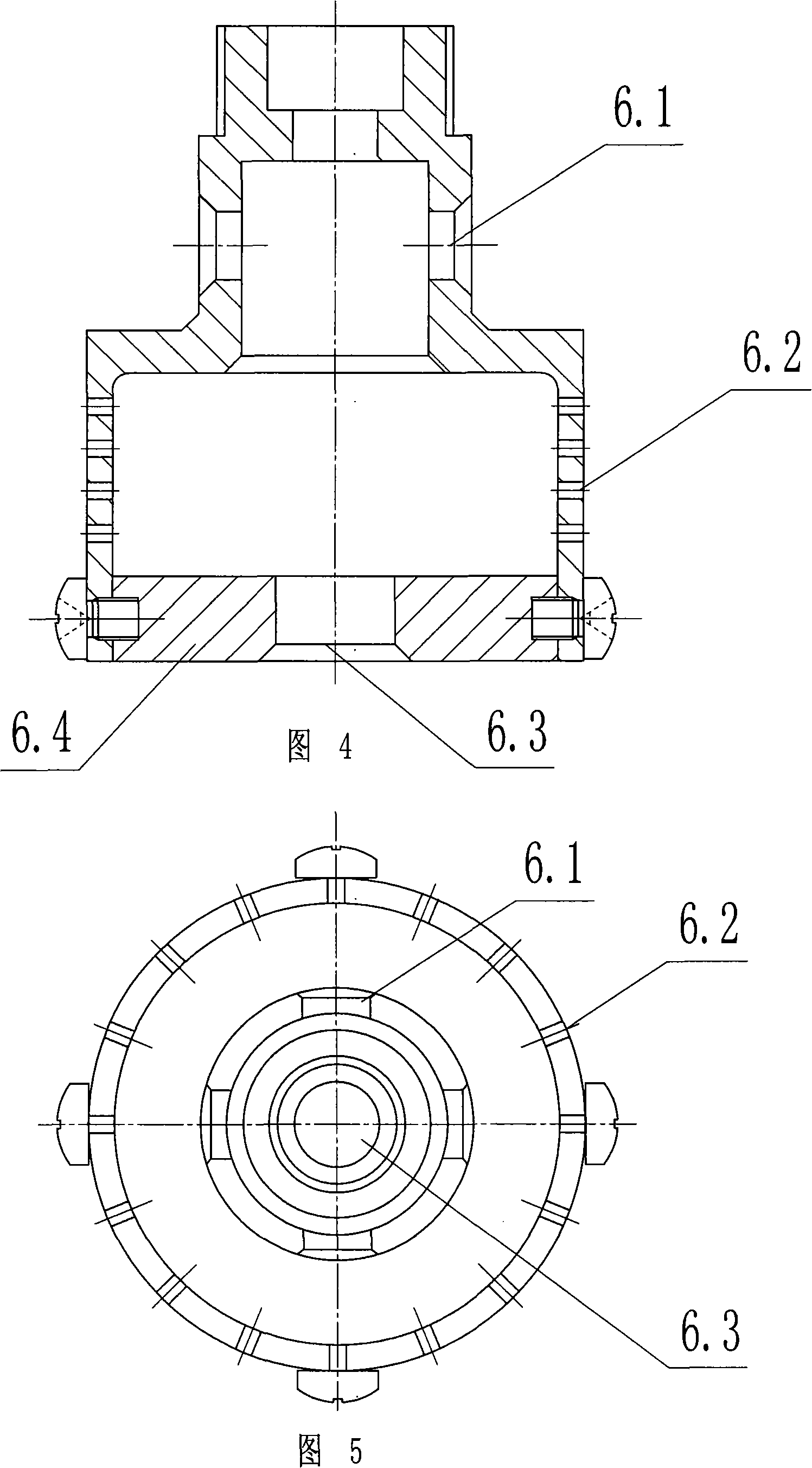

[0017] Figure 1 shows a schematic structural diagram of a self-priming internal circulation super-heavy field gas-liquid reactor, which mainly consists of a reactor vessel main body 1, a power rotor 5, a stator 6, a guide tube 2, a gas inlet pipe 7, a driving mechanism 4 and a sealing mechanism 3, characterized in that: the main body 1 is connected with the driving mechanism 4 and the sealing mechanism 3, the power rotor 5 is connected with the shaft 4.9 of the driving mechanism 4, and installed in the stator 6, and the stator 6 is connected with the connecting pipe 4.7 of the driving mechanism 4, The guide tube 2 is connected with the stator 6 , and the gas inlet pipe 7 is arranged at the lower part of the stator 6 .

[0018] The container body 1 includes an inner cylinder 1.1, a jacket 1.2 located outside the inner cylinder 1.1, and several baffles 1.3 parallel to the axis 4.9 located on the inner wall of the inner cylinder 1.1. The relevant process nozzles mainly include a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com