Ring shaped air flotation machine

A flotation machine, ring-shaped technology, applied in flotation, solid separation, etc., can solve the problems of unstable flotation effect, high enrichment ratio, fast wall wear, etc., and achieve selection and sweeping time and frequency adjustment Flexible, overcome the low recovery rate, and reduce the effect of equipment wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

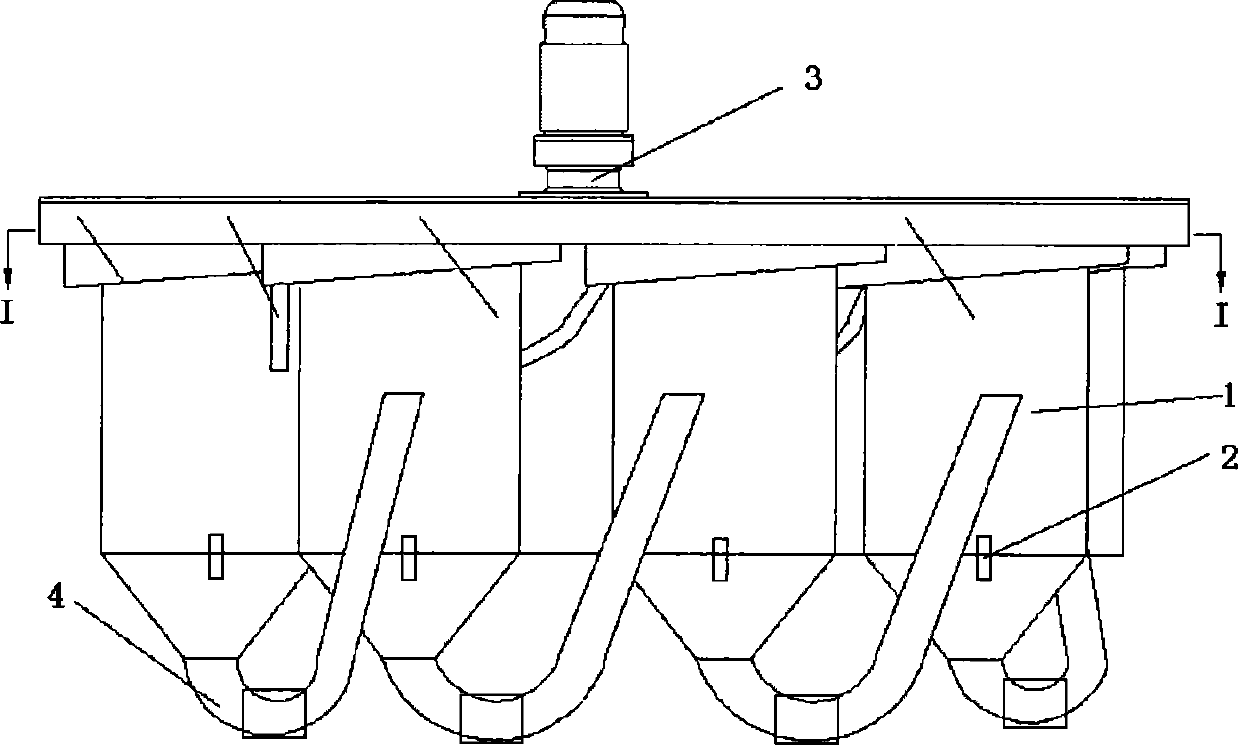

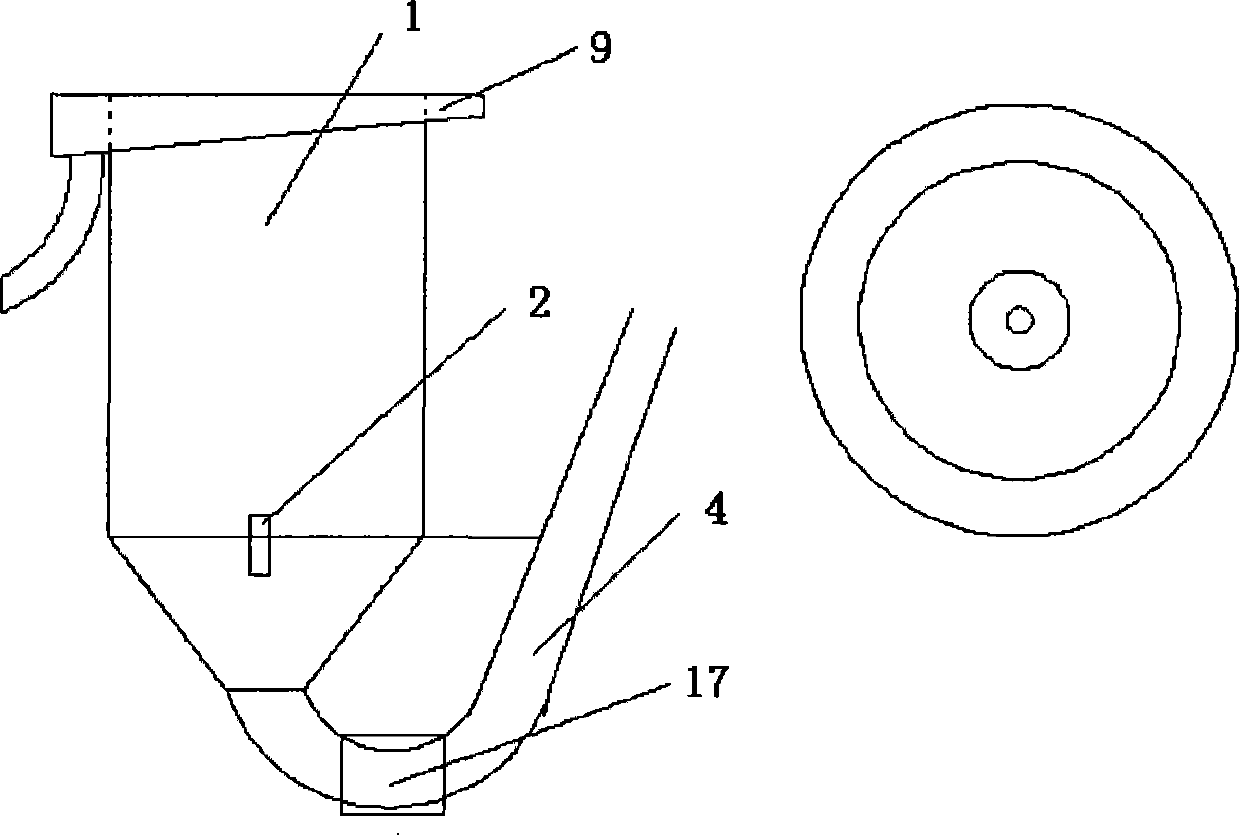

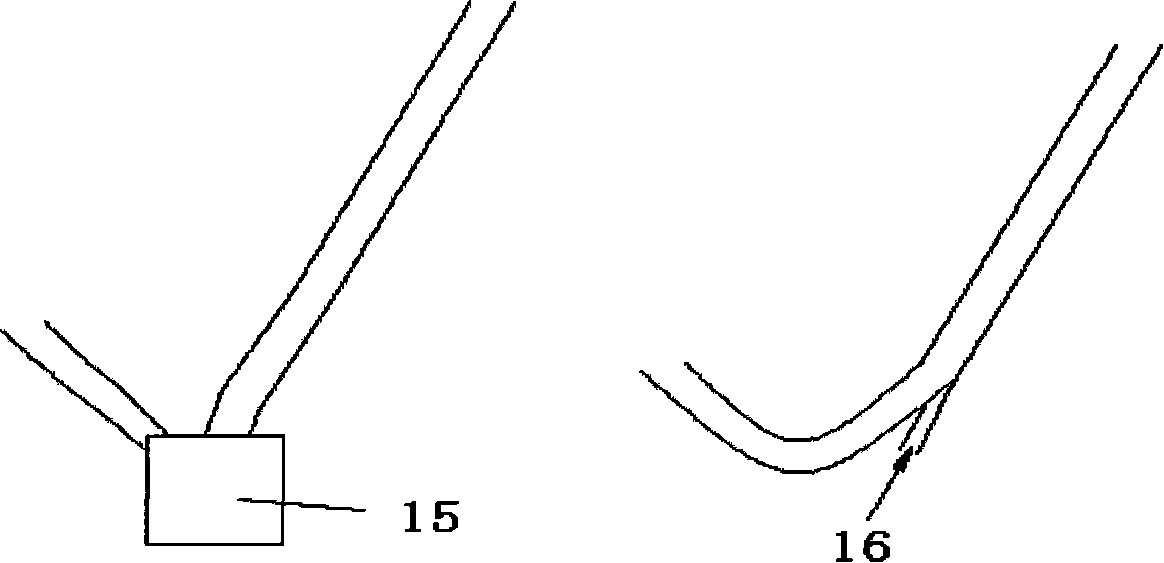

[0038] 1. The composition of the ring inflatable flotation machine: such as figure 1 As shown, it consists of a sorting column 1, a press-in air type bubble generator 2, an annular foam scraper mechanism 3, and a process pulp riser 4; the sorting column 1 consists of a column body 5, a foam concentrate feeding port 6, a central The ore feeding port 7, the tailings port 8, and the concentrate ring groove 9 are composed. The cross-sectional shape of the separation column 1 can be one of circular, rectangular or isosceles trapezoidal, and the ratio of the equivalent diameter of the cross-sectional