Filling material special for producing C-13 isotope with CO cryogenic rectification method

A low-temperature rectification and isotope technology, which is applied in the separation, separation methods, chemical instruments and methods of different isotopic elements, etc., can solve problems such as unfavorable large column diameter efficiency, and achieve the effect of small pressure drop, high separation efficiency and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

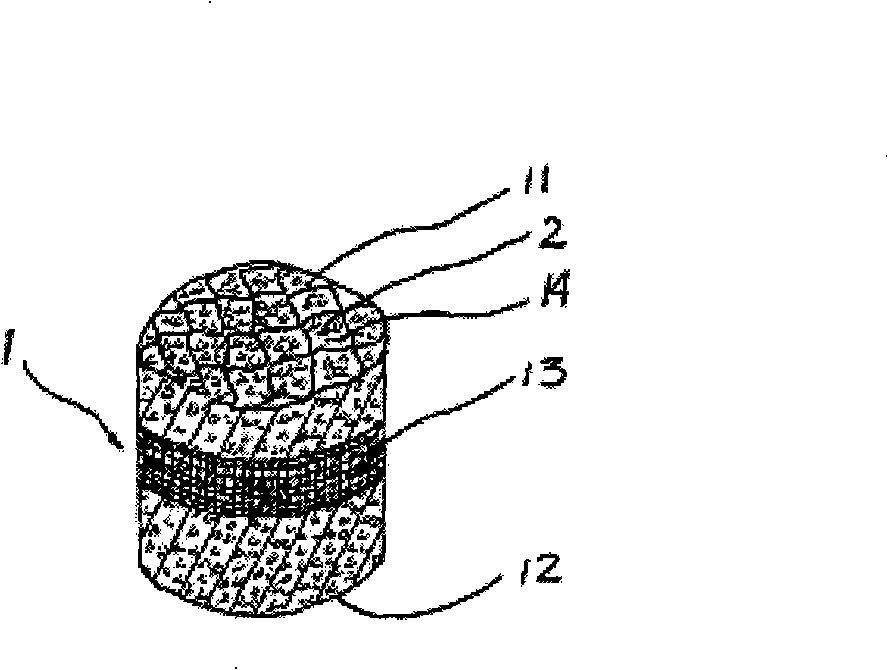

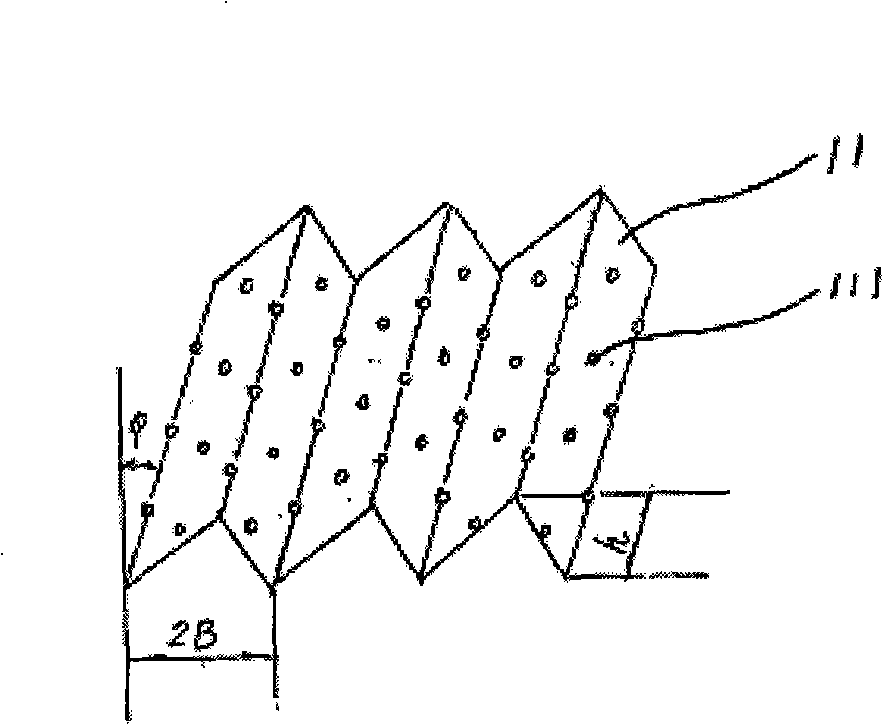

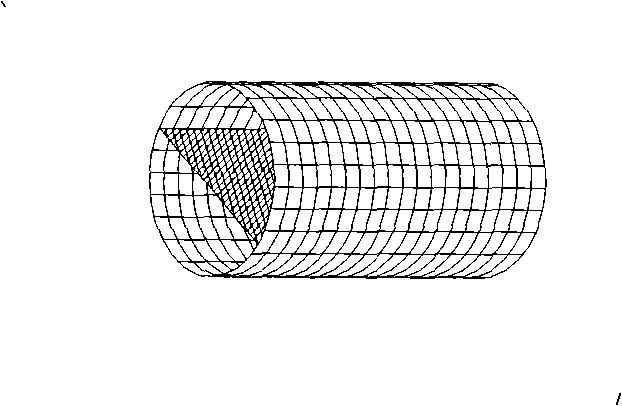

[0027] Such as Figure 1~3 shown, PACK- 13 C packing, including disc packing 1 and particle packing 2, described disc packing 1 comprises a plurality of corrugated sheets 11 pressed by stainless steel wire mesh, stainless steel wire mesh tray 12 and stainless steel wire mesh outer frame 13, the described A plurality of stainless steel wire mesh corrugated sheets 11 are vertically arranged in the above-mentioned stainless steel wire mesh outer frame 13, and the corrugated directions of two adjacent corrugated sheets are opposite, and the stainless steel wire mesh tray 12 is arranged on the vertically arranged stainless steel wire mesh corrugated sheets At the bottom, the stainless steel wire mesh corrugated sheet 11 is an inclined corrugated sheet, the peak line or valley line of the corrugated sheet has an inclination angle with the vertical axis of the packing pan, and the stainless steel wire mesh corrugated sheet 11 is provided with a plurality of small holes 111, multiple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com