Digital microcurrent-controlled device and control method based on electrowetting effect on dielectric

A digital microfluidic and electrowetting technology, applied in chemical method analysis, instruments, scientific instruments, etc., can solve the problems of high droplet driving voltage, high production cost, unfavorable integration of chips and IC circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

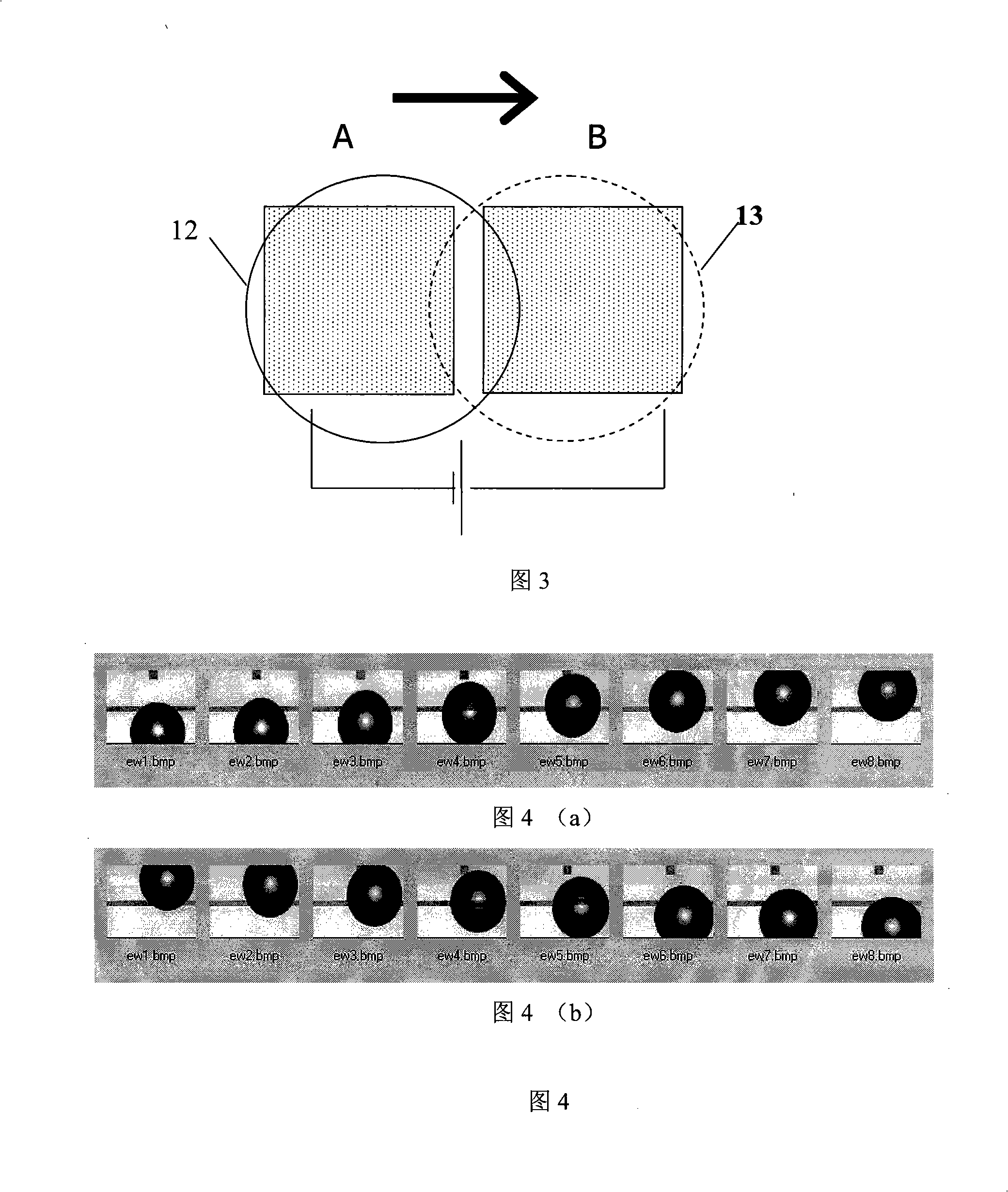

[0029] The invention only needs a simple four-step process to realize the digital microfluidic control function of the droplet, greatly reducing the steps and complexity of the process. The reduction of the operating voltage is also beneficial to the compatibility with the integrated circuit technology, and helps to realize the system integration with the micro-detection.

