Silicon oil fan clutch

A clutch and fan technology, applied in clutches, fluid clutches, machines/engines, etc., can solve the problems of control accuracy limitation, response time lag, etc., to achieve accurate control, rapid response, and great significance for energy saving and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

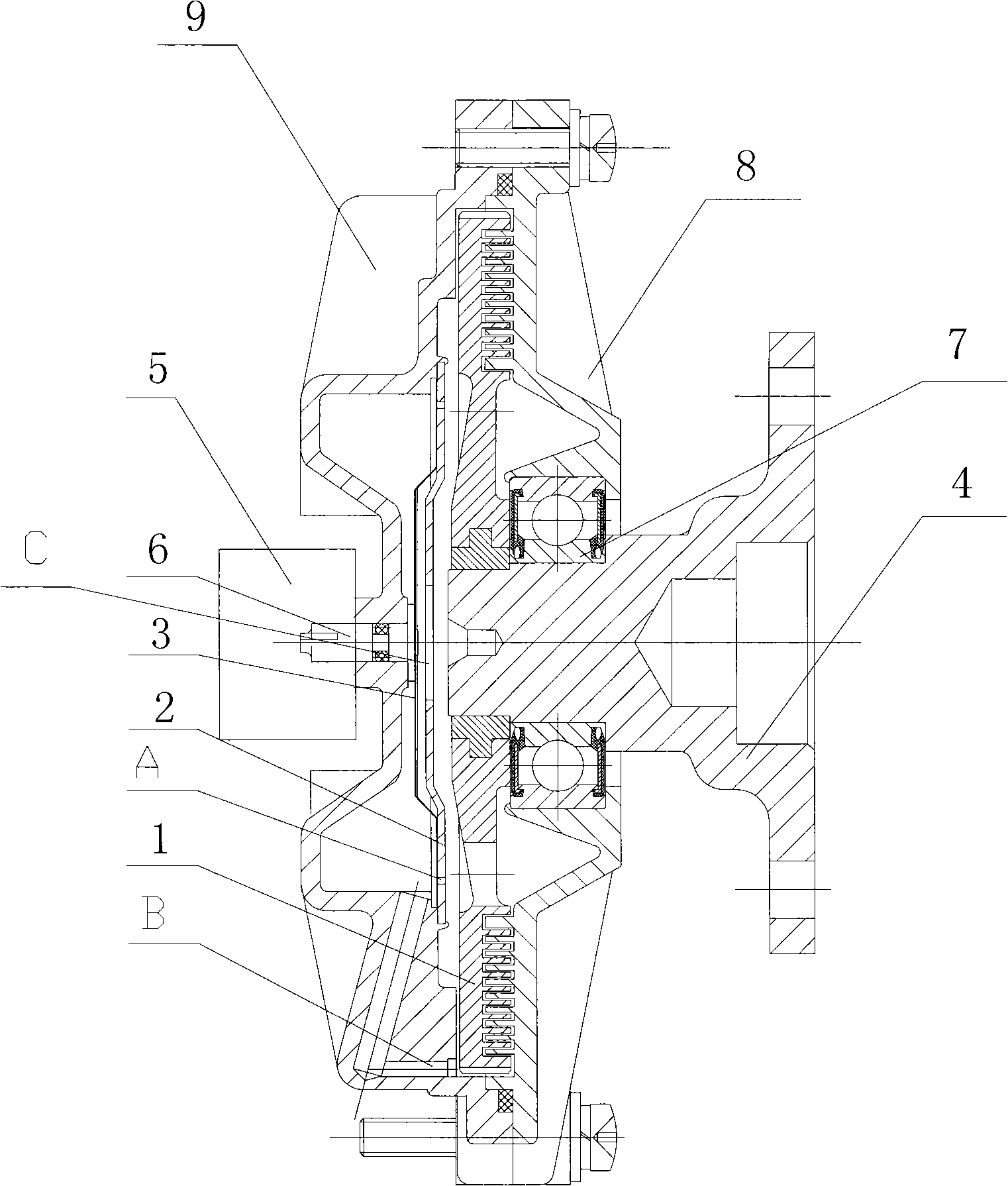

[0012] The accompanying drawings show the structure of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings. The silicone oil fan clutch includes a housing 8, a front cover 9, a driving plate 1, a driven plate 2, a valve plate 3, a driving shaft 4, a temperature sensor (not shown in the figure), a valve plate shaft 6, a bearing 7, a fan And other composition. The front end of the valve disc shaft 6 is equipped with a control unit that enables the valve disc 3 to open or close the oil inlet A, the cavity between the driven plate 2 and the front cover 9 is an oil storage tank, and the driven plate 2 The labyrinth cavity between the housing 8 is a working cavity, the active plate 1 is connected with the active shaft 4, and the control unit is composed of an executive component, a temperature sensor and an ECU. The temperature sensor can be a precision...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com