Blood gas analyzer quality control serum production process

A technology of blood gas analyzer and production method, which is applied in the field of blood gas analyzer quality control products, and can solve the problems that the gas concentration cannot reach the expected value and affect product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The production process steps are as follows:

[0034] 1) Prepare quality control liquid, its main components and concentrations are as follows:

[0035] name

[0036] 2) Prepare mixed balance gas:

[0037] In order to meet the gas requirements, we use a mixture of pCO2 of 57mmHg, pO2 of 40mmHg and nitrogen as the balance gas as the filling gas for the sealed bottle. The reason why the gas partial pressure range of the balance gas is slightly wider than the required range of the quality control substance is that when the balance gas and the gas in the liquid reach equilibrium, the gas partial pressure in the liquid can reach our pre-designed range.

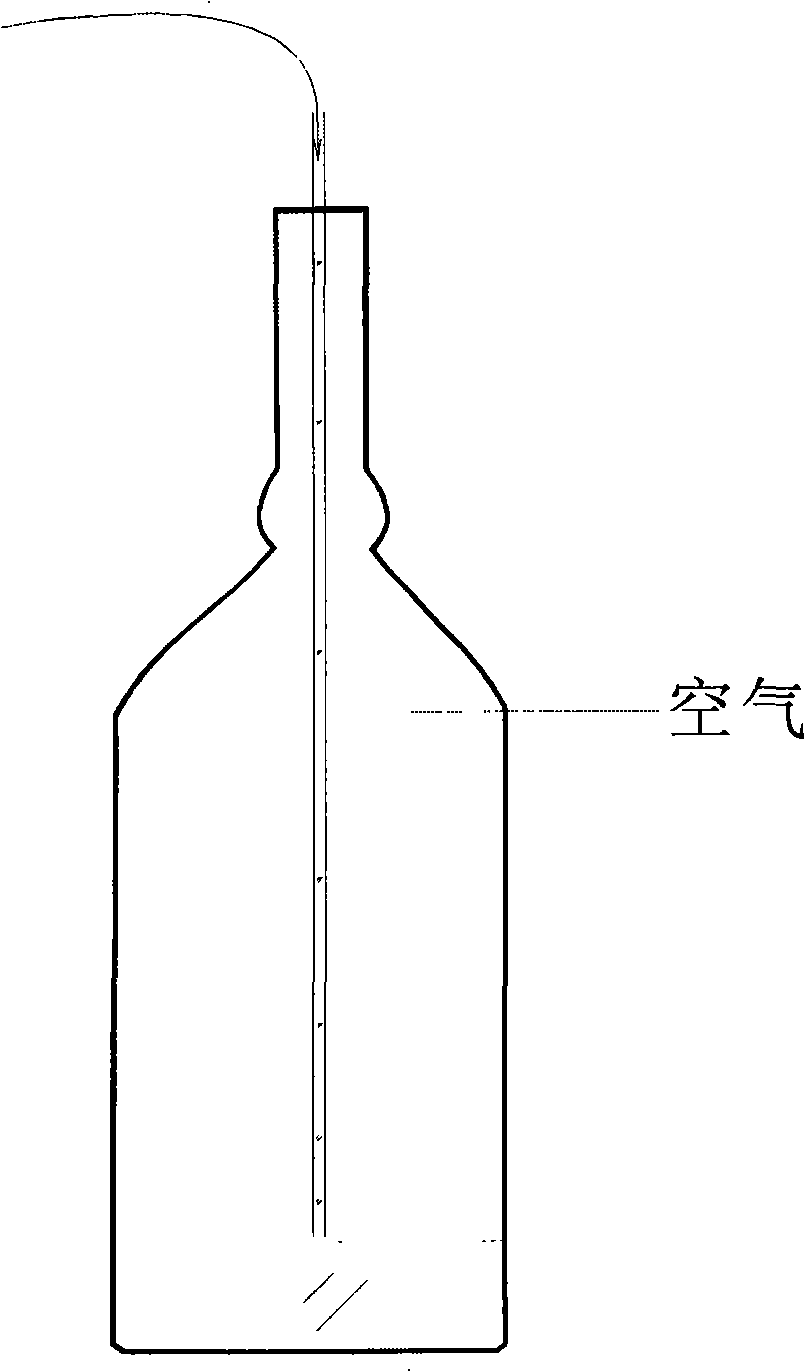

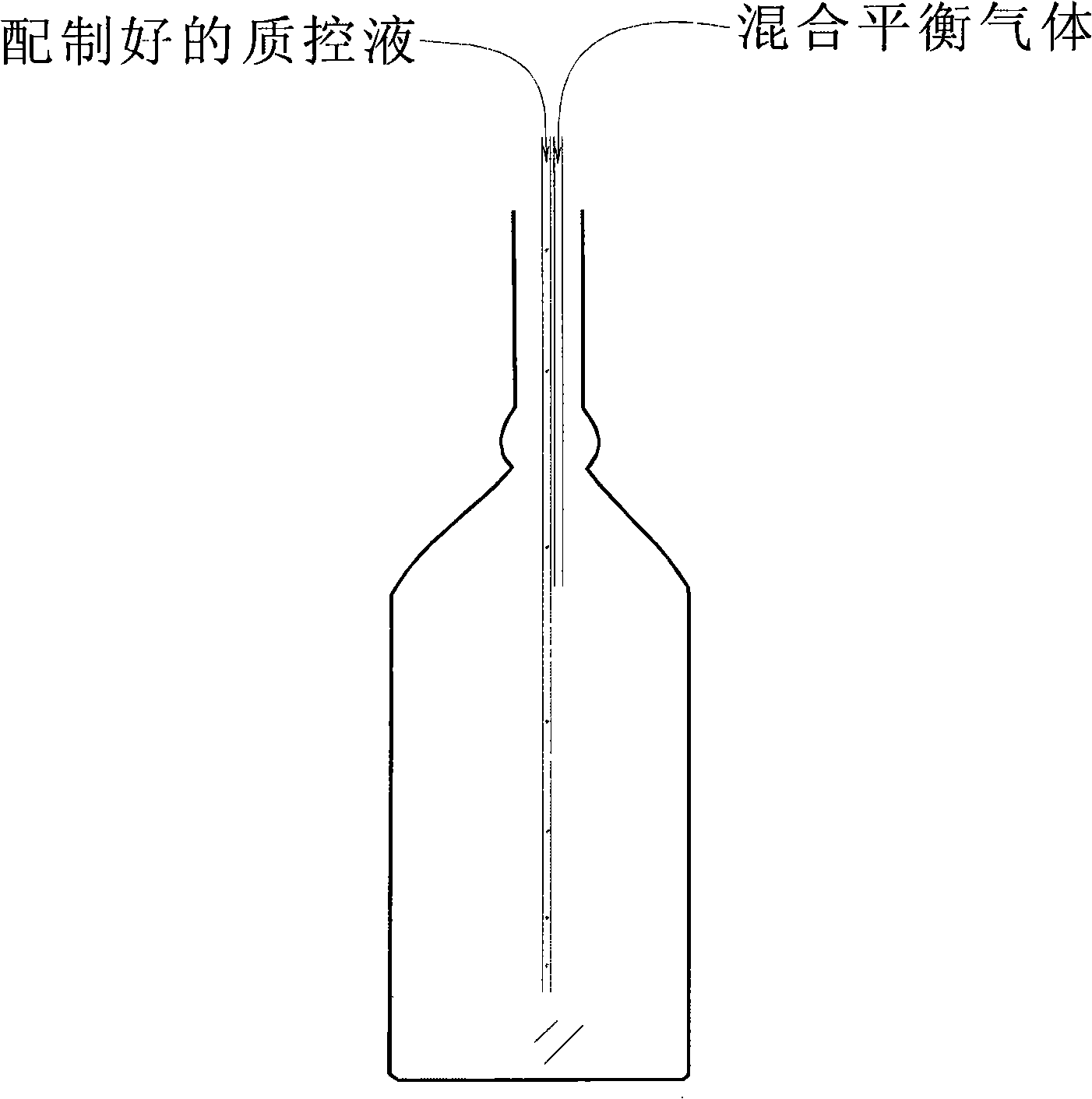

[0038] 3) Filling:

[0039] Connect the prepared quality control liquid and gas into the corresponding pipeline for filling: the gas is injected into the ampoule first, after the existing air in the bottle is driven out of the bottle mouth, the injection is continued, and then the liquid is injected.

[0040] 4)...

Embodiment 2

[0046] The production process steps are as follows:

[0047] 1) Prepare quality control liquid, its main components and concentrations are as follows:

[0048] name

[0049] 2) Prepare mixed balance gas:

