Durian flavor sugar-free chewing gum and method for producing the same

A technology for chewing gum and durian, which is applied in the directions of chewing gum, food preparation, food science, etc., can solve the problems of short action time, dental caries, low interest, etc., and achieve the effect of promoting appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The ingredients and weight ratio of each raw material are generally: gum base: 20; xylitol: 15; sorbitol: 40; mannitol: 5; maltitol pulp: 15; durian essence: 3; : 2.0.

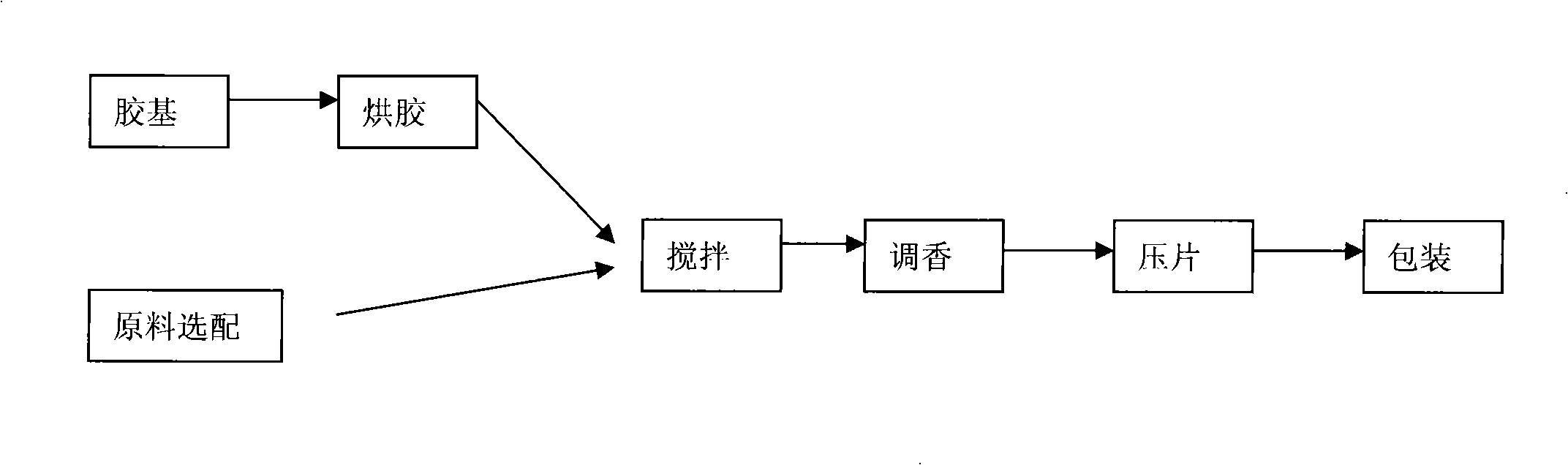

[0018] The manufacture method of described durian flavor sugar-free chewing gum is implemented in the following steps:

[0019] 1. Raw material prefabrication:

[0020] Glue drying: 55°C, 8 hours;

[0021] 2. Feeding, stirring, and flavoring: Mix gum base, xylitol, sorbitol, mannitol, maltitol syrup, glycerin, and lecithin together, stir evenly, and then add durian essence to flavor;

[0022] 3. Tablet molding: Extrude the stirred chewing gum base material in a constant temperature extruder at 50°C; press it into a certain specification of sugar tablets, put it in a ripening room with a constant temperature of 18°C and a constant humidity of 50°C for aging 10 hours;

[0023] 4. Packaging and inspection.

Embodiment 2

[0025] The ingredients and weight ratio of each raw material are generally: gum base: 25; xylitol: 13; sorbitol: 45; mannitol: 7; maltitol pulp: 11; durian essence: 2; : 1.0.

[0026] The manufacture method of described durian flavor sugar-free chewing gum is implemented in the following steps:

[0027] 1. Raw material prefabrication:

[0028] Glue drying: 60°C, 7 hours;

[0029] 2. Feeding, stirring, and flavoring: Mix gum base, xylitol, sorbitol, mannitol, maltitol syrup, glycerin, and lecithin together, stir evenly, and then add durian essence to flavor;

[0030] 3. Tablet molding: extrude the stirred chewing gum base material in a constant temperature extruder at 55°C; press it into sugar tablets of a certain specification by a tablet press, and put them in a ripening room with a constant temperature of 20°C and a constant humidity of 55°C for aging 13 hours;

[0031] 4. Packaging and inspection.

[0032] Example 2:

[0033] The ingredients and weight ratio of each r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com