Tunnel shield propulsion and inside double-layer road synchronous construction method

A tunnel shielding and simultaneous construction technology, which is applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of limited segment manufacturing and assembly flexibility, great impact on tunnel construction quality, poor structural integrity and earthquake resistance, etc. Problems, to achieve the effect of being beneficial to axis control, beneficial to control, enhancing integrity and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

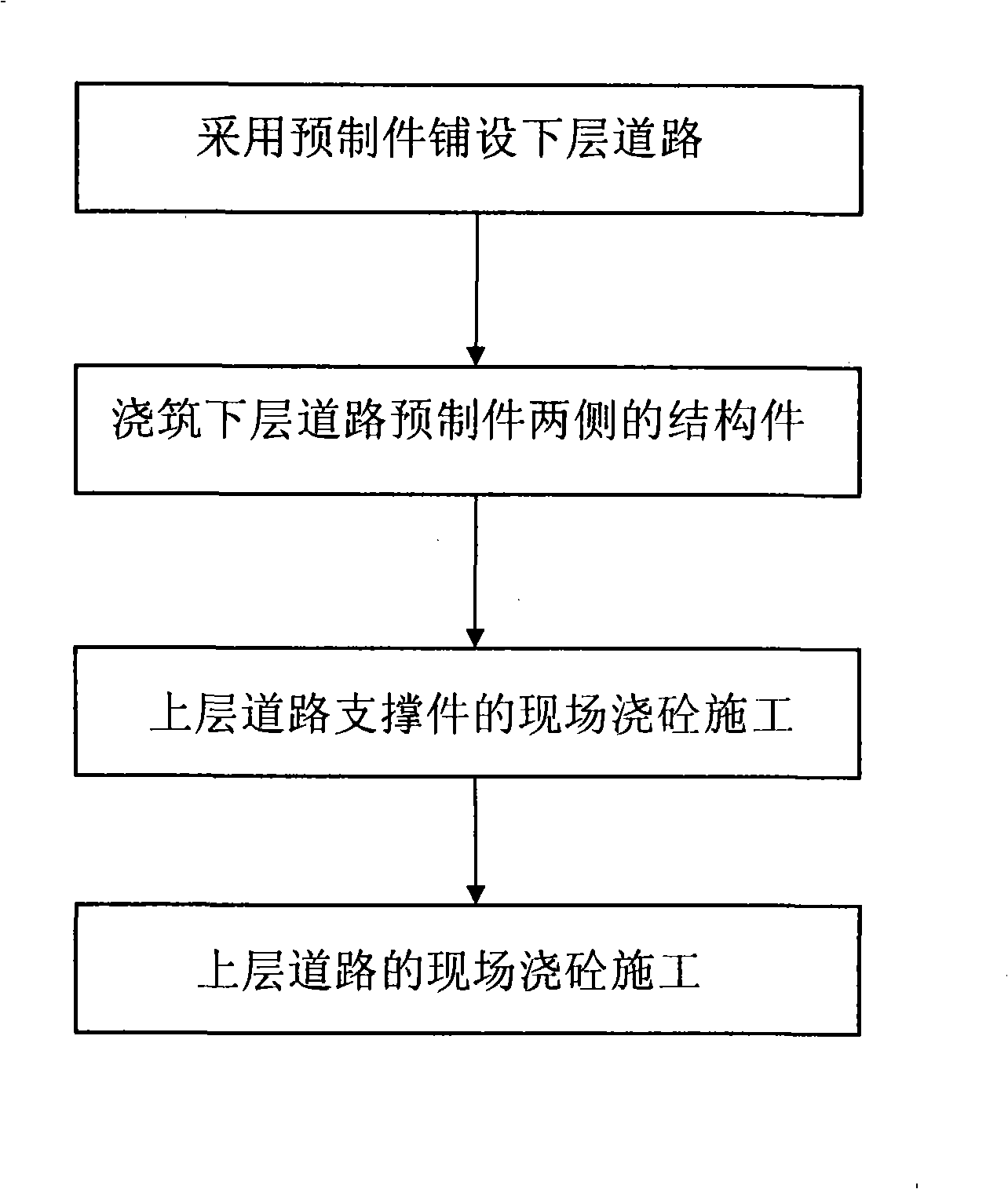

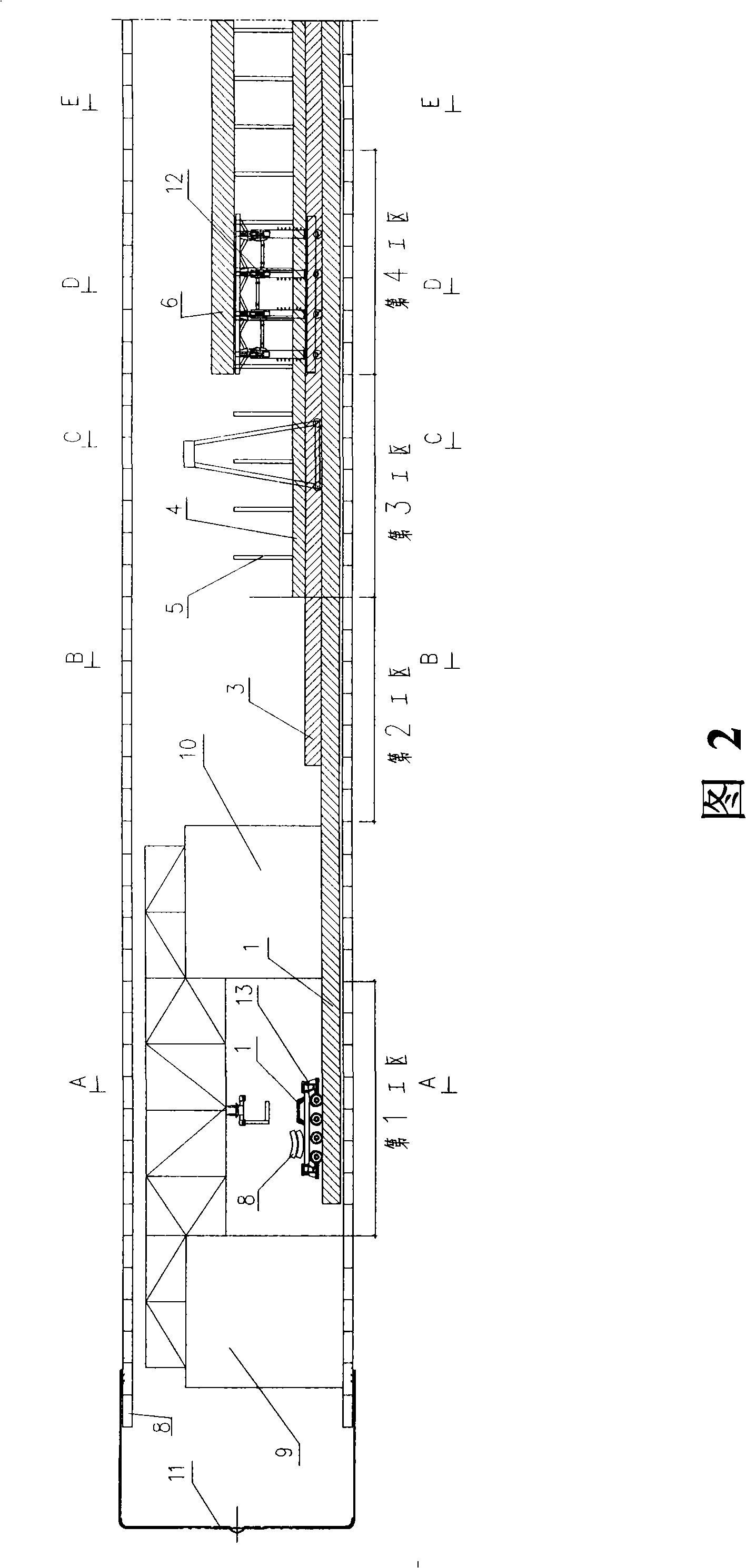

[0054]Please refer to Fig. 2, at the rear of the shield tunneling machine 11 that is advancing, there are four working areas, the 1st, the 2nd, the 3rd and the 4th, in the longitudinal order, which are arranged in sequence and carried out simultaneously in each working area. The following construction operations:

