Spring tube type water electrolyser

A spring tube type, electrolysis device technology, applied in the electrolysis process, electrolysis components, sustainable manufacturing/processing and other directions, can solve the problems of easy heating of the electrolytic cell, hinder water electrolysis, increase power consumption, etc., and save power consumption. , the effect of increasing power consumption and saving power consumption

Inactive Publication Date: 2008-10-29

安士英

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current water electrolysis hydrogen and oxygen machine is mainly composed of an electrolytic cell, positive and negative electrodes, connecting pipes, electrolyte, water and gas separator, hydrogen and oxygen outlet, water inlet, water level indicator, circulating water pump, conduit, etc., and has the following defects : 1. The electrolytic tank is prone to heat, which hinders water electrolysis and increases power consumption; 2. The electrolyte water channels in the electrolytic tank and the water-gas separator are connected, and water is a conductive medium. The communication of the water channels means that the circuit is closed, and it is in a energized state , which also increases power consumption, and the gas output is low

In addition, there is a shortage of energy now, and at the same time, environmental pollution is also an urgent problem to be solved

Water electrolysis is used to produce oxyhydrogen gas, although it is environmentally friendly, it consumes a lot of electricity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

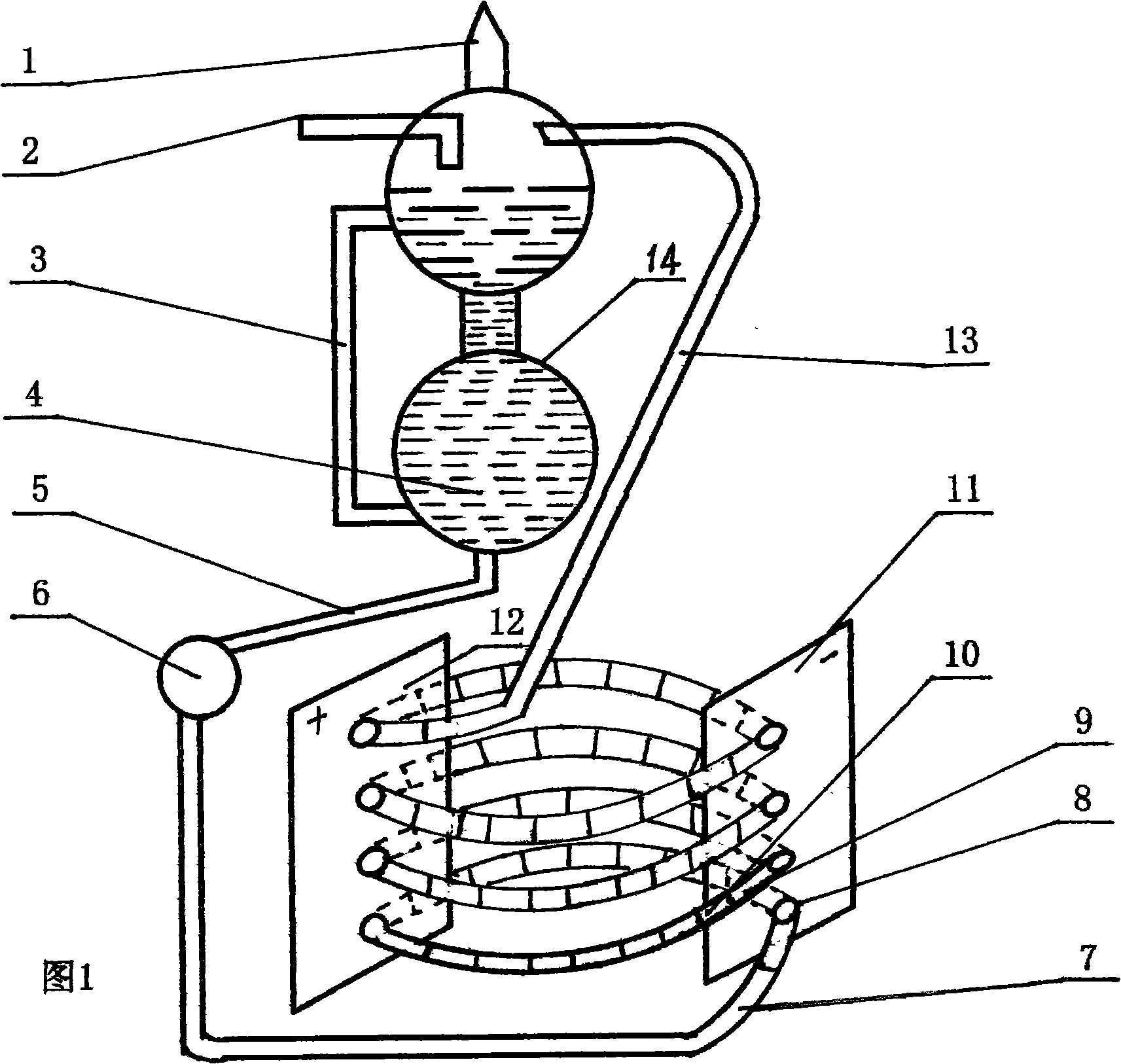

The invention relates to equipment for generating oxyhydrogen through water electrolysis, in particular to a spring tube type water electrolysis device. The electrolysis device is characterized in that on the structural basis of the original oxyhydrogen generator through water electrolysis; the electrolysis device is a spring tube type electrolysis device; the spring tube in the device is spiral and passes through holes on a positive plate and a negative plate; the red copper connecting tube on the spring tube is respectively and firmly connected with the positive plate and the negative plate; the spring tube is formed by a plurality of sections of red copper connecting tubes on which a plurality of sections of plastic tubes are nested in sequence; the spring tube type electrolysis device can adopt a plurality of groups of electrolysis devices which can work in parallel and respectively communicate with a water-gas separator via a connecting tube; a circulating water pump and a connecting tube; the other end respectively communicates with the upper end of the water-gas separator via a conducting tube; the connecting tubes are plastic tubes. The electrolyte makes centripetal movement in the spring tube; under the combined action of centripetal force, centrifugal force and electric power, water is easily decomposed and oxyhydrogen is generated. Therefore, the electrolysis device has the advantages that the electric quantity is saved, the unit volume is small, the heat emission is quick, and the electrolysis device is high voltage resistant, environment friendly and energy saving.

Description

Spring tube water electrolysis device technical field The invention relates to equipment for producing hydrogen and oxygen by electrolysis of water, in particular to a spring tube type water electrolysis device. Background technique The current water electrolysis hydrogen and oxygen machine is mainly composed of an electrolytic cell, positive and negative electrodes, connecting pipes, electrolyte, water and gas separator, hydrogen and oxygen outlet, water inlet, water level indicator, circulating water pump, conduit, etc., and has the following defects : 1. The electrolytic tank is prone to heat, which hinders water electrolysis and increases power consumption; 2. The electrolyte water channels in the electrolytic tank and the water-gas separator are connected, and water is a conductive medium. The communication of the water channels means that the circuit is closed, and it is in a energized state , which also increases power consumption, and the gas output is low. In add...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25B1/04

CPCY02E60/366Y02E60/36Y02P20/10

Inventor 安士英

Owner 安士英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com