Air purification method combined of adsorption and heat catalytic oxidation regeneration in situ

A catalytic oxidation and thermal catalysis technology, applied in the fields of public health and environmental protection, to overcome the inability to directly reuse air, overcome high energy consumption, save investment and increase operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

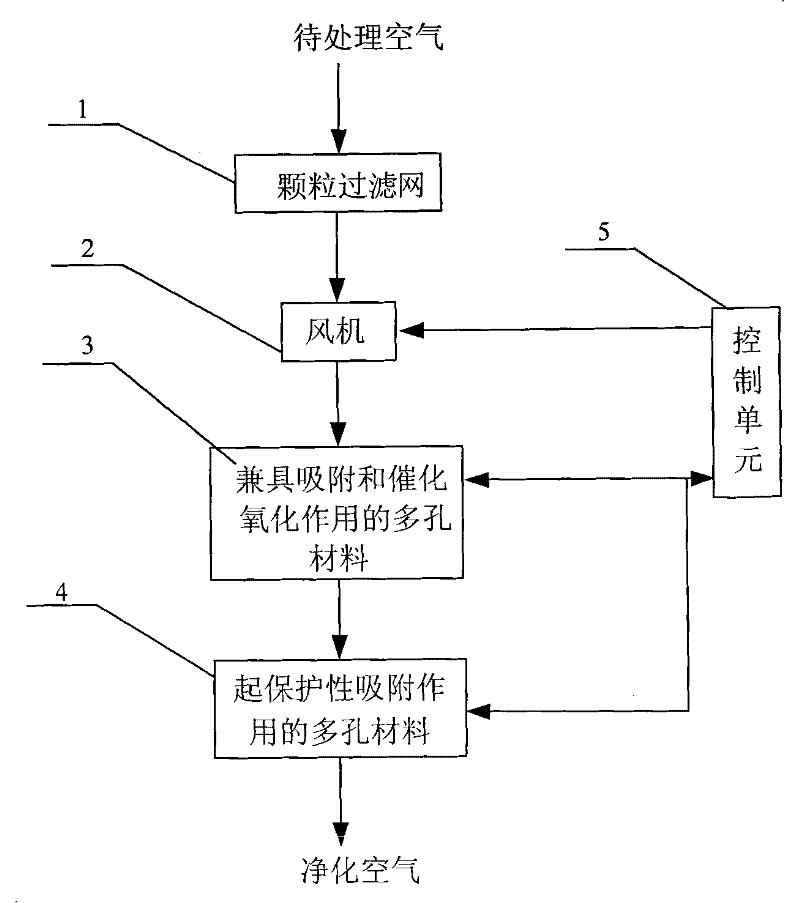

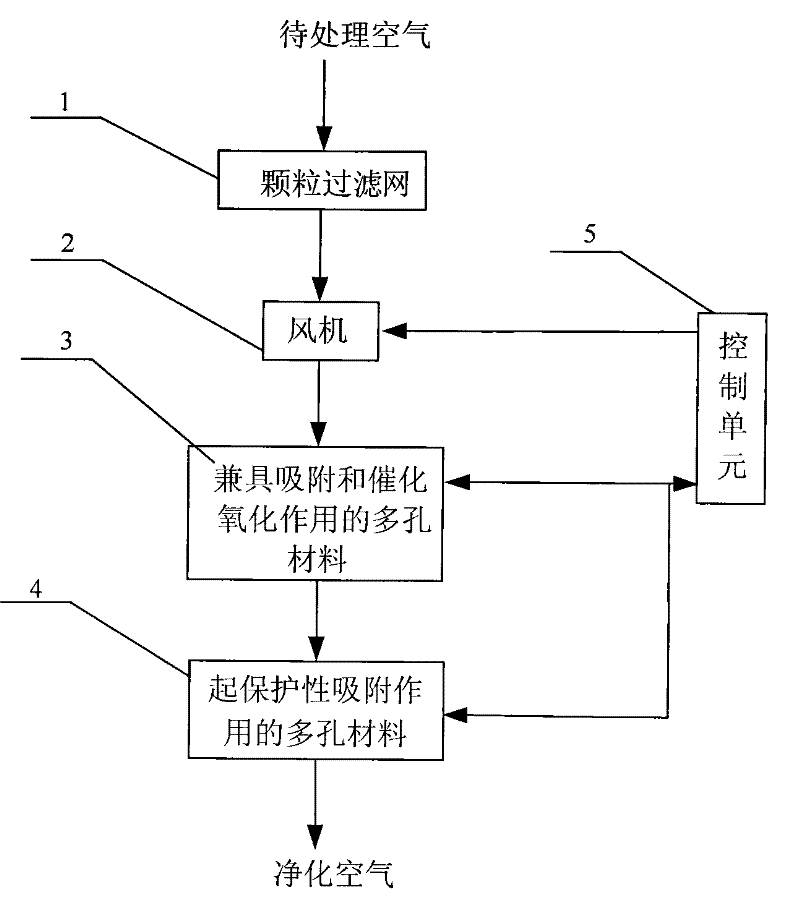

Method used

Image

Examples

Embodiment 1

[0035] (1) The air to be treated contains 2.12mg / m 3 Formaldehyde, 10.11mg / m 3 Benzene series (2.21mg / m 3 Benzene, 6.11mg / m 3 Toluene and 1.79mg / m 3 xylene), the air to be treated first passes through the particle filter 1 under the suction of the blower fan 2 to remove the particles mixed in the air.