[0055] (1) Prefabricated parts are used to lay the lower road

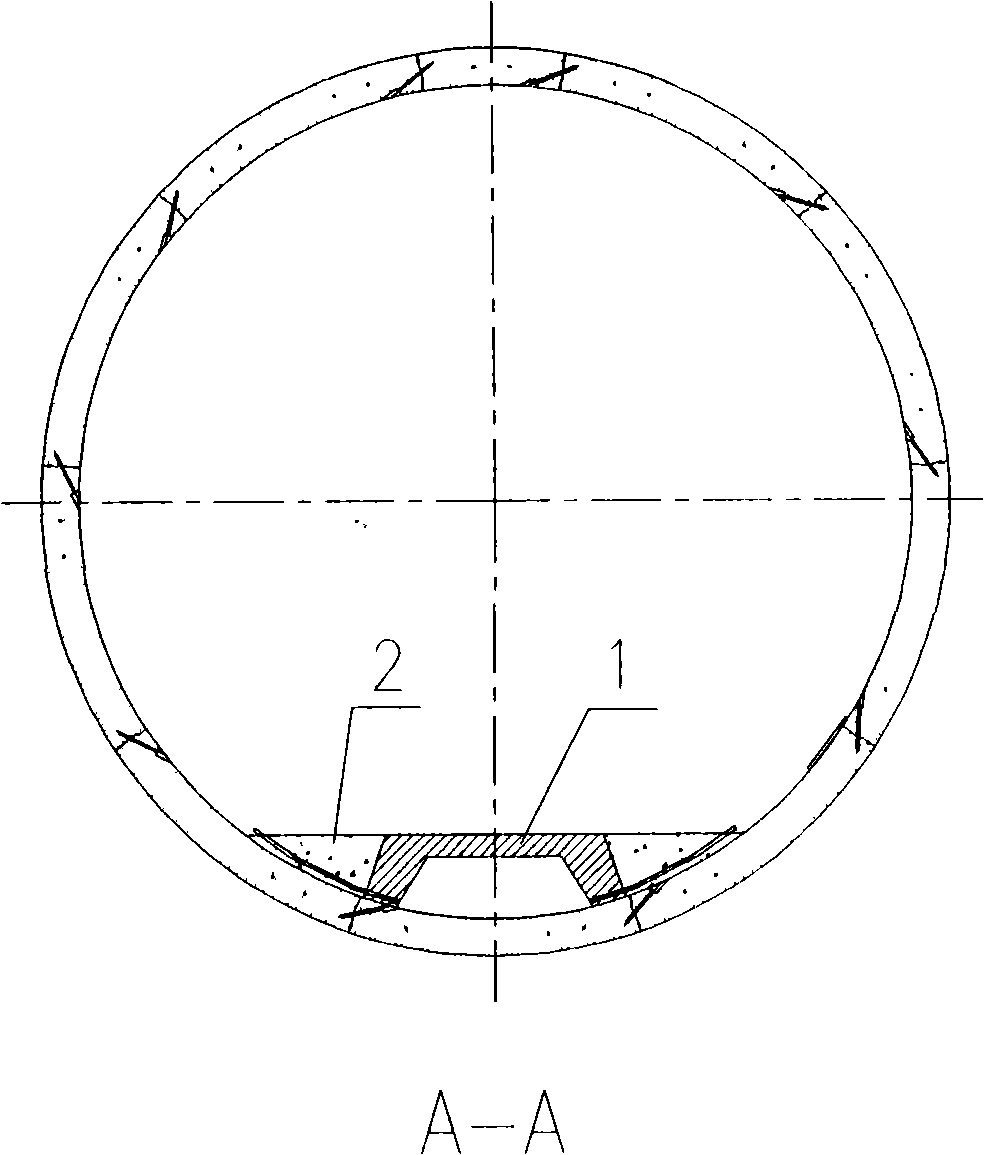

[0056] In the first working area immediately after the shield machine 11, the shield machine 11 carries out excavation construction at the forefront, and immediately behind it immediately assembles the tunnel into a ring segment 8; every time the shield machine 11 assembles a ring segment 8 , the lane slab prefabricated part 1 for paving the lower road is installed immediately and at the same time, that is, the laying of the lane slab prefabricated part 1 and the assembling of the tunnel lining into the ring pipe piece 8 are carried out synchronously. Please refer to image 3 , behind the operation se...

Embodiment 2

[0065] The tunnel project described in Embodiment 2 has a total length of about 7.5km. The inner diameter of the circular section of the tunnel is 13.7m, the outer diameter is 15m, the segment width is 2m, and the thickness is 0.65m. The lower floor is for rail transit. see Figure 8 The schematic diagram of the internal structure of the tunnel in this embodiment, the structure of this tunnel is different from the above-mentioned embodiment 1 in that the lower road adopts the prefabricated part 01 with a square cross section, and the supporting part supporting the upper road 04 is the corbel 03. The construction of the second embodiment also adopts the method of continuous excavation of shield tunneling, subsequent installation and laying of the prefabricated part 01 of the lower road, and on-site pouring of the upper road 04 at the same time. Please refer to Figure 9, behind the advancing shield machine 07, there are four work areas A1, A2, A3 and A4 in the longitudinal orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com