Citrus peel pomace anaerobic fermentation processing method

A technology of citrus peel residue and anaerobic fermentation, which is applied in the treatment, application, organic fertilizer and other directions of bio-organic parts, can solve the difficulty in conversion and utilization of organic fertilizers, and it is difficult to deal with citrus peel residues and citrus peel residues in a timely and effective manner on a large scale. Problems such as large amount of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

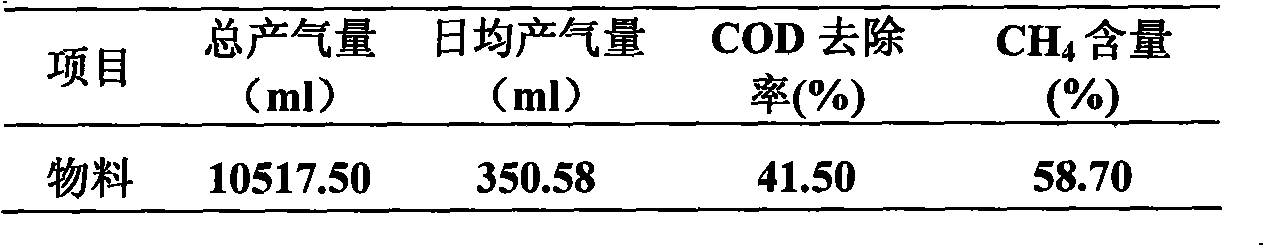

[0014] Fully mix 0.933kg of citrus peel residue (moisture content 82.30%, the same below) with 0.400kg pig manure (water content 81.07%, the same below), without stacking, add urea 8.88g to adjust the fermentation material C / N to 25: 1. Then add 0.853kg of inoculum (the solid content is about 5.65%, the same below), and add 1.814L of tap water, mix well, and anaerobically ferment for 30d at an average temperature of 20°C. During the fermentation process, adjust and maintain the pH of the fermentation broth between 6.5-7.5 with NaOH solution and HCl solution. The results are shown in Table 1.

[0015] Table 1

[0016]

Embodiment 2

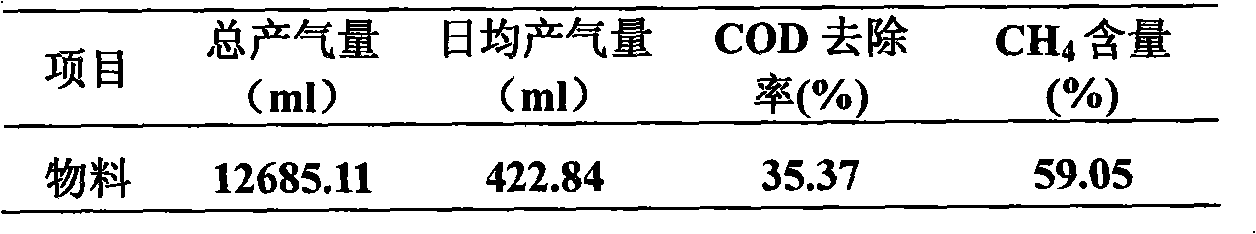

[0018] Fully mix 0.800kg of citrus peel residue with 0.533kg of pig manure without stacking and retting, add 8.88g of urea to adjust the C / N of the fermentation material to 25:1, then add 0.853kg of inoculum, and add 1.814L of tap water, mix thoroughly, Anaerobic fermentation was carried out for 30 days at an average temperature of 20°C. During the fermentation process, adjust and maintain the pH of the fermentation broth between 6.5-7.5 with NaOH solution and HCl solution. The results are shown in Table 2.

[0019] Table 2

[0020]

Embodiment 3

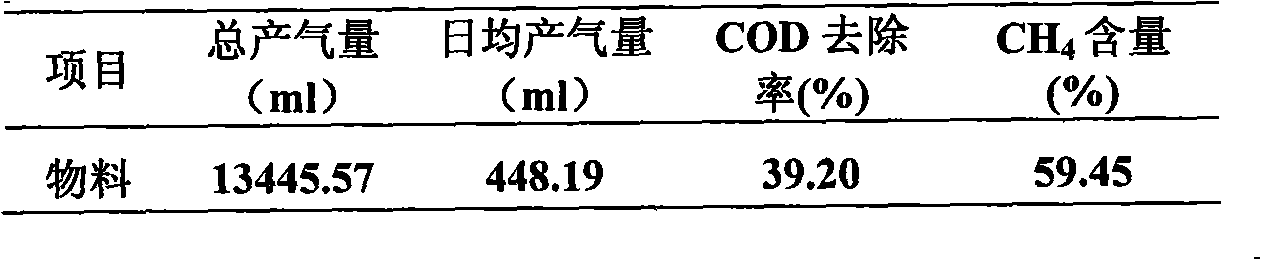

[0022] Fully mix 0.667kg of citrus peel and 0.667kg of pig manure without stacking and retting, add 8.88g of urea to adjust the C / N of the fermentation material to 25:1, then add 0.853kg of inoculum, and add 1.814L of tap water, mix thoroughly, Anaerobic fermentation was carried out for 30 days at an average temperature of 20°C. During the fermentation process, adjust and maintain the pH of the fermentation broth between 6.5-7.5 with NaOH solution and HCl solution. The results are shown in Table 3.

[0023] table 3

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com