Silane treatment technique before electrostatic powder spraying of metal

A technology of electrostatic powder and process method, which is applied in the direction of metal material coating process, pretreatment surface, coating, etc., can solve the problems such as the method of silane treatment and the method of steel treatment that have not been mentioned, and save equipment investment , Save production space and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

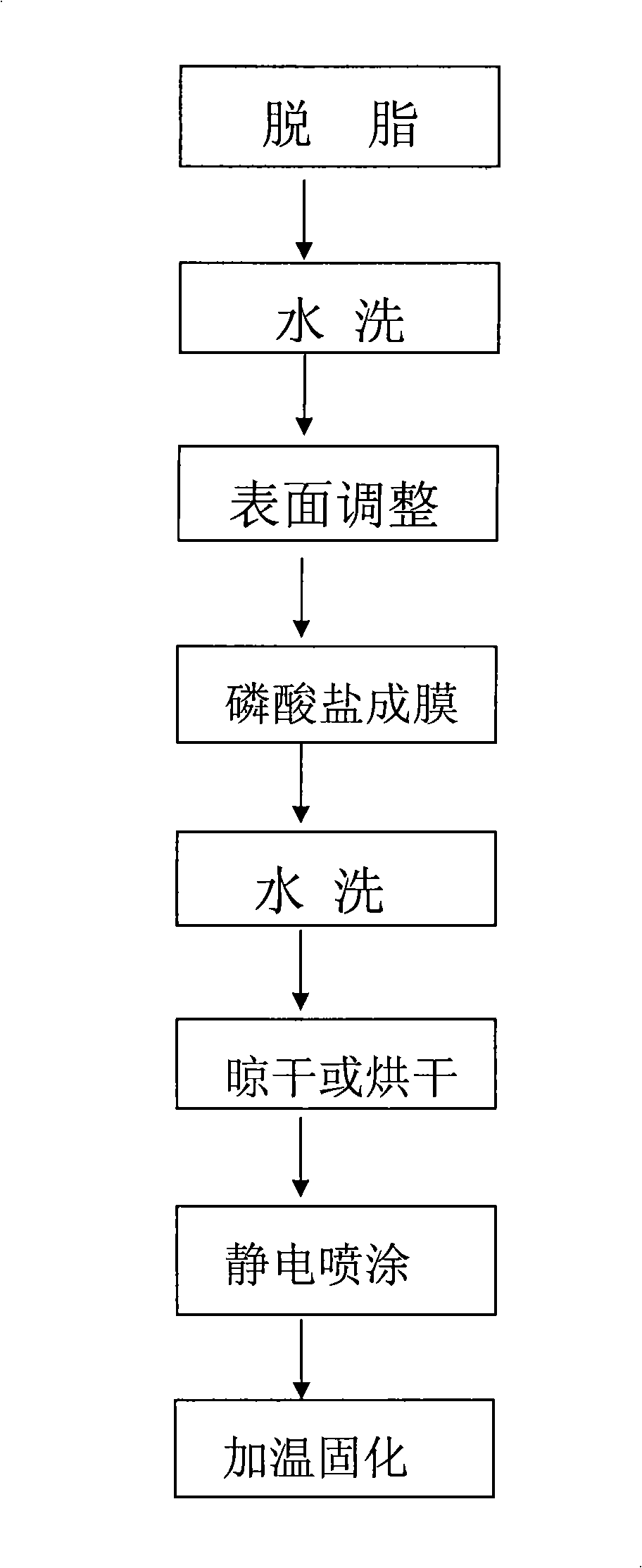

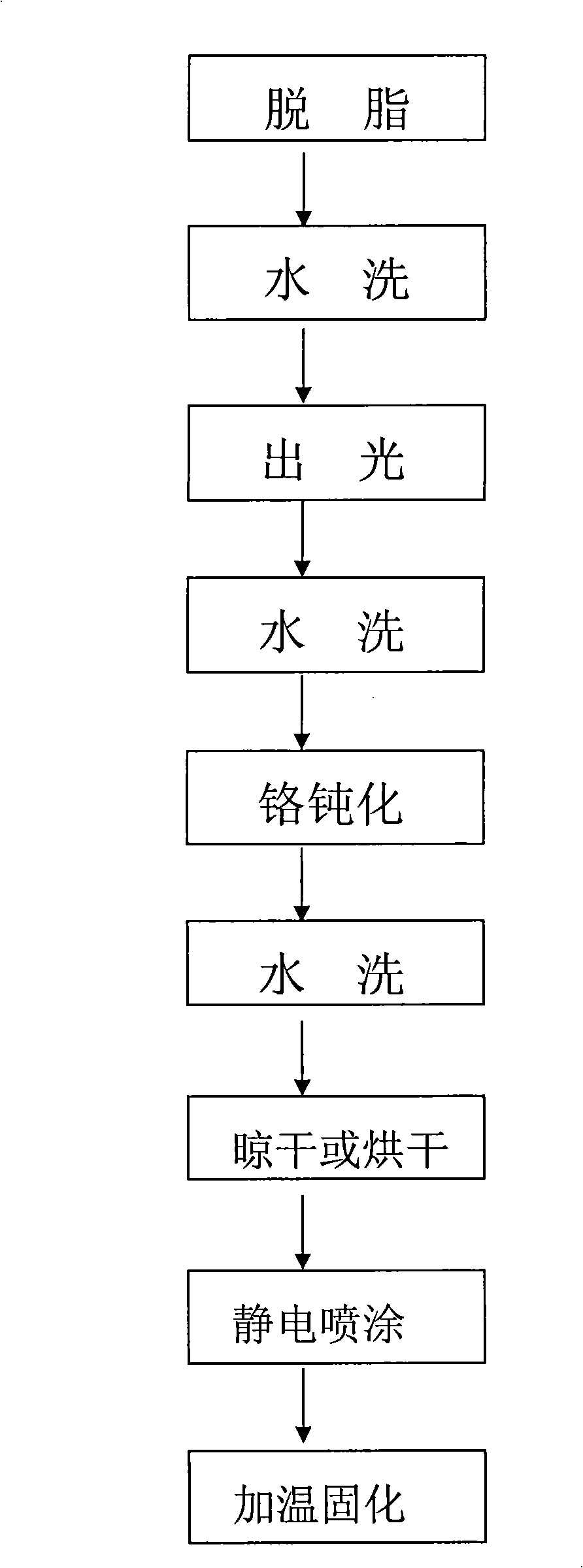

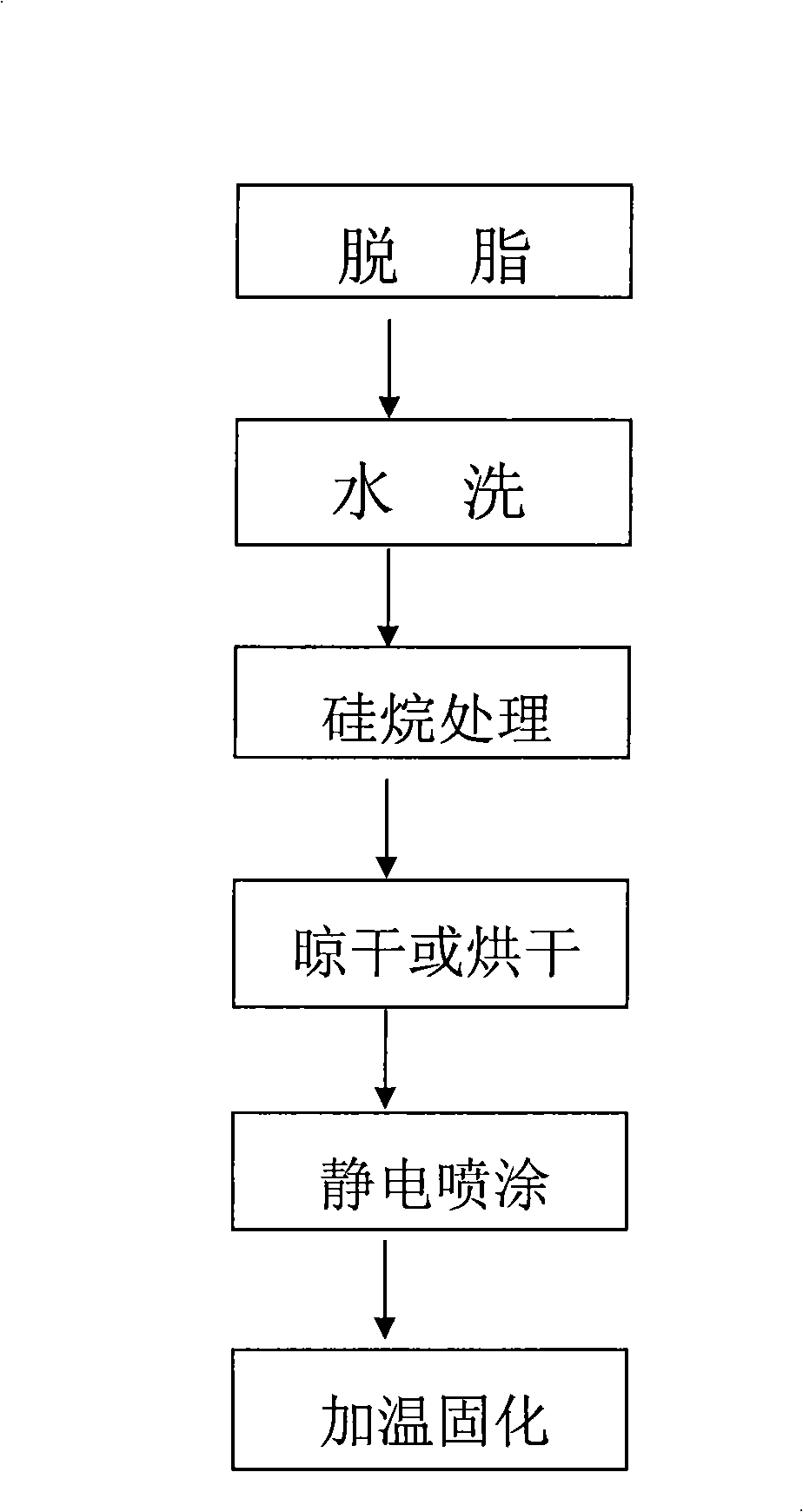

Method used

Image

Examples

Embodiment 1

[0046] Take 700g of deionized water, take 4g of acetic acid, 40g of ethanol, add to deionized water, fully stir and mix evenly; take 10g of vinyltriethoxysilane, add to deionized water, fully stir and mix; take 10g of aminopropyl triethyl Add oxysilane into