Waterless nano-znic antimonite sol and preparation thereof

A technology of nano-zinc antimonate and zinc antimonate, applied in mixing methods, chemical instruments and methods, dissolution, etc., can solve the problems of nano-material function disappearance, inconvenient use, and short storage period of nano-sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Antimony oxide (Sb 2 o 3 ) 25 grams, 100 grams of water, after stirring evenly, add 11.81 grams of basic zinc carbonate while stirring, stir at room temperature for 5 hours, then filter, and dry the filter cake in an oven at 80°C for 6 hours; furnace at 570°C for 10 hours to obtain gray-yellow powder.

[0036] The powder is detected by X-ray diffraction, and the result is: the diffraction peak and diffraction angle are the same as the international standard ZnSb 2 o 6 spectrum Figure 1 It is proved that the grayish-yellow substance is zinc antimonate.

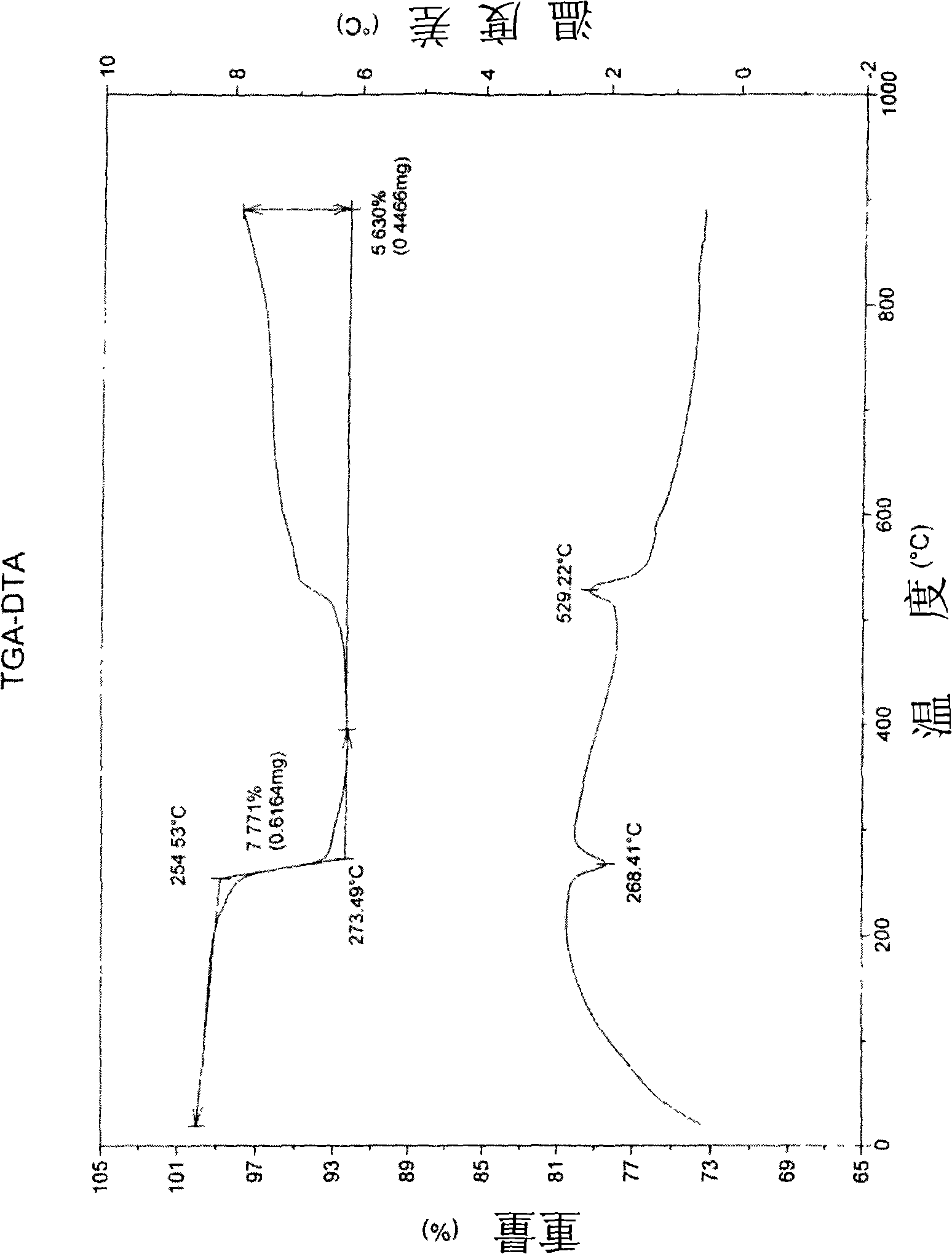

[0037] Anhydrous zinc antimonate solid According to the results of differential thermal analysis (DTA-TG), it is confirmed that the above-mentioned anhydrous zinc antimonate is generated by weight loss method from room temperature to 900°C (see attached figure 1 ).

[0038] The synchronous thermal analyzer STA409PC is used, and the operating conditions are: the temperature rises to 900°C at a rate of 10°C / min. f...

Embodiment 2

[0042] Antimony oxide (Sb 2 o 3 ) 25 grams, 100 grams of water, after stirring evenly, add 11.6 grams of basic zinc carbonate while stirring, stir at room temperature for 5 hours, then filter, and the filter cake is dried in an oven at 70°C for 6 hours; Furnace, sintered at 535°C for 40 hours to obtain grayish yellow powder.

[0043] The powder is detected by X-ray diffraction, and the result is: the diffraction peak and diffraction angle are the same as the international standard ZnSb 2 o 6 spectrum Figure 1 It is proved that the grayish-yellow substance is zinc antimonate.

[0044] Add 33.20 grams of the powder to 40 grams of water and put it into a ball mill jar, grind the balls for 10 hours and rinse with water to obtain 230 grams of zinc antimonate hydrosol. Add 0.78 grams of vinyltrimethoxysilane to the aqueous sol, stir at room temperature for 5 hours, then add 0.39 grams of isopropylamine, 2.1 grams of citric acid, and continue stirring for 2 hours to obtain a com...

Embodiment 3

[0047] Antimony oxide (Sb 2 o 3) 25 grams, 100 grams of water, after stirring evenly, add 12 grams of basic zinc carbonate while stirring, stir at room temperature for 5 hours, then filter, and dry the filter cake in an oven at 80°C for 6 hours; furnace at 550°C for 20 hours to obtain grayish yellow powder.

[0048] The powder is detected by X-ray diffraction, and the result is: the diffraction peak and diffraction angle are the same as the international standard ZnSb 2 o 6 spectrum Figure 1 It is proved that the grayish-yellow substance is zinc antimonate.

[0049] Add 33.66 grams of the powder to 40 grams of water and put it into a ball mill jar, grind the balls for 10 hours and rinse with water to obtain 230 grams of zinc antimonate hydrosol. Add 3.6 grams of vinyltrimethoxysilane to the hydrosol, stir at room temperature for 5 hours, then add 0.69 grams of isobutylamine and 1.9 grams of malic acid, and continue stirring for 2 hours to obtain a solution coated with vin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com