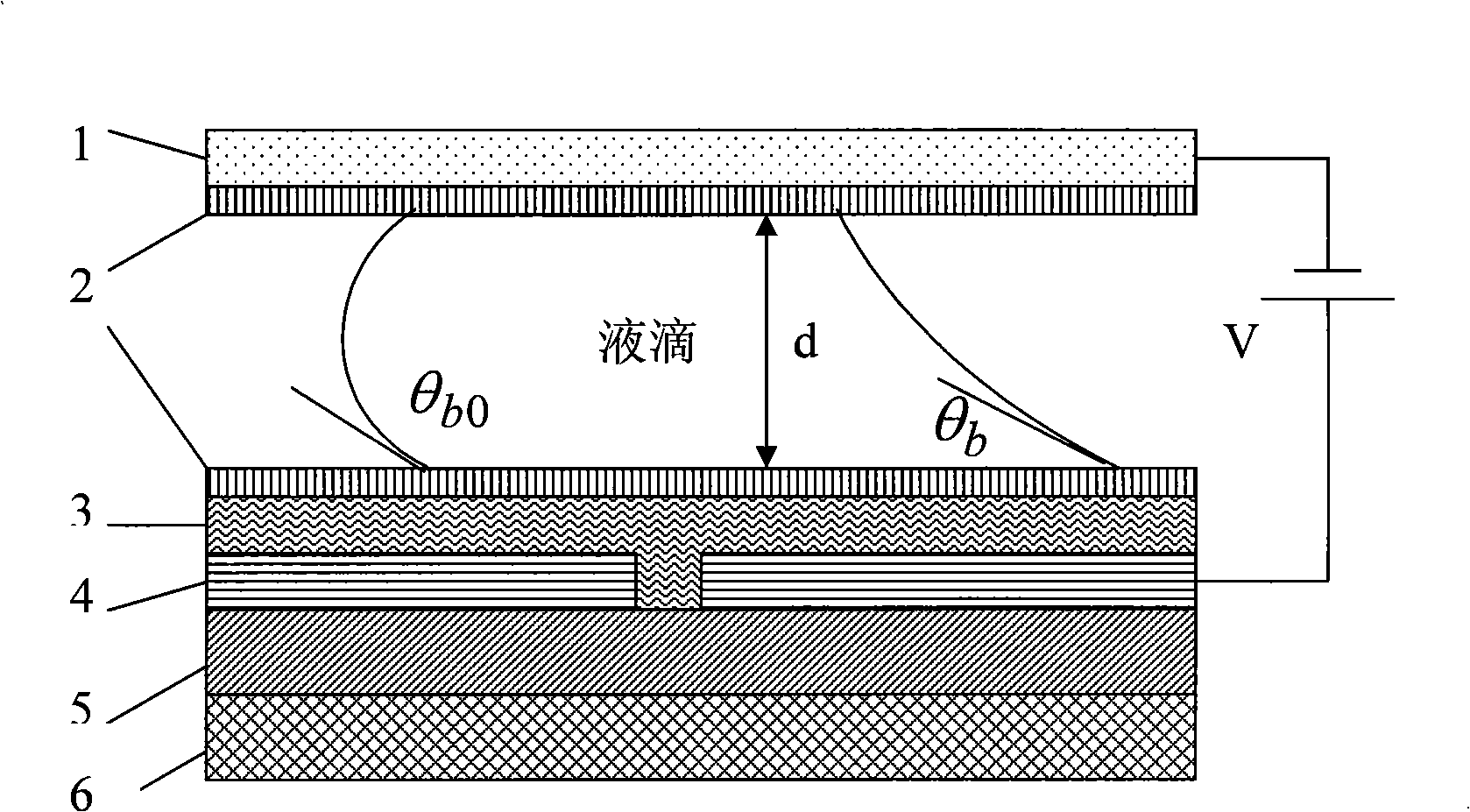

[0030] The specific technological process of the microfluidic device of the present invention is as follows: first, a silicon dioxide layer with a thickness of 700-1000nm is generated by thermal oxidation on the silicon substrate as an insulating layer; secondly, a metal Al layer is evaporated and deposited on the insulating layer, with a thickness of 150-300nm, wet etching to form an electrode pattern; then spin-coat a layer of high dielectric constant organic film (such as P(VDF-TrFE) at a speed of 800-1000 rpm, bake to remove the organic solvent, and form a stable Dielectric layer, the dielectric constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com