water, stir well; take 5g of propyltriethoxysilane isocyanate, add it into water, stir well; add water to 1000g. Use the composite treatment liquid to treat the surface of iron parts, zinc parts and aluminum parts, which can be dipped, sprayed and rolled. The color of the silane film is uniform, and the coating adhesion is good after electrostatic powder spraying.

Embodiment 2

[0048] Take 700g of deionized water, take 8g of acetic acid, 60g of ethanol, add them to deionized water, stir and mix well; take 5g of propyltriethoxysilane, add it to water, stir well; take 20g of vinyltriethoxysilane , add to deionized water, fully stir and mix; take 15g of aminopropyltriethoxysilane, add to water, fully stir evenly; take 10g of isocyanate propyltriethoxysilane, add to water, fully stir evenly; 1000g. Use the composite treatment liquid to treat the surface of iron parts, zinc parts and aluminum parts, which can be dipped, sprayed and rolled. The color of the silane film is uniform, and the coating adhesion is good after electrostatic powder spraying.

Embodiment 3

[0050] Take 700g of deionized water, take 12g of acetic acid, 80g of ethanol, add them to deionized water, stir and mix well; take 10g of propyltriethoxysilane, add it to water, stir well; take 30g of vinyltriethoxysilane , add to deionized water, fully stir and mix; take 20g of aminopropyltriethoxysilane, add to water, fully stir evenly; take 15g of isocyanate propyltriethoxysilane, add to water, fully stir evenly; 1000g. Use the composite treatment liquid to treat the surface of iron parts, zinc parts and aluminum parts, which can be dipped, sprayed and rolled. The color of the silane film is uniform, and the coating adhesion is good after electrostatic powder spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com