Process for biological oxidation treatment of waste gas containing nitrogen oxide

A technology of nitric oxide and biological oxidation, which is applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as cost problems, and achieve the effects of small pressure drop of packing, simple operating conditions, economical and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] step:

[0027] (1) Add culture medium to activated sludge (5L), which contains (NH 4 ) 3 SO 4 (10g), FeSO 4 (1g), K 2 HPO 4 (5g), MgSO 4 (2.5g), NaCl (10g), CaCO 3 (5g), and add 133.93mg / m mixed in a mass ratio of 5:1 3 NaNO 2 -N and 2.67mg / m 3 K 2 HPO 4 - Nutrient solution mixture of P, NaNO 2 and K 2 HPO 4 They are respectively used as nitrogen source and phosphorus source, and then continuous aeration is carried out in the culture bottle at a temperature of 25°C, and oxygen is continuously introduced to domesticate and cultivate the nitrifying bacteria in the activated sludge.

[0028] (2) After about 20 days, the target product (NaNO 3 ) appears, continue to culture, add 5g of glucose, enrich culture.

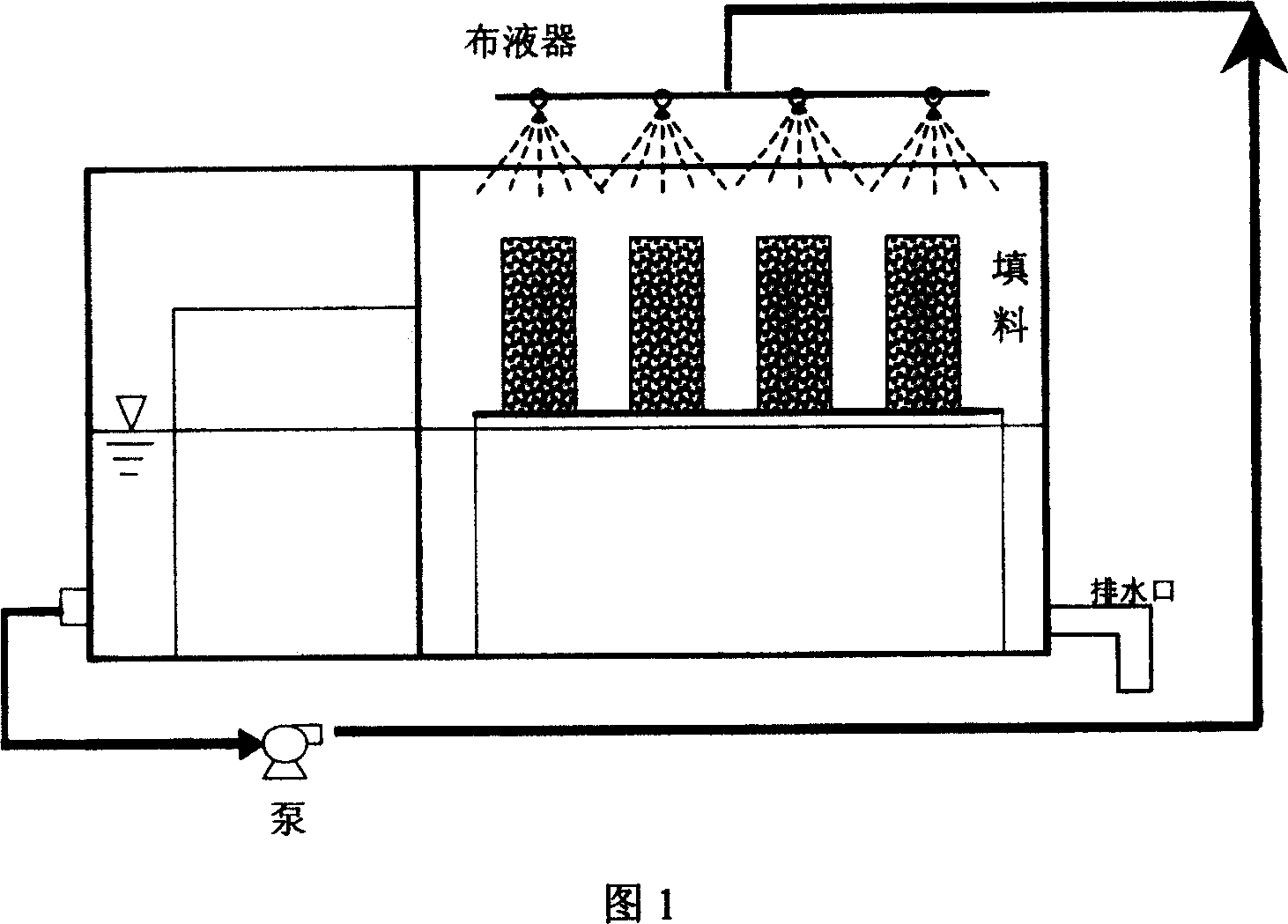

[0029] (3) Film-hanging stage: Pour the bacterial solution obtained in step (2) into the inoculation basin, which is made of plexiglass, as shown in Figure 1, the bacterial solution is pressurized by the pump, and then sprinkled to the On the biofil...

Embodiment 2

[0033] step:

[0034] (1) Add medium to the extract mixture (5L) of soil and water around exhaust gas pollution, which contains (NH 4 ) 3 SO 4 (10g), FeSO 4 (1g), K 2 HPO 4 (5g), MgSO 4 (2.5g), NaCl (10g), CaCO 3 (5g), and add 133.93mg / m mixed in a mass ratio of 5:1 3 NaNO 2 -N and 2.67mg / m 3 K 2 HPO 4 - Nutrient solution mixture of P, NaNO 2 and K 2 HPO 4 They are respectively used as nitrogen source and phosphorus source, and then continuous aeration is carried out in the culture bottle at a temperature of 25°C, and oxygen is continuously introduced to domesticate and cultivate the nitrifying bacteria in the activated sludge.

[0035] (2) After about 15 days, the target product (NaNO 3) appeared, continue to culture, add 5g of glucose, and enrich the culture.

[0036] (3) Film-hanging stage: Pour the domesticated bacterial solution into the inoculation basin, which is made of plexiglass, as shown in Figure 1. The filler is a porous carbonaceous material na...

Embodiment 3

[0040] step:

[0041] (1) In 5L medium containing (NH 4 ) 3 SO 4 (10g), FeSO 4 (1g), K 2 HPO 4 (5g), MgSO 4 (2.5g), NaCl (10g), CaCO 3 (5g), add 50mL of a mixture of nitrifying bacteria strains and activated sludge supernatant in a mass ratio of 1:1, and add 133.93mg / m3 mixed in a mass ratio of 5:1 3 NaNO 2 -N and 2.67mg / m 3 K 2 HPO 4 - Nutrient solution mixture of P, NaNO 2 and K 2 HPO 4 They are respectively used as nitrogen source and phosphorus source, and then continuous aeration is carried out in the culture bottle at a temperature of 25°C, and oxygen is continuously introduced to domesticate and cultivate the nitrifying bacteria in the activated sludge.

[0042] (2) After about 15 days, the target product (NaNO 3 ) appeared, continue to cultivate, add a certain amount of 5g of glucose, and enrich the culture.

[0043] (3) Film-hanging stage: Pour the bacterial solution obtained in step (2) into the inoculation basin, which is made of plexiglass, as sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com