Vacuum feed port ceramic sealing structure of ion-turbulent resonance heating antenna

An ion cyclotron resonance and antenna technology, which is applied in the field of ion cyclotron resonance heating antenna vacuum feeder ceramic sealing structure, can solve the problems of high welding success rate, low welding cost, and cracking of insulating ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

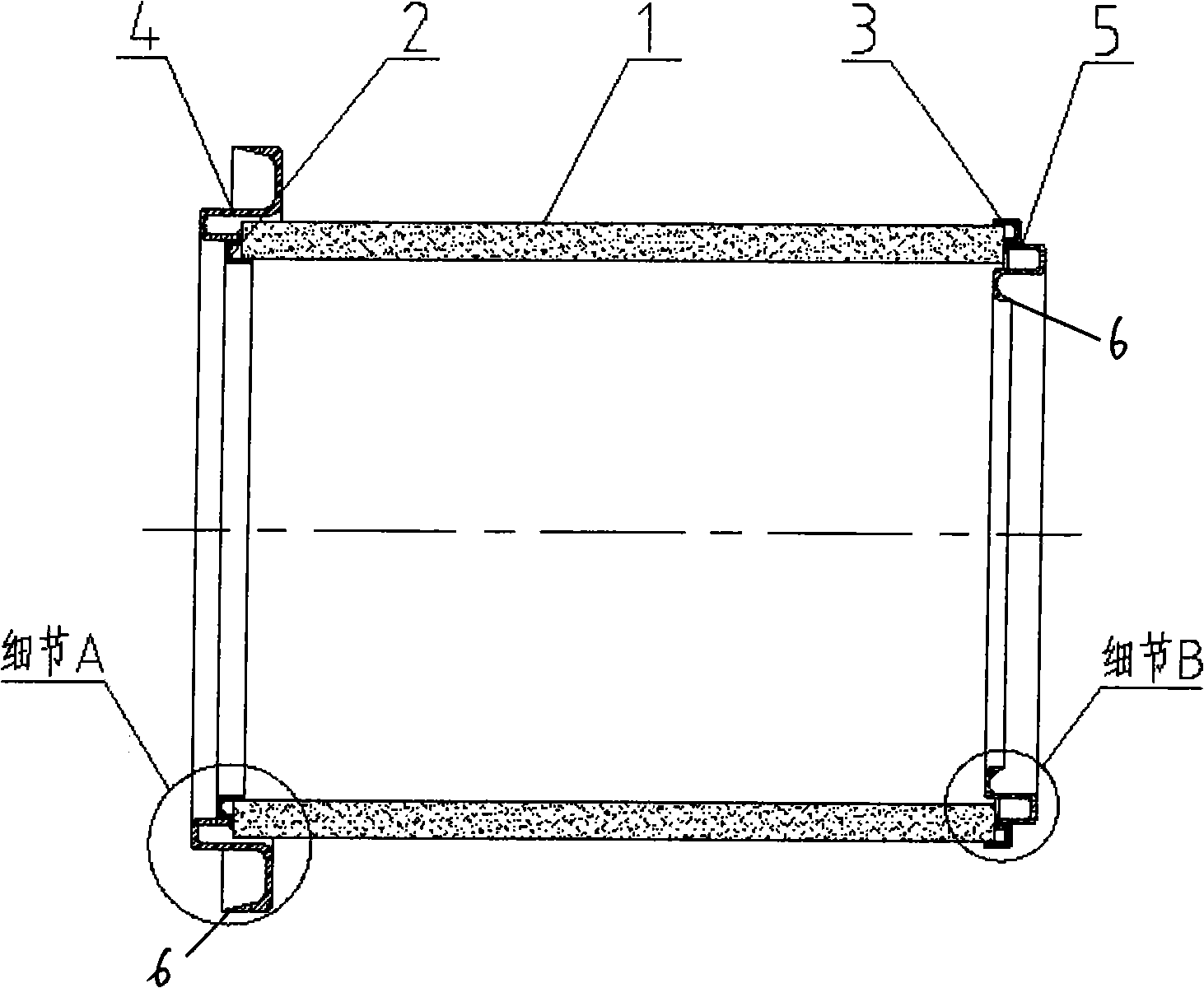

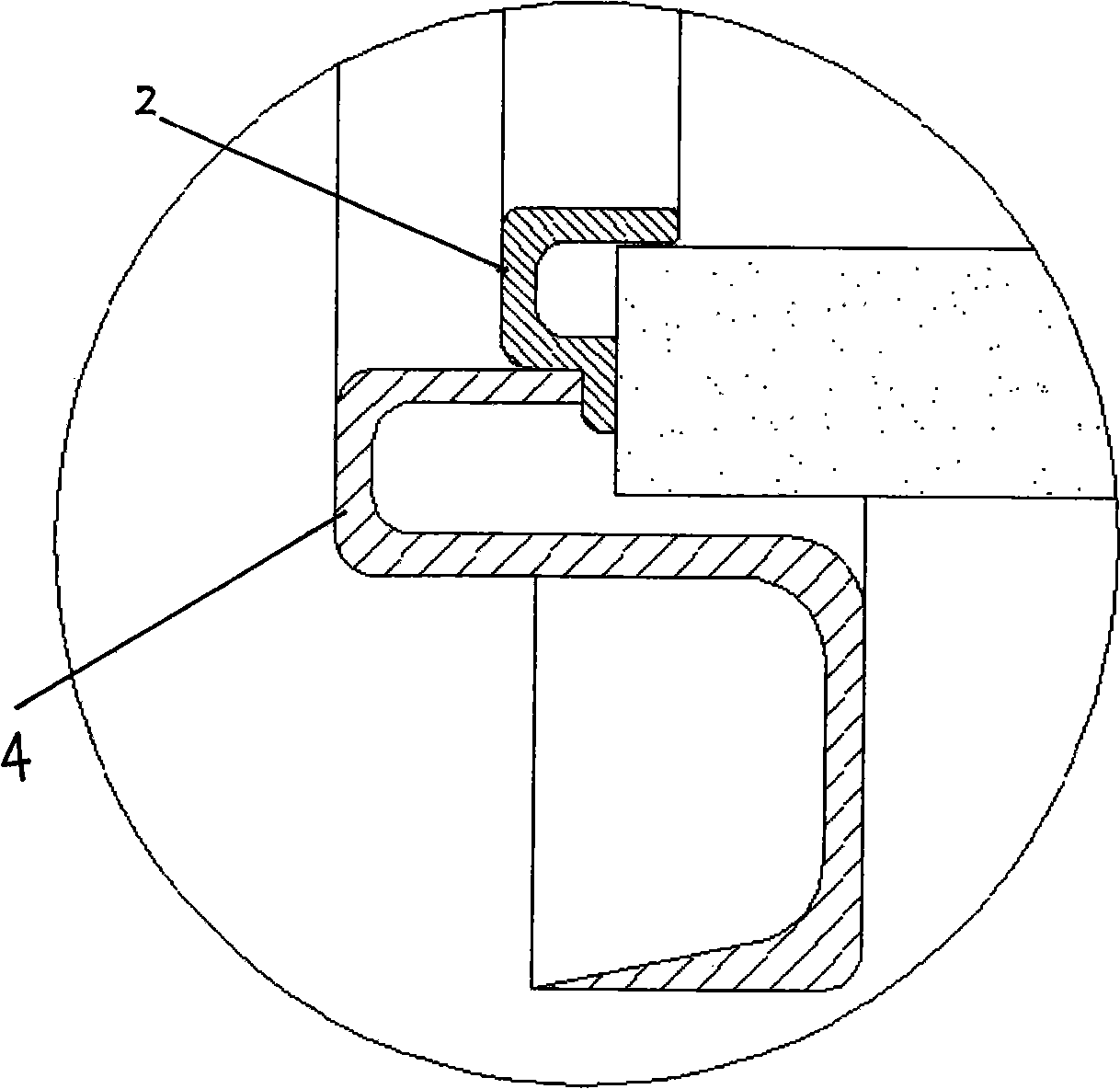

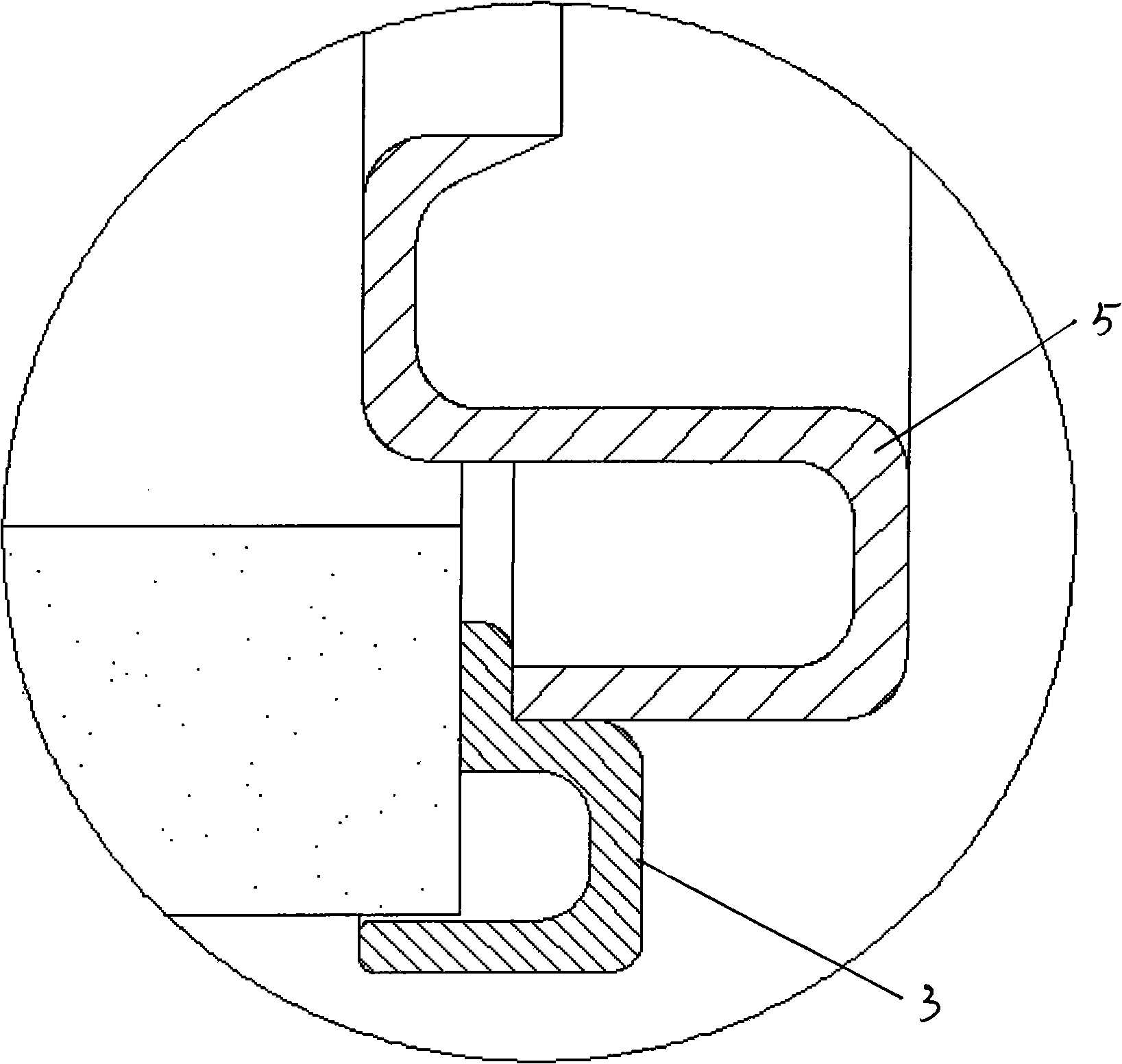

[0011] Ion cyclotron resonance heating antenna vacuum feeder ceramic sealing structure, including 95 insulating cylindrical ceramic tubes 1, the left and right end faces of the ceramic tube 1 are metallized end faces, which have undergone metallization treatment, and the left and right ends of the ceramic tube are respectively set first. The oxygen-free copper flange 2, the second oxygen-free copper flange 3, the first oxygen-free copper flange 2, and the second oxygen-free copper flange 3 respectively have a ring-shaped outer edge, a ring-shaped inner edge, and ceramic tube 1 left 1. Place a layer of vacuum brazing solder between the metallized end faces at the right end, and then respectively set "self A layer of vacuum brazing solder is also placed between the contact surfaces of the first and second stainless steel sealing flanges 4 and 5 in the shape of ", and finally placed in a vacuum brazing furnace in a vertical manner for welding. The first and second stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com