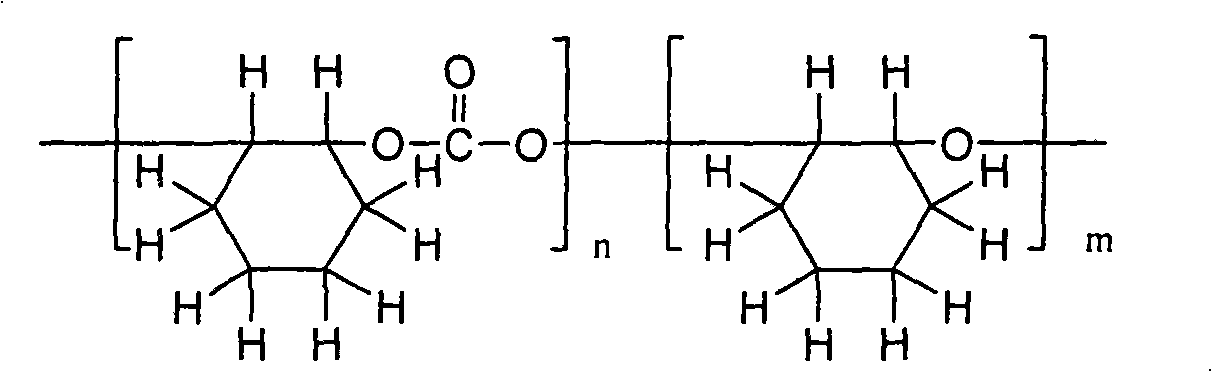

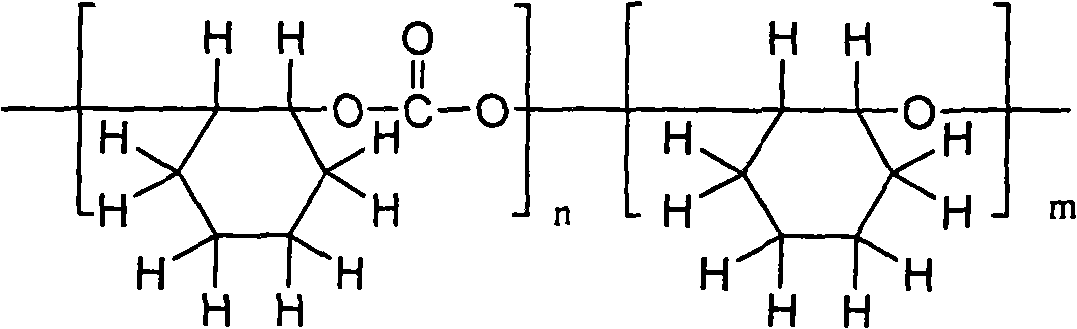

Carbon dioxide-cyclohexene oxide copolymer brittlement modified method

A cyclohexene copolymer and cyclohexene oxide technology, applied in the polymer field, can solve problems such as brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take PCHC (weight average molecular weight 230,000, molecular weight distribution 3.5, n:(n+m)=0.9) 80g (parts by weight, the same below), ABS 10g, acrylonitrile-styrene-acrylic acid terpolymer AS5M 10g. Mix well and dry in vacuum at 80°C for 10 hours. The blend of PCHC and ABS was obtained by banburying at 200°C at a speed of 30r / min in a Haake internal mixer.

[0017] The above blends were made into film tensile samples, and the tensile properties were tested. The Young's modulus is 1.8GPa, the tensile strength is 41.4MPa, the elongation at break is 3.3%, and the glass transition temperature is 119°C.

Embodiment 2

[0019] Take PCHC (weight average molecular weight 230,000, molecular weight distribution 2.5, n: (n+m)=0.95) PCHC 80g, ABS10g, acrylonitrile-styrene-acrylic acid terpolymer AS5M 10g, dissolve in 50ml chloroform under nitrogen protection , most of the chloroform was distilled off under reduced pressure, mixed evenly, and dried under vacuum at 80°C for 10 hours.

[0020] The above blends were made into film tensile samples, and the tensile properties were tested. The Young's modulus is 1.4GPa, the tensile strength is 42MPa, the elongation at break is 8.7%, and the glass transition temperature is 111.3°C.

Embodiment 3

[0022] Take PCHC (weight average molecular weight 190,000, molecular weight distribution 2.5, n:(n+m)=0.86) 70g, ABS 20g, acrylonitrile-styrene-acrylic acid terpolymer AS5M 10g. Mix well and dry in vacuum at 80°C for 10 hours. In a twin-screw extruder, a blend of PCHC and ABS was obtained by banburying at 200° C. at a speed of 30 r / min.

[0023] The above blends were made into film tensile samples, and the tensile properties were tested. The Young's modulus is 1.3GPa, the tensile strength is 33.3MPa, the elongation at break is 4.0%, and the glass transition temperature is 121°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com