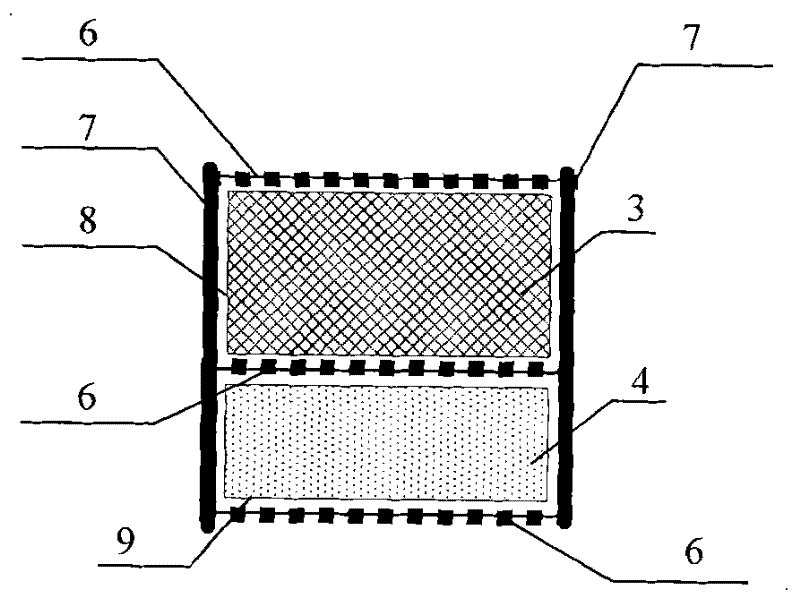

[0036] (2) Utilize the porous material 3 with both adsorption and catalytic functions and the porous material 4 with protective adsorption function to adsorb low-concentration formaldehyde and benzene series in the air.

[0037] The porous material 3 with both adsorption and catalytic functions is activated alumina loaded with 0.5% Pt (Pt / Al 2 o 3 ); The porous material 4 that plays a protective adsorption role is activated carbon particles (Mn / AC) impregnated with 1% manganese oxide.

[0038] The air filtered by the particle filter 1 first passes through the Pt / Al 2 o 3 , and then through Mn / AC, the space velocity is 3×10 4 h -1 .

[0039] (3) monitor the concentrat...

Embodiment 2

[0045] (1) The air to be treated contains 3.20mg / m 3 Formaldehyde, 8.10mg / m 3 Benzene series (0.96mg / m 3 Benzene, 2.58mg / m 3 Toluene and 4.56mg / m 3 xylene), the air to be treated first passes through the particle filter 1 under the suction of the blower fan 2 to remove the particles mixed in the air.

[0046] (2) Utilize the porous material 3 with both adsorption and catalytic functions and the porous material 4 with protective adsorption function to adsorb low-concentration formaldehyde and benzene series in the air.

[0047] The porous material 3 with both adsorption and catalytic functions is 13X molecular sieve (Au / 13XMS) loaded with 2% Au; the porous material 4 with protective adsorption function is activated carbon particles (AC).

[0048] The air filtered by particle filter 1 first passes through Au / 13XMS, and then passes through AC with a space velocity of 3×10 4 h -1 .

[0049] (3) With the help of instruments or people's sense of smell, the concentration of fo...

Embodiment 3

[0055] (1) The air to be treated contains 4.1mg / m 3 Formaldehyde, 8.10mg / m 3 Benzene series (0.96mg / m 3 Ethylbenzene, 6.58mg / m 3 Styrene and 0.56mg / m 3 Cumene), the air to be treated first passes through the particle filter 1 under the suction of the blower fan 2 to remove the particles mixed in the air.

[0056] (2) Utilize the porous material 3 with both adsorption and catalytic functions and the porous material 4 with protective adsorption function to adsorb low-concentration formaldehyde and benzene series in the air.

[0057] The porous material 3 with both adsorption and catalytic functions is titanium dioxide loaded with 1% Pt (Pt / TiO 2 ); the porous material with protective adsorption is activated carbon fiber (Mn / ACF) impregnated with 6% manganese oxide on the surface.

[0058] The air filtered by the particle filter 1 first passes through the Pt / TiO 2 , and then through Mn / ACF, the space velocity is 3×10 4 h -1 .

[0059] (3) With the help of instruments or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com