[0050] In order to meet the gas requirements, we use a mixture of pCO2 of 67mmHg, pO2 of 44mmHg and nitrogen as the balance gas as the filling gas for the sealed bottle. The reason why the gas partial pressure range of the balance gas is slightly wider than the required range of the quality control substance is that when the balance gas and the gas in the liquid reach equilibrium, the gas partial pressure in the liquid can reach our pre-designed range.

[0051] 3) Filling:

[0052] Connect the prepared quality control liquid and gas into the corresponding pipeline for filling: the gas is injected into the ampoule first, after the existing air in the bottle is driven out of the bottle mouth, the injection is continued, and then the liquid is injected.

[0053] 4)...

Embodiment 3

[0059] The production process steps are as follows:

[0060] 1) Prepare quality control liquid, its main components and concentrations are as follows:

[0061] name

[0062] 2) Prepare mixed balance gas:

[0063] In order to meet the gas requirements, we use a mixture of pCO2 of 60mmHg, pO2 of 38mmHg and nitrogen as the balance gas as the filling gas for the sealed bottle. The reason why the gas partial pressure range of the balance gas is slightly wider than the required range of the quality control substance is that when the balance gas and the gas in the liquid reach equilibrium, the gas partial pressure in the liquid can reach our pre-designed range.

[0064] 3) Filling:

[0065] Connect the prepared quality control liquid and gas into the corresponding pipeline for filling: the gas is injected into the ampoule first, after the existing air in the bottle is driven out of the bottle mouth, the injection is continued, and then the liquid is injected.

[0066] 4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com