area to the height is D / L=0.25~0.83; the annular foam scraper mechanism 3 is composed of a motor 10, a reducer 11, a scraper frame 12, a support frame 13, and a scraper 14; n separation columns 1 are combined to form a ring (n=n1 +n2+1, where: n1 is the number of selections required for the ore determined by the mineral processing test, n2 is the number of sweeps required for the ore de...

Embodiment 2

[0046] 1. The structure of the annular air-filled flotation machine is the same as that of Embodiment 1.

[0047] 2. Ore processing: copper sulfide ore with raw ore grade of 1.2%, grinding particle size: -200 mesh, accounting for about 85%.

[0048] 3. The structural parameters of the ring inflatable flotation machine are:

[0049] 1) The section shape of the sorting column is isosceles trapezoid, the upper bottom of the isosceles trapezoid is 1000mm, the lower bottom is 500mm, the height is 1000mm, the equivalent diameter of the sectional area is 489mm, and the height is 1950mm. The ratio of the equivalent diameter of the sectional area of the column to the height is D / L=0.25, the number of separation columns n=n1+n2+1=12, wherein n1=5, n2=6;

[0050] 2) Pressurized air is introduced into the middle of the process slurry riser as the lifting power of the middling ore.

[0051] 4. Obtained technical indicators:

[0052] Copper concentrate contains copper grade ≥ 25%, cop...

Embodiment 3

[0054] 1. The structure of the annular air-filled flotation machine is the same as that of Embodiment 1.

[0055] 2. Ore processing: raw ore grade is 4% zinc sulfide ore, grinding particle size: -200 mesh accounts for about 75%.

[0056] 3. The structural parameters of the ring inflatable flotation machine are:

[0057] 1) The cross-sectional shape of the sorting column is rectangular, the length of the rectangle is 1000mm, the width is 1200mm, the equivalent diameter of the cross-sectional area is 618mm, and the height is 1800mm. n=n1+n2+1=7, wherein n1=3, n2=3;

[0058] 2) A sand pump is installed in the middle of the process slurry riser as the lifting power of the middling mine.

[0059] 4. Obtained technical indicators:

[0060] The grade of zinc contained in zinc concentrate is ≥50%, and the recovery rate of zinc is ≥84%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com